You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY skid steer log splitter attachment (and maybe boom lift)

- Thread starter Bki26

- Start date

Didn't get round to work on it till late afternoon due to unloading the lathe and returning the engine hoist so only managed to finish the welds for the ears and weld in the back supports, despite how clean the metal is there's always the white dust like when welding galvanised but perhaps it's normal for stick since I'm used to tig/mig. Either way it's all solid and now I can work on the push plate/carriage.

Got both bits for the carriage drilled just need to cut it off and weld the push plate on. Next on the list is drilling the 2 plates joining the carriage pieces then it's just welding in the blade and little reinforcement pieces on the ears for it to be done!

Shiny Steve

Member

- Messages

- 352

- Location

- kent

I do love a good log splitter I’m just about to start re building my old beast.

Is this to be used in cab or externally

Is this to be used in cab or externally

It'll be mounted like this and run on the auxiliary hydraulics since I rebuilt and rewired the bricked controller.I do love a good log splitter I’m just about to start re building my old beast.

Is this to be used in cab or externally

Got the plates drilled, took me ages to figure out why everything seemed twisted only to realise the bit of beam I was sitting the lot on has a bulge in the flange lol thankfully it's only an issue when the ram is fully retracted causing a slight binding but small enough to not matter to the ram being 10t.

Blade pieces are cut just gotta grind the bevel in and weld them up, thinking I'll have an easier time cutting the majority of the bevel off with a slitting disc then 40 grit flapper to finish.

Was a cracking sunset too.

Blade pieces are cut just gotta grind the bevel in and weld them up, thinking I'll have an easier time cutting the majority of the bevel off with a slitting disc then 40 grit flapper to finish.

Was a cracking sunset too.

Well the welds came out perfectly today, definitely a combo of bad mask/incorrect amps display/2.5mm instead of 3.2mm rods that caused the initial questionable welds but you can't complain about these ones!

All that's left to do is cut the slots I've marked up and weld in the blade pieces then it's chopping time!

All that's left to do is cut the slots I've marked up and weld in the blade pieces then it's chopping time!

selectedgrub

Member

- Messages

- 3,558

- Location

- New Zealand

Good stuff.

Got the blade pieces welded in before the rain started. Decided to change the design and weld the ends together without the 4mm plate in between, thinking by tapering the thickness the tip will encounter slightly less resistance than the root when splitting and welding the plates together preloaded might help them resist bending and stiffen it all up etc.

Just need to fill the gap then bevel and it's finished!

Just need to fill the gap then bevel and it's finished!

Well those who doubted my welds can marvel in the power of the beast I've created

Absolutely destroys anything I chucked at it including 12"+ and most of the logs split with the engine at idle and barely put load on it even with huge knots.

Its even strong enough to cut/crush 4" against the grain lmao

Also tried the 150kg+ "log" and it managed to split that thing so I can finally move it without throwing my back out.

The only damage was from pushing some long thin logs that bent the channel that makes up the push plate however that's not surprising with several tonnes against 5mm of steel but it actually works better now as gives 2 contact surfaces instead of one large flat one on the logs so they don't slip off

Absolutely destroys anything I chucked at it including 12"+ and most of the logs split with the engine at idle and barely put load on it even with huge knots.

Its even strong enough to cut/crush 4" against the grain lmao

Also tried the 150kg+ "log" and it managed to split that thing so I can finally move it without throwing my back out.

The only damage was from pushing some long thin logs that bent the channel that makes up the push plate however that's not surprising with several tonnes against 5mm of steel but it actually works better now as gives 2 contact surfaces instead of one large flat one on the logs so they don't slip off

Pop one in the post for me then, if it survives that I should start a "hydraulic splitter channel" on YouTube destroying viewer suggestionSee how it copes with a 14 inch dia crowned trunk of seasoned ash .

Sooo I decided to mess around/test the welds... Beam is 2m long and skid steer is ~2t with majority at the rear (you can do a wheelie at walking speed with no bucket it's that back heavy) so I managed to get the rear wheels off the ground doing what you see so I'd estimate easily 1t on the beam.

The result was the cross beam has bent/twisted HOWEVER the welds a few said needed redoing didn't budge at all like I expected and it's only twisted the beam between the C channel hangers/ reinforced cylinder ears area everything else doesn't have a mark on it lol.

I reversed most of the bend by pushing the beam into the ground lifting the front and bouncing via pulsing the hydraulics but I'm not fussed with getting it back exactly since 99% of the time will just be wood splitting and most loads to lift won't be more than 250kg so I'm going to add wire cable between the C channel hangers and end of the beam to reinforce so it'll be fine.

Either way it's nice to know the welds are solid!

The result was the cross beam has bent/twisted HOWEVER the welds a few said needed redoing didn't budge at all like I expected and it's only twisted the beam between the C channel hangers/ reinforced cylinder ears area everything else doesn't have a mark on it lol.

I reversed most of the bend by pushing the beam into the ground lifting the front and bouncing via pulsing the hydraulics but I'm not fussed with getting it back exactly since 99% of the time will just be wood splitting and most loads to lift won't be more than 250kg so I'm going to add wire cable between the C channel hangers and end of the beam to reinforce so it'll be fine.

Either way it's nice to know the welds are solid!

Need I say more

dont pi55 in my pocket and tell me its raining.

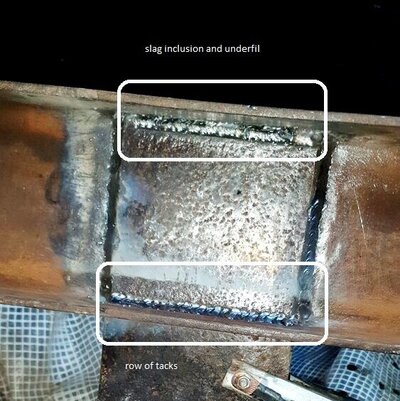

Im not being sly ,,, I think your welding is poor ,,, your design was no better , and its still missing greatly . Ill say it in the open and stand by my opinions and back them with qualifications and experience .

dont pi55 in my pocket and tell me its raining.

Im not being sly ,,, I think your welding is poor ,,, your design was no better , and its still missing greatly . Ill say it in the open and stand by my opinions and back them with qualifications and experience .