Parm

Respect The Sound System

- Messages

- 18,002

- Location

- Towcester

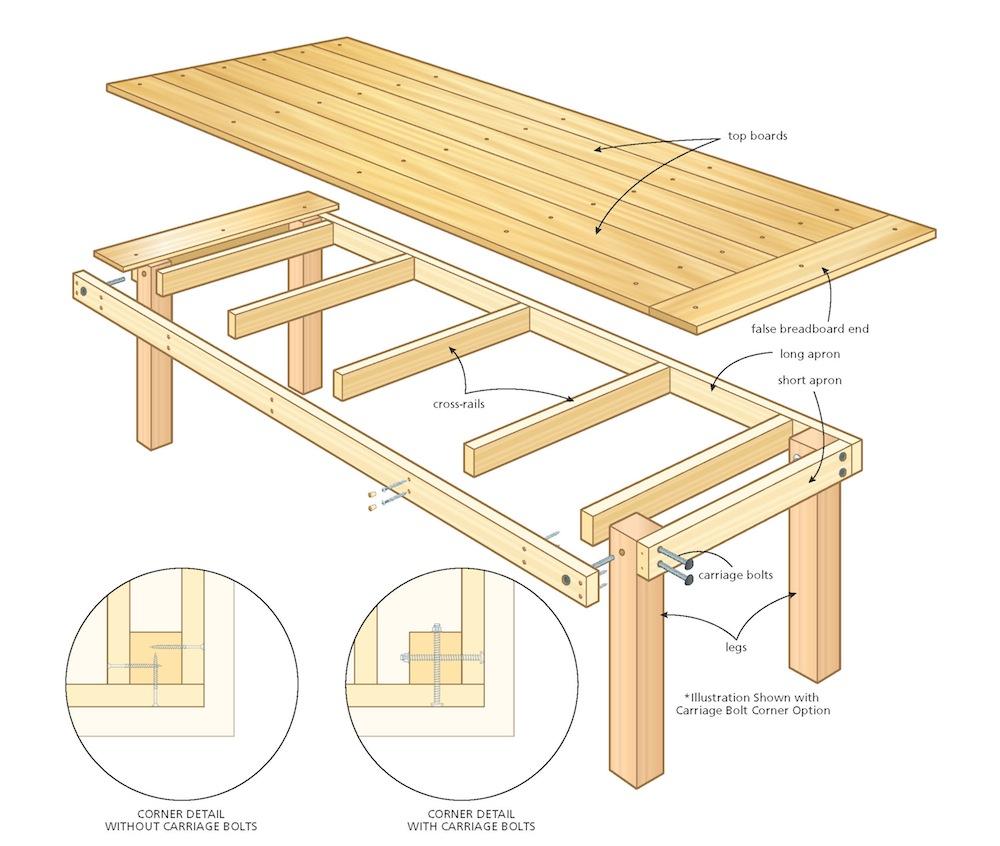

im planning the build of a dining table, similar to the pic below.

Has anyone got any ideas of how I can attach the legs to the inside of the frame. Must be a sturdy fix yet removable so I can get it in and out of the room.

Currently my idea is to have the frame fixed permanently to the top with four removable legs. It will be an all wood construction

Should have said I don’t want to see the fixings from the outside

Has anyone got any ideas of how I can attach the legs to the inside of the frame. Must be a sturdy fix yet removable so I can get it in and out of the room.

Currently my idea is to have the frame fixed permanently to the top with four removable legs. It will be an all wood construction

Should have said I don’t want to see the fixings from the outside

and I would happily stand on it.

and I would happily stand on it.