RIP

Kairo

- Messages

- 3,030

- Location

- Netherlands

I've wired up the ECU on my buggy and the engine starts, yepee  Got to say that was quite a challenge, reverse engineering the original loom, and all those sensors and plugs to solder up, but very happy with the result.

Got to say that was quite a challenge, reverse engineering the original loom, and all those sensors and plugs to solder up, but very happy with the result.

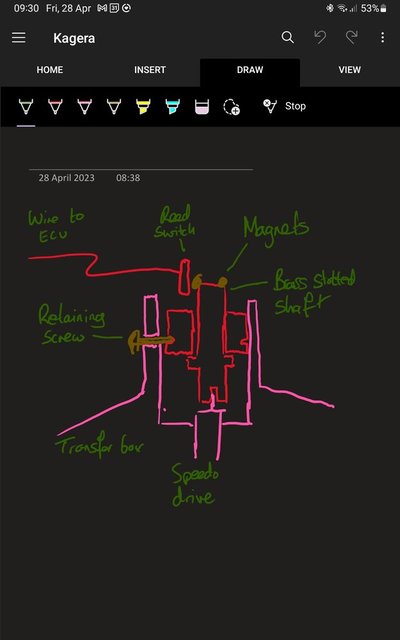

There's still one more ECU sensor to go, and that's the most challenging one, the vehicle speed sensor (VSS). The engine starts without it but won't run well under load. On the donor car there was a magnetic reed switch behind the mechanical speedometer that fed a signal to the ECU. I won't have that.

I'm thinking of making a digital sensor that will spin off the original transfer box mechanical speedo output. I have a lathe and it looks like I can turn a slotted shaft to run inside a cylinder that will fit the transfer box hole.

Question is about lubrication. Will a smear of grease be enough between the shaft and cylinder it will run inside of? I'm guessing it will seeing as mechanical speedo cables use grease.

Also open to any simpler ideas for making this sensor.

The ECU expects 100 Hz at 87 mph, so I have to do some maths, and may need multiple magnets on the shaft.

Got to say that was quite a challenge, reverse engineering the original loom, and all those sensors and plugs to solder up, but very happy with the result.

Got to say that was quite a challenge, reverse engineering the original loom, and all those sensors and plugs to solder up, but very happy with the result.There's still one more ECU sensor to go, and that's the most challenging one, the vehicle speed sensor (VSS). The engine starts without it but won't run well under load. On the donor car there was a magnetic reed switch behind the mechanical speedometer that fed a signal to the ECU. I won't have that.

I'm thinking of making a digital sensor that will spin off the original transfer box mechanical speedo output. I have a lathe and it looks like I can turn a slotted shaft to run inside a cylinder that will fit the transfer box hole.

Question is about lubrication. Will a smear of grease be enough between the shaft and cylinder it will run inside of? I'm guessing it will seeing as mechanical speedo cables use grease.

Also open to any simpler ideas for making this sensor.

The ECU expects 100 Hz at 87 mph, so I have to do some maths, and may need multiple magnets on the shaft.