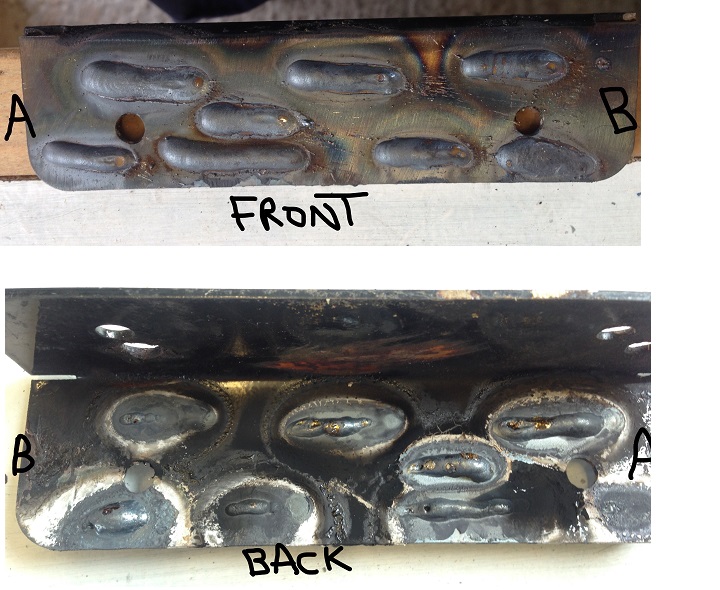

This is my first attempt on a piece of 2mm angle (settings: power 3 / wirefeed 4) - as per r-tech manual.

Seemed to make the right noises, so i guess it was an ok setting.

tip for future self: remove the paint from both sides of steel (yeh i know!!)

Just did straight (stringers?) pushing, no fancy wiggles etc (as opposed to pulls, which to me feels more natural but trying to get into the habit of pushing.

Couple of things, when i watch youtube videos, the puddle is very clear as is the steel round the puddle. It maybe a camera trick thing, but i cant really see the puddle very well, so if the weld was long i could be going in any direction (they look straight-ish, but are only about 1 1/2 inches)

Also, with regards the contact tip, does it make any difference if the tip is flush to the shroud, as it is about 4mm within the shroud. i feel like the shroud is very close to the weld.

A thing ive noticed on the first welds, the profile of the weld starts high (less penetration), then as the weld progresses it penetrates more. (see pic2)

Long winded first post i know, just trying to soak in some expert comments.

thanks

martin

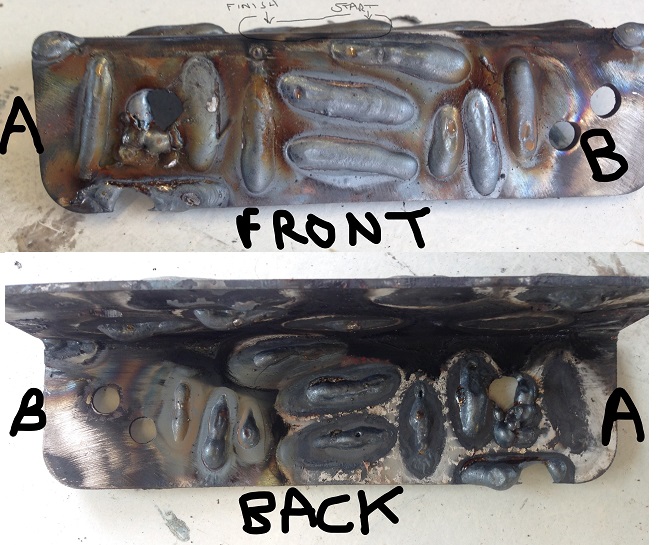

Seemed to make the right noises, so i guess it was an ok setting.

tip for future self: remove the paint from both sides of steel (yeh i know!!)

Just did straight (stringers?) pushing, no fancy wiggles etc (as opposed to pulls, which to me feels more natural but trying to get into the habit of pushing.

Couple of things, when i watch youtube videos, the puddle is very clear as is the steel round the puddle. It maybe a camera trick thing, but i cant really see the puddle very well, so if the weld was long i could be going in any direction (they look straight-ish, but are only about 1 1/2 inches)

Also, with regards the contact tip, does it make any difference if the tip is flush to the shroud, as it is about 4mm within the shroud. i feel like the shroud is very close to the weld.

A thing ive noticed on the first welds, the profile of the weld starts high (less penetration), then as the weld progresses it penetrates more. (see pic2)

Long winded first post i know, just trying to soak in some expert comments.

thanks

martin