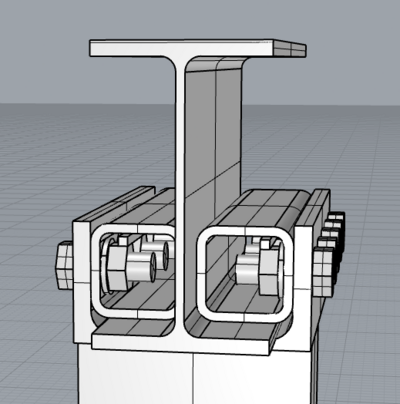

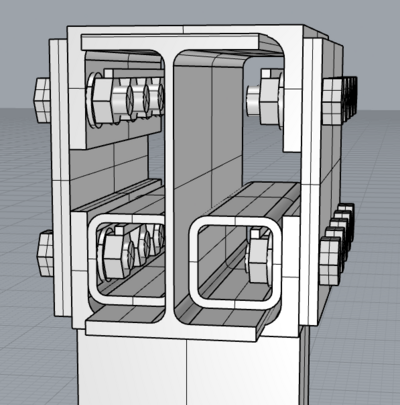

When Fizzy made the bearing mount for his log d splitter screw shaft , Initially, it was a hollow box section. that the self leveling bearing block sat on .Good spot, was planning on doing that so even modeled it in ha View attachment 517788

Due to the immense pressures generated splitting knottes wood the box section started to collapse.

Fizzy's solution was to turn up precise fitting spacers to fully fill the internal space and prevent collapse , he used a powered finger file to remove any internal burrings ( I've used ground to size square bar welded on 3/4 " round before now to clear two feet lengths of hollow box section.

Would it be better to turn up spacers so that with the base plate they fill the void , thread them ,then weld them captive . That way you'll know for sure that you won't get any collapsed box sections