You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Edwards jenny (swager)

- Thread starter lotus 30

- Start date

I left this thread unread because a cursory glance was not enough to draw me in...but... keep it it chaps, I was thinking about making a swager, not swagger, ages ago.

Loving this.

since I've done some more work on mine today, it would be rude not to take it apart and show how simple they really are.

this is as I got it nearly 2 and a half years ago

so here's what the cheap ones are based arround, a metal plate with a post welded on and a couple of slots and 3 holes,but the plates do vary in thickness, the metz ones are about 8 mm thick so bend, I think I read somewhere that the ones from stakesky are about 14mm thick

then there are 4 supports that the main shafts run in, the shaft has a collar and gear on one end to keep it in position. if I knew how simple they were I'd have made my own as it seems that most the rollers you get with them you'll never use.

anyway back to the alterations,

the adjustment for the depth of the bead is a bit basic, its just a bolt that pushes one of the shaft supports. I ended up using the bolt head against the shaft support, and using a 100 hand wheel on the other end of the bolt. this allowed me hold the bolt head with a metal plate so that it would lift the support as well as pushing it down.

the metal plate was strengthened (reduce flexing), by having some 50mm box section on the back

I decided to use a double reduction chain/sprocket assembly to reduce the motor speed, consisiting of a supporting plate to mount the spindle for the double sprocket (the larger plate sprocket was bored out and loctited to the pinion sprocket which was bored out and fitted with oilite bearings). the other sprockets were bored out to fit the motor and shaft of the bead roller. the mounting holes in the supporting plate were slotted to allow for adjustment of the chains.

the support plate was mig welded to the main plate (and a supporting web was later welded on afterwards as the 5mm plate was flexing

and the final assembly, off load it works at 10.5 rpm, and draws 3.5 amps from a 13.8v supply, and when doing some 1/2" beads in 1.0mm steel, it drew 6.5 amps, so it looks like I've been lucky and have got something that will do what I want.

and me trying it out on a piece of scrap metal, (it was already domed before I tried to run a bead on it).

all I need to do now is wire up the electrics properly in suitable enclosures and make some suitable rollers

Hi Optima 21

Love what you've done with the bead roller, I agree with your comments about how simple they are and making your own, which is what I (and probably a few others) would like to do, as every one you read about seems to have been upgraded.

To this end is there any chance of posting up some dimensions as a starting point for us to copy, length and diameter of shafts, spigots, gears and frame would be good.

I also spotted this thread about motorising a bead roller and particularly like Wendelspanswick's solution.

http://www.mig-welding.co.uk/forum/threads/motorised-bead-roller-help.40925/page-2

Coincidentally I've just bought a Metz shrinker stretcher, not the best quality but perfectly adequate for the money (£92 inc postage)

Best regards

Love what you've done with the bead roller, I agree with your comments about how simple they are and making your own, which is what I (and probably a few others) would like to do, as every one you read about seems to have been upgraded.

To this end is there any chance of posting up some dimensions as a starting point for us to copy, length and diameter of shafts, spigots, gears and frame would be good.

I also spotted this thread about motorising a bead roller and particularly like Wendelspanswick's solution.

http://www.mig-welding.co.uk/forum/threads/motorised-bead-roller-help.40925/page-2

Coincidentally I've just bought a Metz shrinker stretcher, not the best quality but perfectly adequate for the money (£92 inc postage)

Best regards

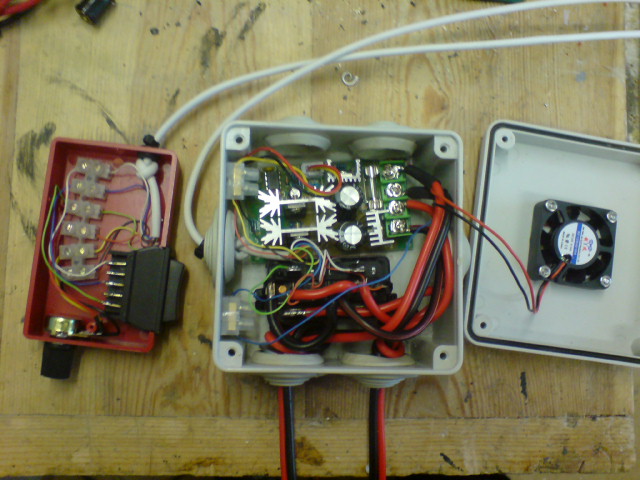

I'll get some dimensions in the near future, I've just boxed up the wiring today, still gone for the hand control with forward/reverse switch and speed control. I ended up using chock block connections in case I end up using a foot control later. the box with the speed controller and relays has been fitted with a tiny fan too. I was going to get a project box, but ended up using a 100 x 100 x 60 enclosure

http://www.toolstation.com/shop/p94184

next on the list is to make some suitable rollers, might be easier if I had a lathe as the size of Lotus 30's, but I'll get it done in the next few weeks.

speaking of Metz shrinker/stretchers, I ordered some metal to make a deep throat version, as they seem to work the same way, but have a different body, so my idea is to fabricate a new frame and and use the original moving parts.

http://www.toolstation.com/shop/p94184

next on the list is to make some suitable rollers, might be easier if I had a lathe as the size of Lotus 30's, but I'll get it done in the next few weeks.

speaking of Metz shrinker/stretchers, I ordered some metal to make a deep throat version, as they seem to work the same way, but have a different body, so my idea is to fabricate a new frame and and use the original moving parts.

Wallace

Member

- Messages

- 7,809

- Location

- Staines, Middlesex, England.

since I've done some more work on mine today, it would be rude not to take it apart and show how simple they really are.

this is as I got it nearly 2 and a half years ago

That's about when I bought mine!

lotus 30

classic car enthusiast mostly lotus

- Messages

- 725

- Location

- caldicot south wales uk

Just used mine and put through 2.5 mil ali to make my water pans all worked fine glad i put a foot control on it though as the ends are radius and i had to stop and start quite often to keep the job against the guide, It has given the part i made not sit flat got to sort that one yet.

mike 109444

Member

- Messages

- 4,865

I think what can happen is while you are concentrating on following a line AT THE ROLLER you may not notice that the out feeding metal (what you have rolled) is drooping and your rolling is now reenforcing the tendency to bend down. Think I have seen a feed in and feed out table/guide attached before now to try and stop this.Just used mine and put through 2.5 mil ali to make my water pans all worked fine glad i put a foot control on it though as the ends are radius and i had to stop and start quite often to keep the job against the guide, It has given the part i made not sit flat got to sort that one yet.

lotus 30

classic car enthusiast mostly lotus

- Messages

- 725

- Location

- caldicot south wales uk

Called in to my mates who is fred in the shed thread for some advice some times it is wiser to ask than go blindly on i may have to press the ends first on the fly press but i will try adding a roller first what i have made will work as there is 200solid rivets per side they will pull it down when i clamp it to a big flat plate it pulls down ok i have then applied heat to try and get it to relax in a flat plain.

at fat franky

yeah Wendelspanwick's bead roller was one that I saw on the net and suggested it was within my abilities, and was workable, the comments on speeds on that thread were also valuable.

so here are some rough dimensions, you'll may need to look at my earlier photos

base 560mm x 200mm x 10mm, long slot is 430mm x 20mm, the centres for the 4 holes for the shaft supports are on 52mm x 515mm, one is turned into a slot for adjusting the rollers

shaft supports (4 off) are 25mm x 40mm x 50mm tall, and the shast runs in a 25mm hole 30mm from the edge of the 40 x 50mm face. these supports are threaded M12 on the 40mm x 25mm face to be bolted to the base.

the shafts are 25mm dia, one is 670mm long (longer for the handle /power drive) and the other is 625mm long. both shafts are reduced to 22 mm at one end for 35mm for the rollers.

you'll also need 2 off 25mm collars and a couple of gears. they are 20 teeth each and aprox 54.5mm diameter.

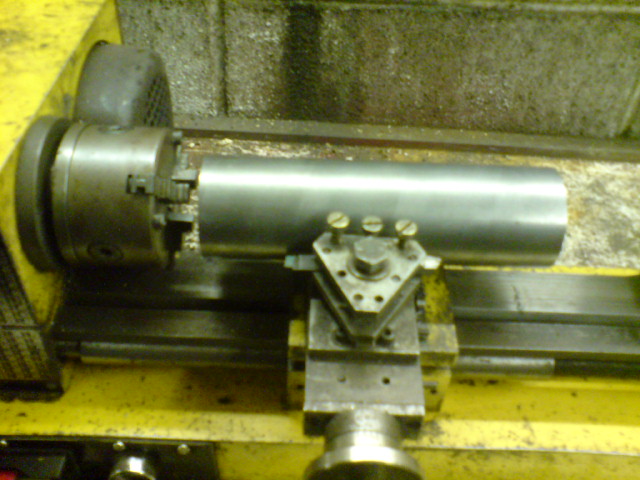

it might be a while before I make the rollers though as I've decided I need to modify my lathe first, but here is a pic of the lathe and the bar to make the rollers from.

To this end is there any chance of posting up some dimensions as a starting point for us to copy, length and diameter of shafts, spigots, gears and frame would be good.

I also spotted this thread about motorising a bead roller and particularly like Wendelspanswick's solution.

Best regards

yeah Wendelspanwick's bead roller was one that I saw on the net and suggested it was within my abilities, and was workable, the comments on speeds on that thread were also valuable.

so here are some rough dimensions, you'll may need to look at my earlier photos

base 560mm x 200mm x 10mm, long slot is 430mm x 20mm, the centres for the 4 holes for the shaft supports are on 52mm x 515mm, one is turned into a slot for adjusting the rollers

shaft supports (4 off) are 25mm x 40mm x 50mm tall, and the shast runs in a 25mm hole 30mm from the edge of the 40 x 50mm face. these supports are threaded M12 on the 40mm x 25mm face to be bolted to the base.

the shafts are 25mm dia, one is 670mm long (longer for the handle /power drive) and the other is 625mm long. both shafts are reduced to 22 mm at one end for 35mm for the rollers.

you'll also need 2 off 25mm collars and a couple of gears. they are 20 teeth each and aprox 54.5mm diameter.

it might be a while before I make the rollers though as I've decided I need to modify my lathe first, but here is a pic of the lathe and the bar to make the rollers from.

mike 109444

Member

- Messages

- 4,865

Don't think he nees any of that cos he is making that length of bar float in thin air........Do you have external jaws for the chuck? Or you could turn between centres with a driving dog welded to the job.

Well I can't see what's holding it there

lotus 30

classic car enthusiast mostly lotus

- Messages

- 725

- Location

- caldicot south wales uk

Just thought i would try my video setting on the camera never used it before this shows the powered up jenny take no notice of the film as i had to hold camera and turn the material and operate foot pedal im a bloke so don't do multi tasking LOL. I will have to modify or make new rollers as it is putting to many marks in the job but the form is ok o

ther than the ends curve up and it needs to remain flat for the application it is for so i am thinking about the MK2

ther than the ends curve up and it needs to remain flat for the application it is for so i am thinking about the MK2

Having said that i have made life hard for myself it is 2.5 mm aircraft ali and is 50 years old but annealed before forming. Having a day off so i thought i would try filming the jenny.

Failed to put up the film i will try again

Having said that i have made life hard for myself it is 2.5 mm aircraft ali and is 50 years old but annealed before forming. Having a day off so i thought i would try filming the jenny.

Failed to put up the film i will try again

lotus 30

classic car enthusiast mostly lotus

- Messages

- 725

- Location

- caldicot south wales uk

failed sorry https://www.youtube.com/channel/UCIv_U4UFf4Eu7nhLksk4ddQ

failed sorry https://www.youtube.com/channel/UCIv_U4UFf4Eu7nhLksk4ddQthink i got it LOL i am a blacksmith with this machine

taycat

Member

- Messages

- 394

- Location

- yorks uk

That's about when I bought mine!

looks like one dad bought years ago.

he swapped handle for bike wheel though.

was lent to someone who eventually returned rusted to hell and the platic box full of rollers was full of water.

project for next half term is striiping and sorting it.

remember when i was about 7 helping him make floor pans for daimler coupe with it.

lost track of other bits we made.

mike 109444

Member

- Messages

- 4,865

Think you motor is running to fast!!!... Ok on the straight but speed control needed on the curvefailed sorry https://www.youtube.com/channel/UCIv_U4UFf4Eu7nhLksk4ddQ

think i got it LOL i am a blacksmith with this machine

lotus 30

classic car enthusiast mostly lotus

- Messages

- 725

- Location

- caldicot south wales uk

Yes its ok as i have a foot pedal so it stops but with two hands on it it's ok i was trying to hold the camera and did not have any pressure on the work piece when it's under load it does slow down if i have a problem i can put it on 14v to slow it down without loosing torque. sorry about the quality of the video as i have never done that before big learning curve.

cardiffrob

Member

- Messages

- 1,665

- Location

- Wales, Llantwit Major.

For a foot pedal, how about one from an old Singer sewing machine?

I collected a Vedette BMC engine from Chepstow over the weekend and it has an epicyclic gearbox (think that is what it is called) with a bunch of circa 1.5 inch dia gears in it that look ideal apart from the smallish bore to them. I only use 1.2 or 1.5mm 1050 ali so shouldn't need to be too beefy.

I collected a Vedette BMC engine from Chepstow over the weekend and it has an epicyclic gearbox (think that is what it is called) with a bunch of circa 1.5 inch dia gears in it that look ideal apart from the smallish bore to them. I only use 1.2 or 1.5mm 1050 ali so shouldn't need to be too beefy.