You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

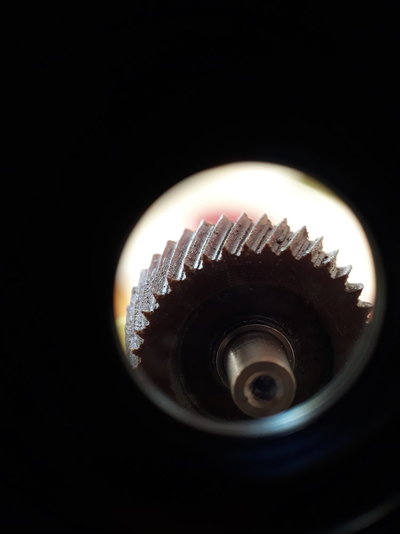

Dead Biax society...

- Thread starter minimutly

- Start date

Too fine, methinksI could 3d print if for you but wont be very strong.

Perhaps 3d print and then use it as a former. Cast it from metal filled epoxy or aluminium.

I now have a resin printer - have you seen how good they are?Too fine, methinks

Detail is incredible!

Seems they are stronger as well. Happy to give it a try for you. Will only cost a fiver or so for each one so doesn't matter if they don't last that long.

Probably take hours to design the part of course but so what - my brother loves tinkering.

daedalusminos

Member

- Messages

- 2,433

- Location

- Norwich

The UV cure resins straight out of the bottle will be too brittle, in fact I doubt you'll get anything that will survive for long. Resins can be mixed to give tailored properties but even that is going to be hit and miss....more miss than hit I would think!

Yes and flog them on Ebay!£350 your not far off a used biax

I would find a gear manufacturer and get a handful made from tufnol

Spark plug

Member

- Messages

- 4,036

- Location

- Durham, England

Agroshield

Member

- Messages

- 6,390

...bad news is $239 plus taxes, plus postage plus taxes etc. Probably £350?

And out of stock...

I think I read on PM somewhere that it is more a case of 'never yet been in stock' rather than out of stock. Maybe the person making them is trying to get enough confirmed orders before he presses the green button.

On a 4 axis cheap Chinese router you could make these for an hour's rate!

With respect, that is utterly misleading. First, you need to obtain a good sample of the gear. Then you need the tools, skill and time to reverse engineer it. Then you need to model it. Then you need a CAM program that knows how to do 4th axis work. Then you need to produce the G-code on that software. Then you need to buy the router and a G-code interpreter with 4th axis capability. Then the tooling. Then the material. Then prepare the material. Then cut your first sample. Then measure it to make sure it matches the sample.

Guess at some costs and times for all of the above. Work out the cost of the first prototype before you have even sold one piece. Assuming it is perfect and needs no second prototype, work out how many and at what price you need to sell them just to break even.

I meant for someone who already had such a machine!I think I read on PM somewhere that it is more a case of 'never yet been in stock' rather than out of stock. Maybe the person making them is trying to get enough confirmed orders before he presses the green button.

With respect, that is utterly misleading. First, you need to obtain a good sample of the gear. Then you need the tools, skill and time to reverse engineer it. Then you need to model it. Then you need a CAM program that knows how to do 4th axis work. Then you need to produce the G-code on that software. Then you need to buy the router and a G-code interpreter with 4th axis capability. Then the tooling. Then the material. Then prepare the material. Then cut your first sample. Then measure it to make sure it matches the sample.

Guess at some costs and times for all of the above. Work out the cost of the first prototype before you have even sold one piece. Assuming it is perfect and needs no second prototype, work out how many and at what price you need to sell them just to break even.

Pete.

Forum Supporter

- Messages

- 15,069

- Location

- Kent, UK

Point is, if I take it off to replace it surely? It doesn't look to be long for this world

Depends if you want to use tha machine. It'll last longer the other way round since the pinion has no clearance at the tip now. Nothing to lose by trying really though I would certainly be putting in on my scanner and takig masurements just in case I was forced to attempt a replacement.