You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

first time welding outer rocker on unibody car. help?

- Thread starter mignoob

- Start date

okay, my pinch weld along the rocker/sill bottom isn't in the best condition either. I've got it straightened out but some sections could use some replacing (just because they have rusted away some from the bottom, looks okay at the top at the joint). is it ok to cut out some small sections here and there (1-2 inches) and replace some of the worse sections? I know that the pinch weld is where all the panels meet so I'm not sure if I should just leave it alone or not. I have enough material and good, sturdy areas to plug weld the new rocker to and have converted the rust on the pinch weld as best I can (sprayed it multiple times to get all the nooks and crannies) so I'm thinking I could just leave it if I have to. I just want to make it a little more sturdy as the car is going to be a drift car, its probably fine but if I can make it stronger a little in this process then might as well. thanks for all the help guys.

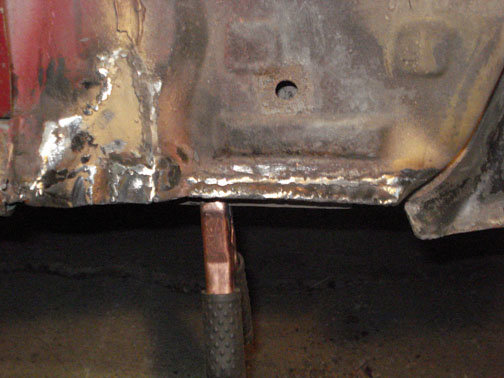

ok, now pictures... this is the front corner I have been working on. I have not ground down the welds all the way as the fender covers this section anyway. I'm not done with the bottom yet but its already twice as strong as it was previously. sorry about the image size, I resized them but they seem to still be big.

this is the back corner, in front of the rear wheel well. the worse section on the car. should be easy though as there is so much gone, I can just make rectangular sections to weld in. the opening on the side was pulled off by hand with very little force. it was all rust and an inch of bondo and body filler from previous owner.