Today I got out my Clark mig 135te ,

I haven’t used it for a few years and haven’t really tried it on 2mm thick steel ,not sure or not if I’m getting enough penetration or strong enough welds, also I was getting brown soot,I’ve been using 0.8 wire and a Clark argon co2 mix,and a new real of 0.8 .

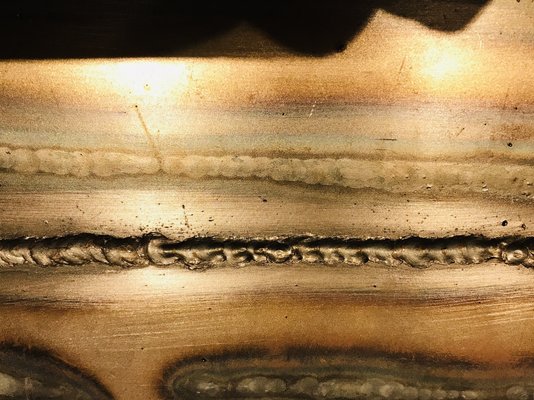

My Practice lap joints ,see pictures.

First attempt after a bit of practice and setting up .

Back of first attempt.

I was getting soot with all attempts.

Last attempt.

Back of last attempt , Is this enough penetration?

Hints and tips welcome thanks .

I haven’t used it for a few years and haven’t really tried it on 2mm thick steel ,not sure or not if I’m getting enough penetration or strong enough welds, also I was getting brown soot,I’ve been using 0.8 wire and a Clark argon co2 mix,and a new real of 0.8 .

My Practice lap joints ,see pictures.

First attempt after a bit of practice and setting up .

Back of first attempt.

I was getting soot with all attempts.

Last attempt.

Back of last attempt , Is this enough penetration?

Hints and tips welcome thanks .