MattF

Forum Supporter

- Messages

- 18,443

- Location

- South Yorkshire

I add washing soda to the water.

This sort of thing, couple of quid in the supermarket.

Exact same thing I've used.

I add washing soda to the water.

This sort of thing, couple of quid in the supermarket.

The thick solid copper wire from swa cable is great for suspending objects.

This was a decent WWII bit for a brace. Left for a few weeks. It certainly did a good job of removing what I assume is case hardening.In my experience of both methods, electrolysis is gentler on the piece, (if done subtly), & I've never had problems with it affecting the surface appearance.

Citric, even though it supposedly doesn't touch good metal, does occasionally, (in my experience. Others experience & opinions may differ), etch/alter surface appearance.

Hence why my personal preference is the former. I always achieve the result I expect.

Plus, there are other points such as you could leave the part in the vat for weeks on end, without issues. I'm sure I'm not the only one on here who has forgotten they'd left a part in citric acid, & found a crusty mess, several weeks later.

Some folk use caustic soda instead but it will not help with rust removal, it's the flow of electricity that does that.Exact same thing I've used.

Or polish with bee's wax.

Some folk use caustic soda instead but it will not help with rust removal, it's the flow of electricity that does that.

But it does mean that you are working with a dangerous chemical and not easy to dispose of.

Local welding supplier calls it viciously applied tax.I hope you have notified the relevant authorities about all this!

.

.

.

.

You are going to have to get vat registered now.

That current seems very low. I've only tried this once, on a seized vice, but I think I had something closer to 2A. But I like more action!Nope. A variable bench psu. That way you can control voltage, limit max current etc. It's a process best done steadily, rather than simply letting it draw as much current as it can.

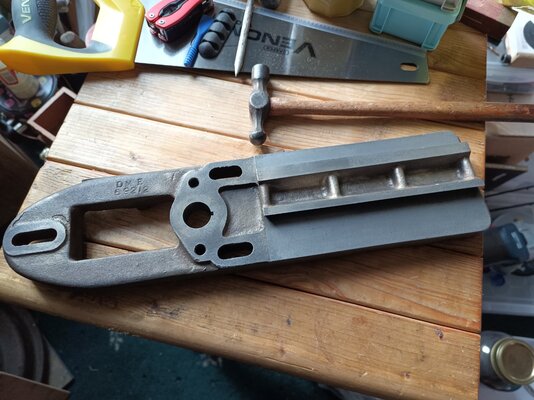

Taken the handle out of the vat & given it a quick scrub.

View attachment 491348

The remaining black is where the surface has pitted. That, I'll just leave as is. It's of no detriment to the piece. Removing that would purely be for cosmetics. Compared to the before, a notable difference.

View attachment 491349

That's just over 24 hours at 12V, & approx. 150mA.

Try it - it’s surprisingly easy, and it’s surprisingly effective.Following this thread with interest - never had a go at this.

Try it - it’s surprisingly easy, and it’s surprisingly effective.

It REALLY works!

Following this thread with interest - never had a go at this.

I've read, but never confirmed myself, that high-carbon steels don't like electrolysis much - particularly springs, which can become brittle. Maybe someone can either confirm or dismiss this, but it might explain why the business end of your screwdriver bit has turned out like that.This was a decent WWII bit for a brace. Left for a few weeks. It certainly did a good job of removing what I assume is case hardening.

View attachment 491498View attachment 491499

I've read, but never confirmed myself, that high-carbon steels don't like electrolysis much - particularly springs, which can become brittle.