I had been thinking of a getting a metal cutting bandsaw for a while for cutting bar metal for a while. when I got up on the morning after the Europe referendum, the first thing I did after making a cuppa was to order one, due to the doom and gloom about changes in currency exchange rates. This was shipped from Germany and priced in pounds sterling, so I ordered it before the prices went up, and they are now £40 more than I paid. (was £192.48)

http://www.ebay.co.uk/itm/371564826151

my first impression wasn't too good as I broke it trying to cut some wood like this (125mm long which is the maximum for this machine)

The bandsaw has an electronic speed control and I was using it on the fastest setting, and when I fitted the plug I used a 5 amp fuse as I didn't have any 3 amp fuses. After about 10 minutes use (not continious) it stopped working. As this was imported, I took the attitude that warranties arn't worth the paper they are written on and had a look to see what had happened. On the main circuit board there are a couple 6 amp diodes that had blown but had shorted rather than going open circuit. there is also a 4 amp resetable circuit breaker, that didnt go open circuit, but shorted out too. both of these items were replaced and and its been fine since, but I only use it on the slowest speed now.

there are some very similar looking machines about but are much more expensive, but have no idea what the diffrences are between them.

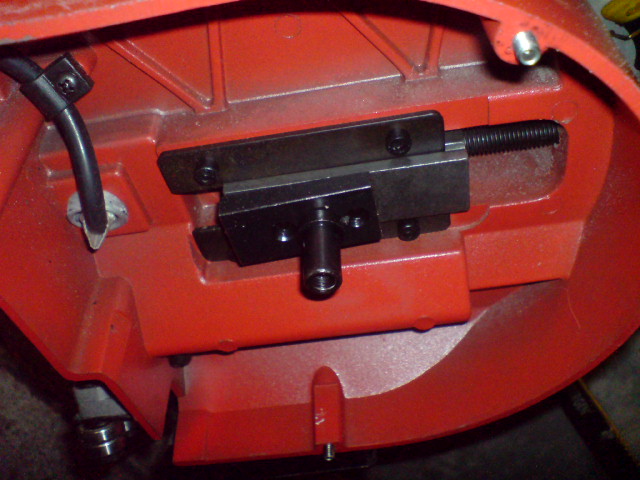

this is the mechanism for adjusting the wheel tension, there are no adjustments for alignment though

the blade guide by the driven wheel needed a bit of adjustment to run true(run vertically), the other one is non adjustable. the pivots that the bearings run in that support the blade alos needed adjusting to remove slop between the bearings and the blade.but this is easy to do as the pivots are eccentric so just need turning to do this. (don't think this is mentioned in the instructions though)

the screws that hold the belt cover in place have now been replaced with studs and wingnuts as is easier than trying to use a screwdriver.

the bandsaw can cut angles up to 60 degrees,and there is an adjustable stop so its easy enough to change back to cutting at right angles on a bar.

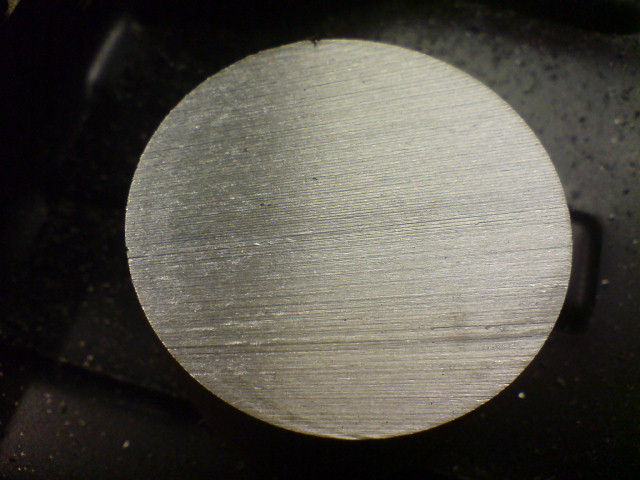

I've finally got round to cutting some metal with it now during the last week. yesterday I was cutting 60mm bar, and it does cut pretty square now

and the finish of the cut using the standard blade

I dont have space for a full sized bandsaw so mine lives here and its about you need a space about 75cm long x 45cm deep x 45cm high to keep it in.

wish I'd got a bandsaw years ago, its much easier than using a hacksaw for cutting thick bar, its hard to get round to doing a job that will take 30 to 45 minutes to cut by hand, yet a machine can do it in a couple of minutes.

http://www.ebay.co.uk/itm/371564826151

my first impression wasn't too good as I broke it trying to cut some wood like this (125mm long which is the maximum for this machine)

The bandsaw has an electronic speed control and I was using it on the fastest setting, and when I fitted the plug I used a 5 amp fuse as I didn't have any 3 amp fuses. After about 10 minutes use (not continious) it stopped working. As this was imported, I took the attitude that warranties arn't worth the paper they are written on and had a look to see what had happened. On the main circuit board there are a couple 6 amp diodes that had blown but had shorted rather than going open circuit. there is also a 4 amp resetable circuit breaker, that didnt go open circuit, but shorted out too. both of these items were replaced and and its been fine since, but I only use it on the slowest speed now.

there are some very similar looking machines about but are much more expensive, but have no idea what the diffrences are between them.

this is the mechanism for adjusting the wheel tension, there are no adjustments for alignment though

the blade guide by the driven wheel needed a bit of adjustment to run true(run vertically), the other one is non adjustable. the pivots that the bearings run in that support the blade alos needed adjusting to remove slop between the bearings and the blade.but this is easy to do as the pivots are eccentric so just need turning to do this. (don't think this is mentioned in the instructions though)

the screws that hold the belt cover in place have now been replaced with studs and wingnuts as is easier than trying to use a screwdriver.

the bandsaw can cut angles up to 60 degrees,and there is an adjustable stop so its easy enough to change back to cutting at right angles on a bar.

I've finally got round to cutting some metal with it now during the last week. yesterday I was cutting 60mm bar, and it does cut pretty square now

and the finish of the cut using the standard blade

I dont have space for a full sized bandsaw so mine lives here and its about you need a space about 75cm long x 45cm deep x 45cm high to keep it in.

wish I'd got a bandsaw years ago, its much easier than using a hacksaw for cutting thick bar, its hard to get round to doing a job that will take 30 to 45 minutes to cut by hand, yet a machine can do it in a couple of minutes.