I've spent a couple of hours looking at your lathe build .

One thing stands out to me well two things ..both your tool rests are round bar . It's easy to slip off them and poke the wood .

A few weeks ago I was given a lesson by a guy in his 80's ( I'm 75) who has turned wood since he was about 8 yrs old.

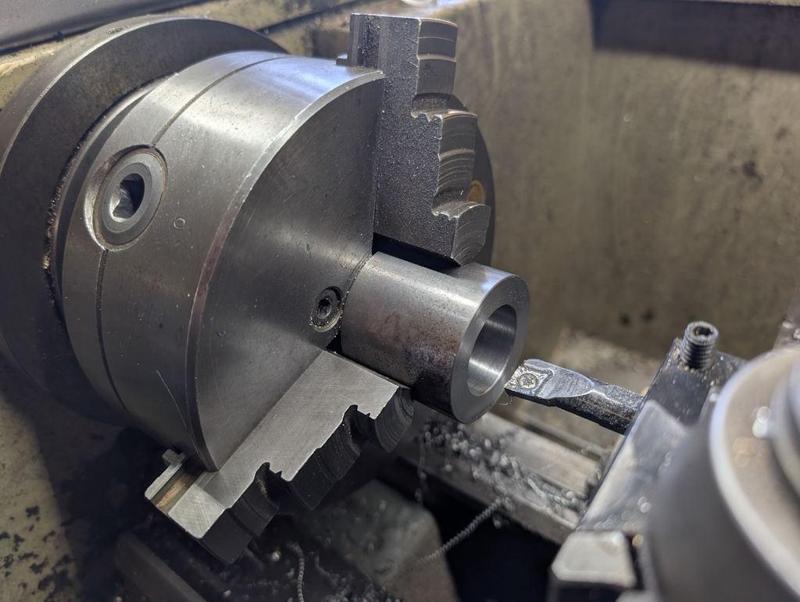

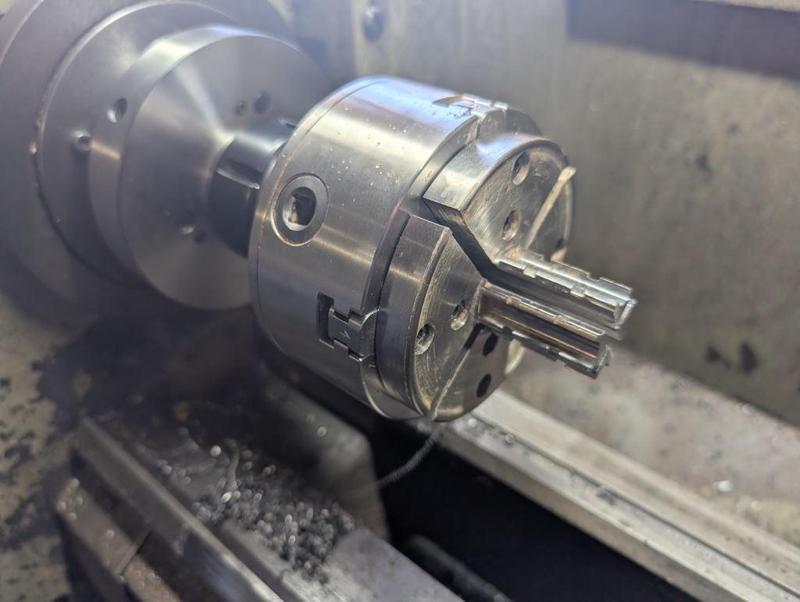

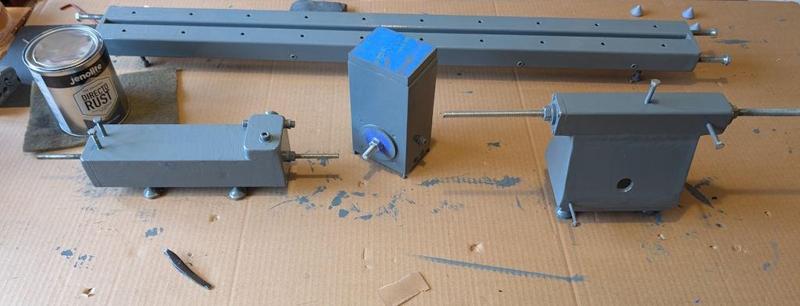

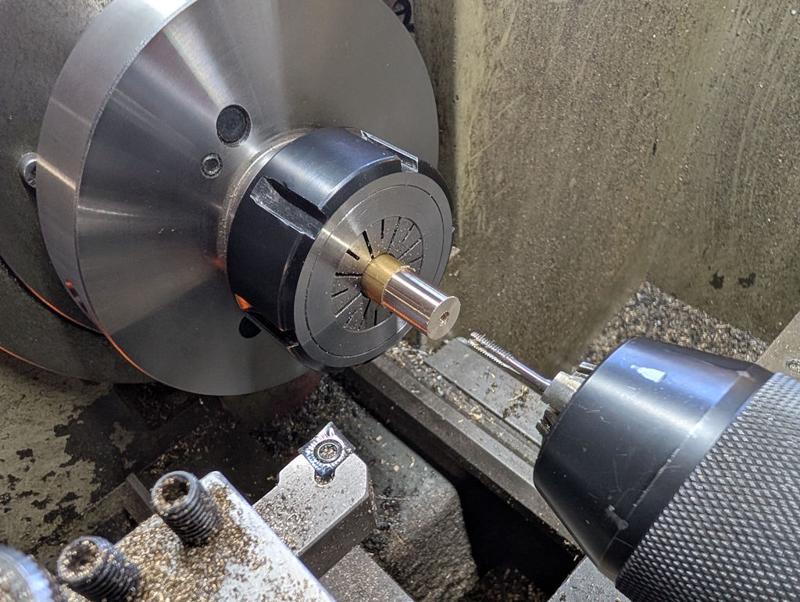

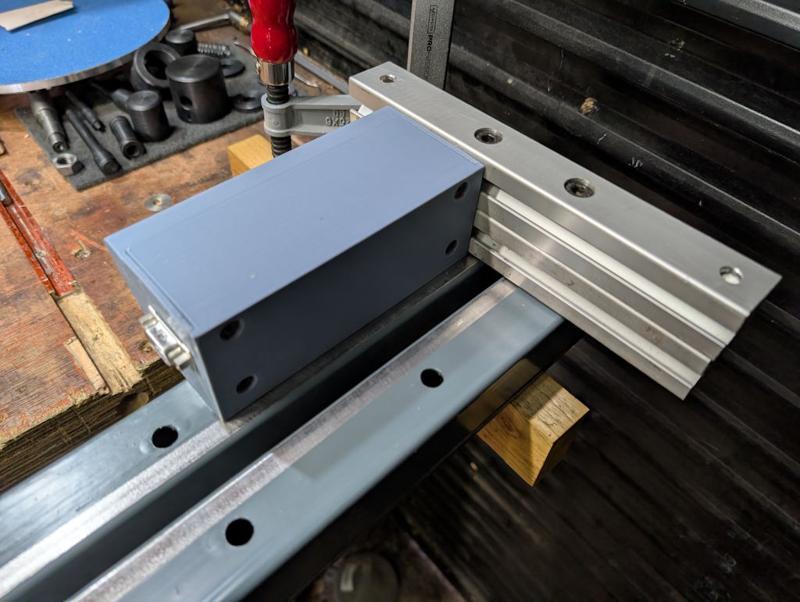

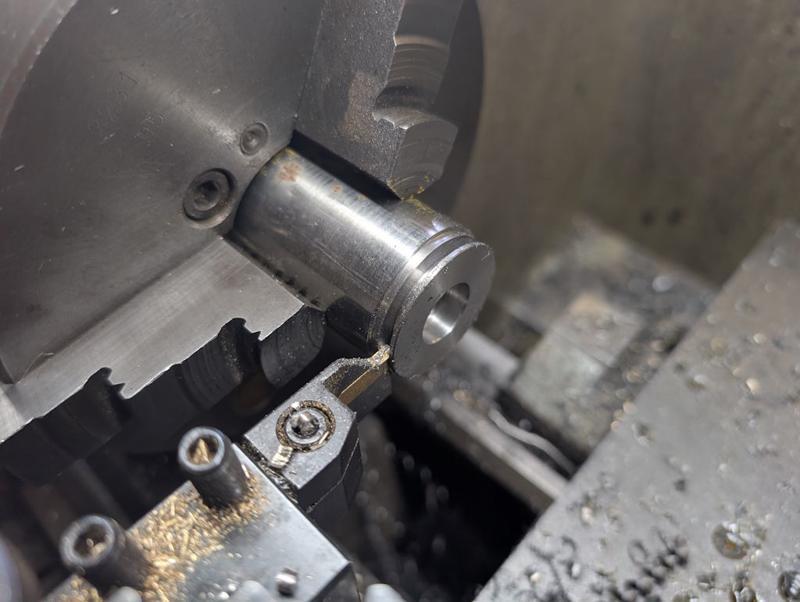

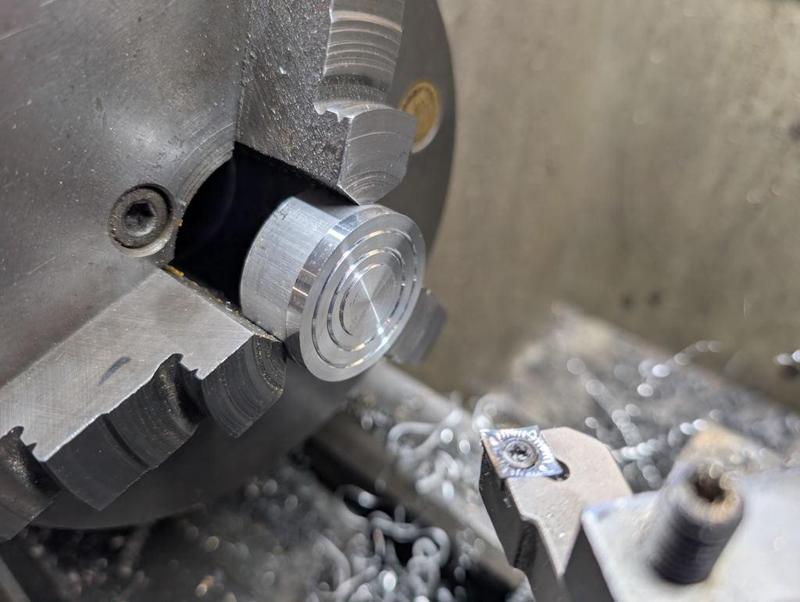

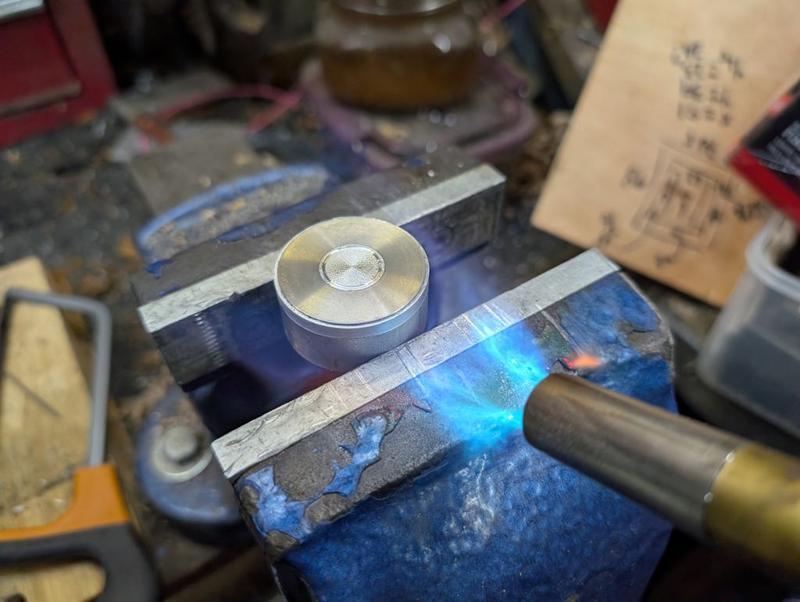

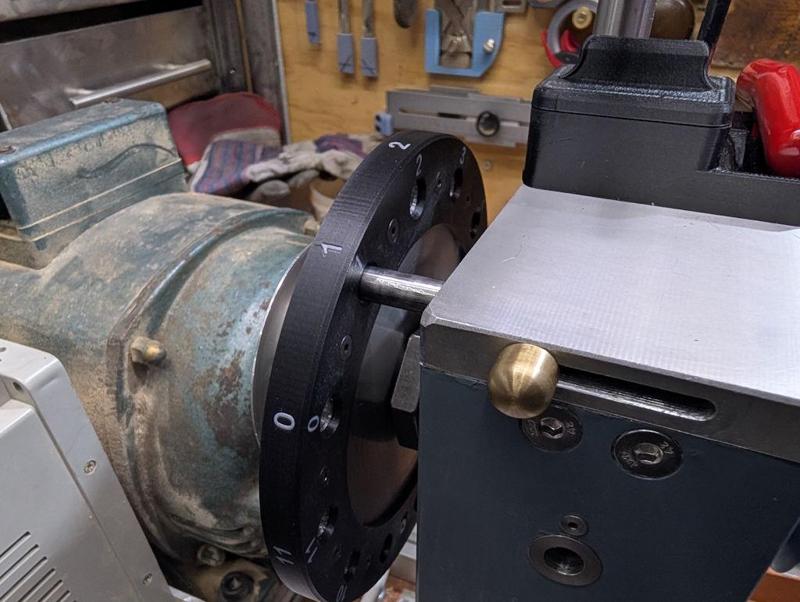

Whilst having a MYFORD ML8 wood lathe it's not able to be set up at present ( awaiting a new mancupboard ) so I used my antique metal lathe that does not have a coolant system . The day before i met him I made a bodged up tool rest out of round stock welded to some angle iron & bolted it across the ways . I turned up some gash soft deal to make some 10 mm plugging . they were as rough as a the proverbial badgers Arrrrz.

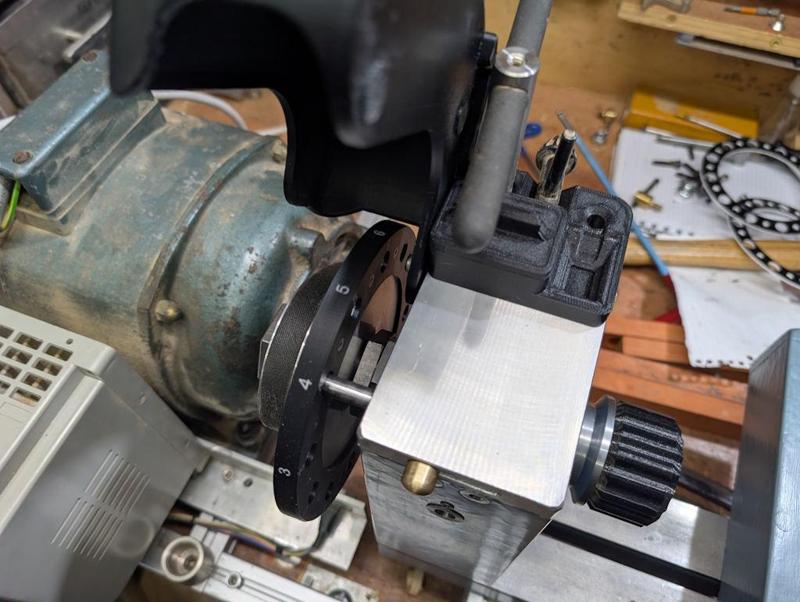

When I gave him the plugging he said , Can I see your lathe " ? In the mancupboard he watched me make some more rough plugging . One thing he said was always place the chisel on the wood with the cutting tip a couple of inches forward and above the center line as it will rattle & bounce if the wood is not round this will stop you digging the chisel in ..

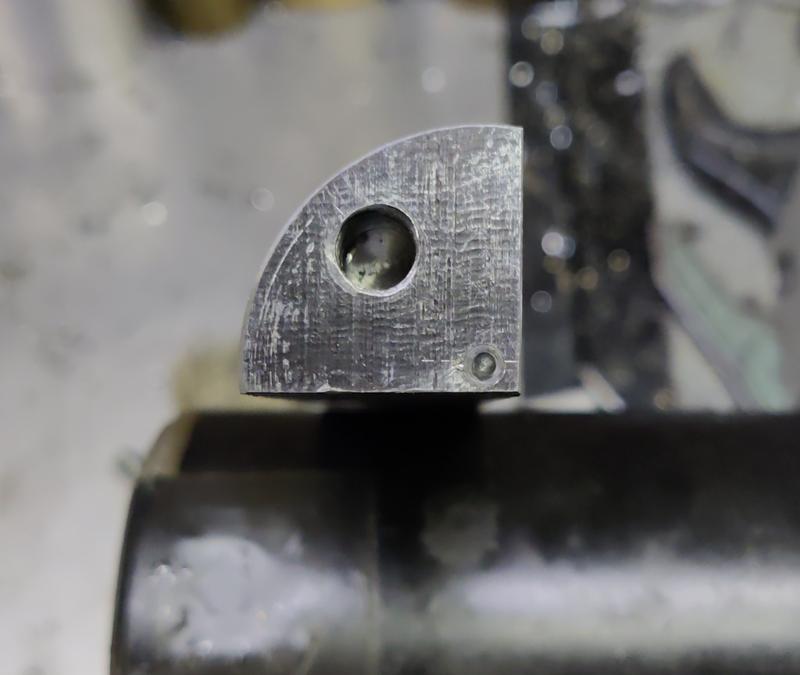

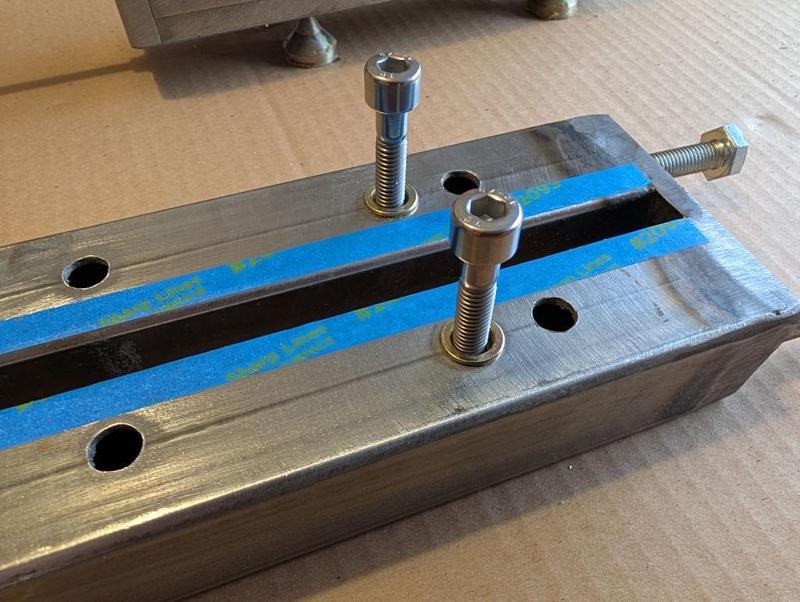

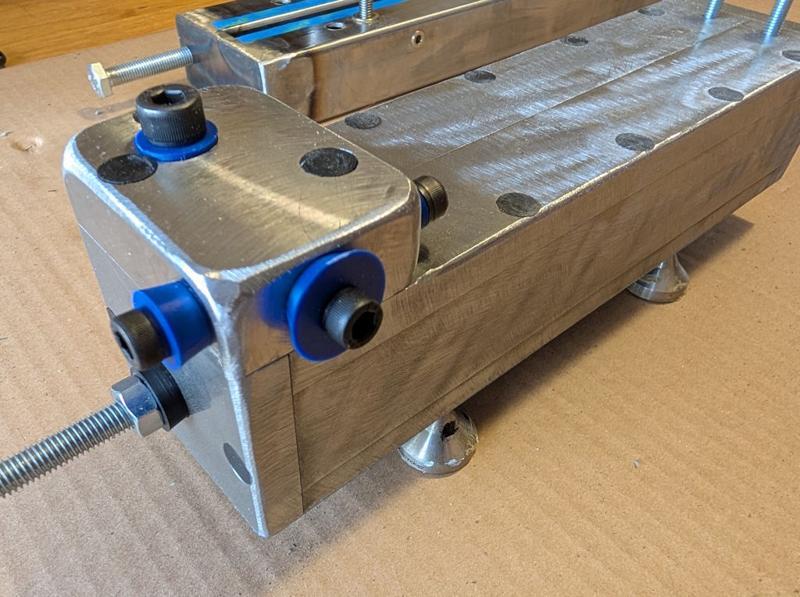

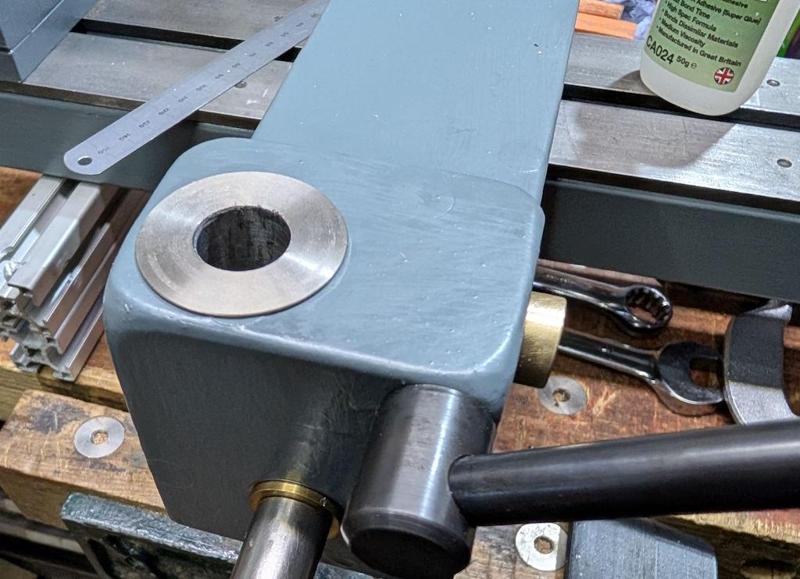

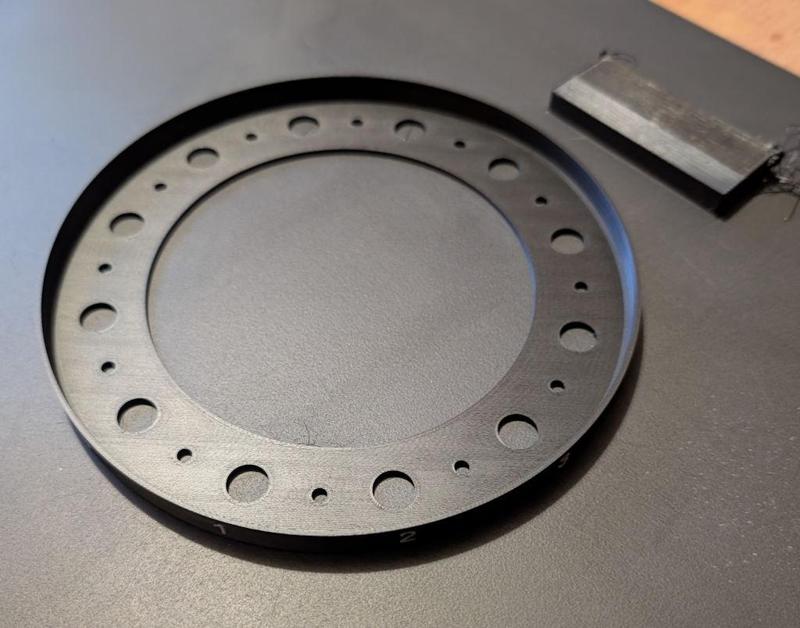

The next was the tool rest he said a round bar will allow you to slip forward with the chisel again causing digging in and variable depths of cut. . MY MYFORD rests are a different shank than the one I made so I ground the round bars off and welded on 1/2 " angle iron pieces . Suddenly things became a lot easier as having a finger against the crook of the angle stopped a lot of unwanted movement .

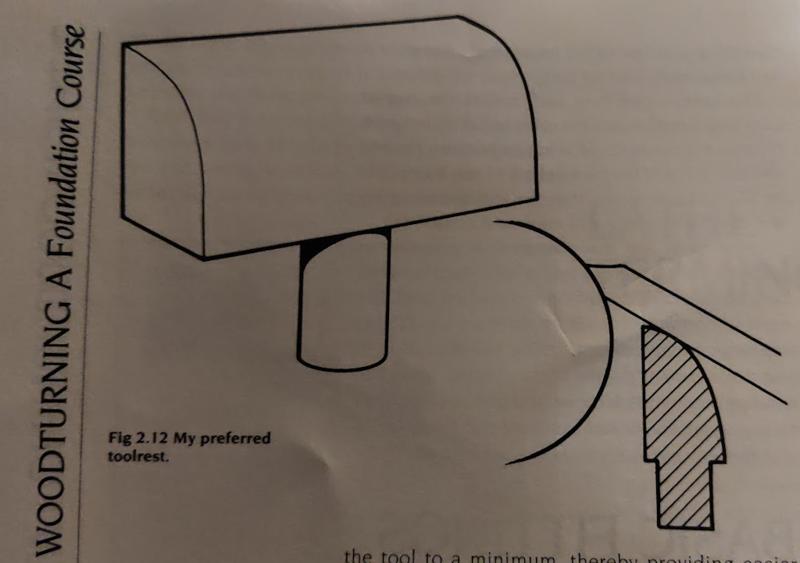

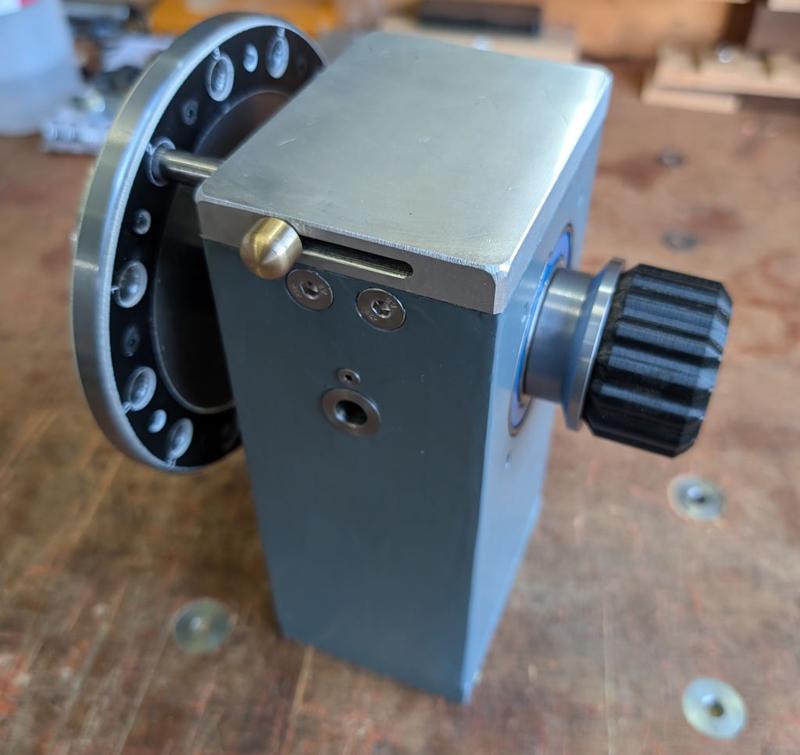

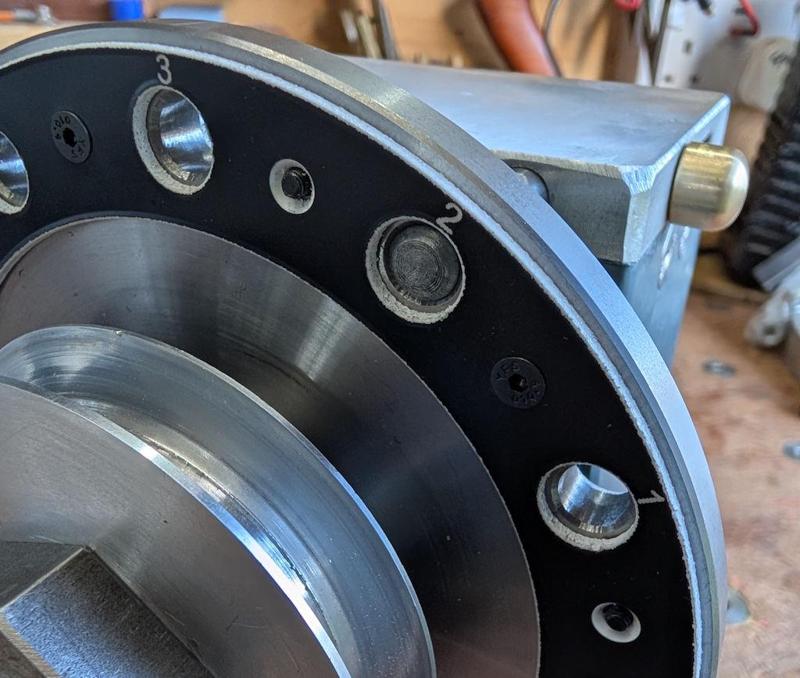

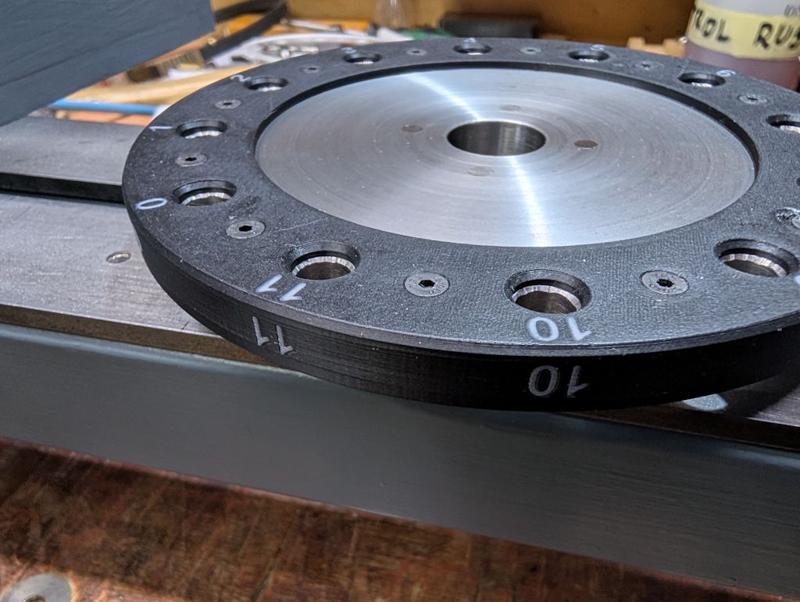

The lathe in the picture with the curved blade facing you on the rest is what he considered to be the best rests ( same as on the MYFORD )

One thing stands out to me well two things ..both your tool rests are round bar . It's easy to slip off them and poke the wood .

A few weeks ago I was given a lesson by a guy in his 80's ( I'm 75) who has turned wood since he was about 8 yrs old.

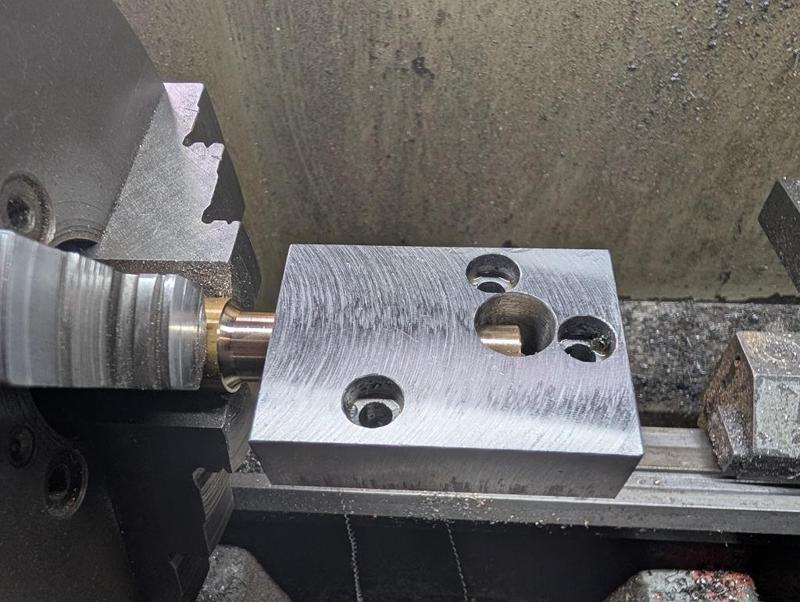

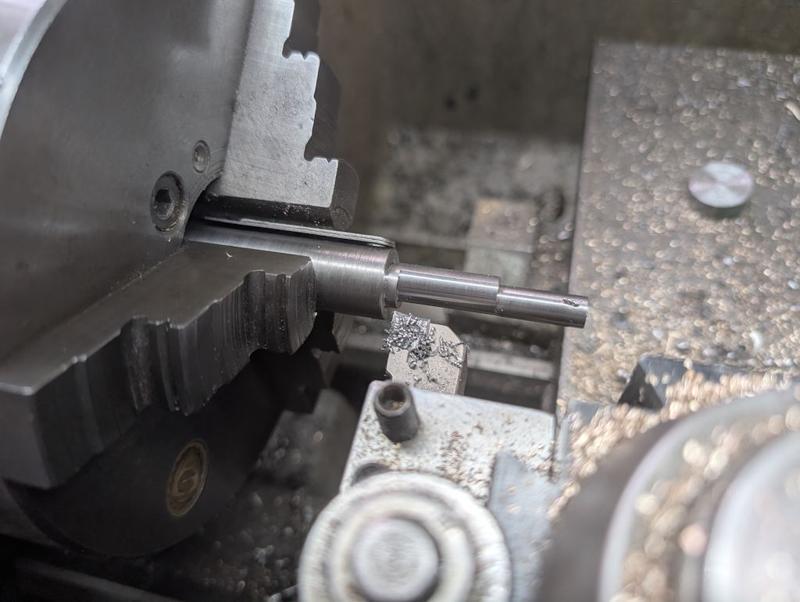

Whilst having a MYFORD ML8 wood lathe it's not able to be set up at present ( awaiting a new mancupboard ) so I used my antique metal lathe that does not have a coolant system . The day before i met him I made a bodged up tool rest out of round stock welded to some angle iron & bolted it across the ways . I turned up some gash soft deal to make some 10 mm plugging . they were as rough as a the proverbial badgers Arrrrz.

When I gave him the plugging he said , Can I see your lathe " ? In the mancupboard he watched me make some more rough plugging . One thing he said was always place the chisel on the wood with the cutting tip a couple of inches forward and above the center line as it will rattle & bounce if the wood is not round this will stop you digging the chisel in ..

The next was the tool rest he said a round bar will allow you to slip forward with the chisel again causing digging in and variable depths of cut. . MY MYFORD rests are a different shank than the one I made so I ground the round bars off and welded on 1/2 " angle iron pieces . Suddenly things became a lot easier as having a finger against the crook of the angle stopped a lot of unwanted movement .

The lathe in the picture with the curved blade facing you on the rest is what he considered to be the best rests ( same as on the MYFORD )