My first project

Looked around for a welding trolley but nothing out there but the Clarke and didnt fancy that, so decided to go for it. Wanted something that I could wheel around easily without falling apart, quite narrow to squeeze down one side of my garage, and with a low centre of gravity to avoid tipping.

Used 1" square tube, some 20mm wide by 3mm steel, and some twin-slot shelving rail that I had laying around in the garage. Purchased the rubber wheels and a 90deg clamp from Axminster for a few pounds each and tube ends from Ebay. Cut and bent everything by hand. Primed and Enameled by hand. Used just under 3m of tube and about 1.5m of the 20mm flat.

Practiced welding a little first on flat steel first and then started on the H-frame section. After clamping the first two pieces at 90deg, tack welded one surface. Then just went for it, welding each surface with two short runs...

Oops, was no longer at 90degrees seems to have pulled to one side. I suppose tacking all the way around might have been the way to do it, anyone??? Some welds were not as nice as I would have liked either; I found it difficult to get the torch angle right in all positions around the tube and penetrate into both sides of the join. To be honest, I found it difficult to get good penetration, even on a higher setting (on steel sheet with 0.6mm wire, I have my Mig 170 set to #2 & 4.5 wire speed for 2mm and #3 & 4.5 for 3mm. BTW, my butt joins stink on 1mm with any setting but lap joins are good on #1 & 4.5

seems to have pulled to one side. I suppose tacking all the way around might have been the way to do it, anyone??? Some welds were not as nice as I would have liked either; I found it difficult to get the torch angle right in all positions around the tube and penetrate into both sides of the join. To be honest, I found it difficult to get good penetration, even on a higher setting (on steel sheet with 0.6mm wire, I have my Mig 170 set to #2 & 4.5 wire speed for 2mm and #3 & 4.5 for 3mm. BTW, my butt joins stink on 1mm with any setting but lap joins are good on #1 & 4.5  )

)

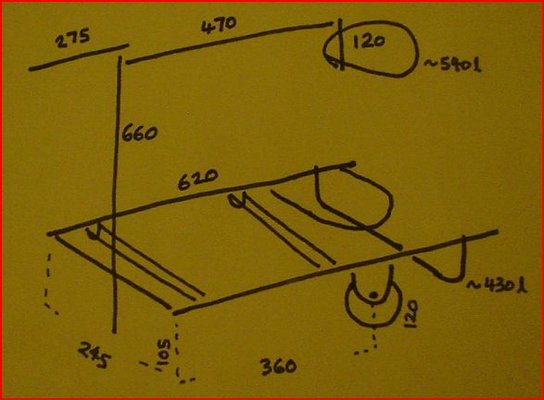

See photos and diagram for the results. The welder sits on the H-frame; its feet sit in the U-section stuff to position it on the frame. The H-frame sits at an angle to give slightly better access to the welder controls. However, the main vertical section and bottle are at 90deg from ground and the higher horizontal section is level; I cut a slot in the vertical to effectively hook on to the H-frame section to give a stronger less-stressed join and to get those angles. The gas bottle sits to one side at the front of the welder, as you can see. This offers a certain amount of protection for that loooong Euro torch connector. The wheels were positioned to balance and take the weight when moving it around, it takes no effort at all. BTW. the excess holes were already in the steel that I used....

It all worked out pretty nicely, I think, cost me about £20 in parts and paint (buying the steel would add £12-ish to the cost) and fits down the side of the garage nicely I plan to add a tray or two for my clamps etc. and some hooks to hold the gun and cables at some point. Got to work out the best way to bend a tray into shape by hand now...

I plan to add a tray or two for my clamps etc. and some hooks to hold the gun and cables at some point. Got to work out the best way to bend a tray into shape by hand now...

All comments, questions and pro tips welcomed!!

Looked around for a welding trolley but nothing out there but the Clarke and didnt fancy that, so decided to go for it. Wanted something that I could wheel around easily without falling apart, quite narrow to squeeze down one side of my garage, and with a low centre of gravity to avoid tipping.

Used 1" square tube, some 20mm wide by 3mm steel, and some twin-slot shelving rail that I had laying around in the garage. Purchased the rubber wheels and a 90deg clamp from Axminster for a few pounds each and tube ends from Ebay. Cut and bent everything by hand. Primed and Enameled by hand. Used just under 3m of tube and about 1.5m of the 20mm flat.

Practiced welding a little first on flat steel first and then started on the H-frame section. After clamping the first two pieces at 90deg, tack welded one surface. Then just went for it, welding each surface with two short runs...

Oops, was no longer at 90degrees

seems to have pulled to one side. I suppose tacking all the way around might have been the way to do it, anyone??? Some welds were not as nice as I would have liked either; I found it difficult to get the torch angle right in all positions around the tube and penetrate into both sides of the join. To be honest, I found it difficult to get good penetration, even on a higher setting (on steel sheet with 0.6mm wire, I have my Mig 170 set to #2 & 4.5 wire speed for 2mm and #3 & 4.5 for 3mm. BTW, my butt joins stink on 1mm with any setting but lap joins are good on #1 & 4.5

seems to have pulled to one side. I suppose tacking all the way around might have been the way to do it, anyone??? Some welds were not as nice as I would have liked either; I found it difficult to get the torch angle right in all positions around the tube and penetrate into both sides of the join. To be honest, I found it difficult to get good penetration, even on a higher setting (on steel sheet with 0.6mm wire, I have my Mig 170 set to #2 & 4.5 wire speed for 2mm and #3 & 4.5 for 3mm. BTW, my butt joins stink on 1mm with any setting but lap joins are good on #1 & 4.5  )

)See photos and diagram for the results. The welder sits on the H-frame; its feet sit in the U-section stuff to position it on the frame. The H-frame sits at an angle to give slightly better access to the welder controls. However, the main vertical section and bottle are at 90deg from ground and the higher horizontal section is level; I cut a slot in the vertical to effectively hook on to the H-frame section to give a stronger less-stressed join and to get those angles. The gas bottle sits to one side at the front of the welder, as you can see. This offers a certain amount of protection for that loooong Euro torch connector. The wheels were positioned to balance and take the weight when moving it around, it takes no effort at all. BTW. the excess holes were already in the steel that I used....

It all worked out pretty nicely, I think, cost me about £20 in parts and paint (buying the steel would add £12-ish to the cost) and fits down the side of the garage nicely

I plan to add a tray or two for my clamps etc. and some hooks to hold the gun and cables at some point. Got to work out the best way to bend a tray into shape by hand now...

I plan to add a tray or two for my clamps etc. and some hooks to hold the gun and cables at some point. Got to work out the best way to bend a tray into shape by hand now...All comments, questions and pro tips welcomed!!