Willyswelder

New Member

- Messages

- 4

- Location

- Norway

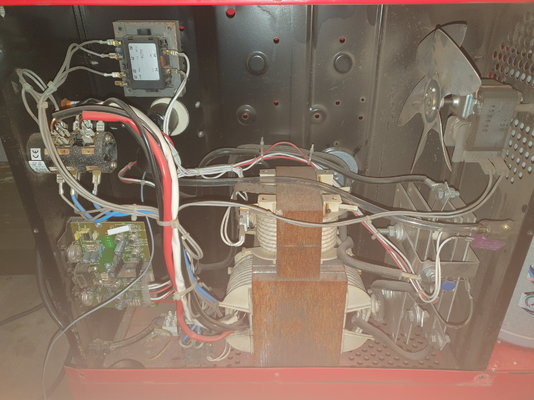

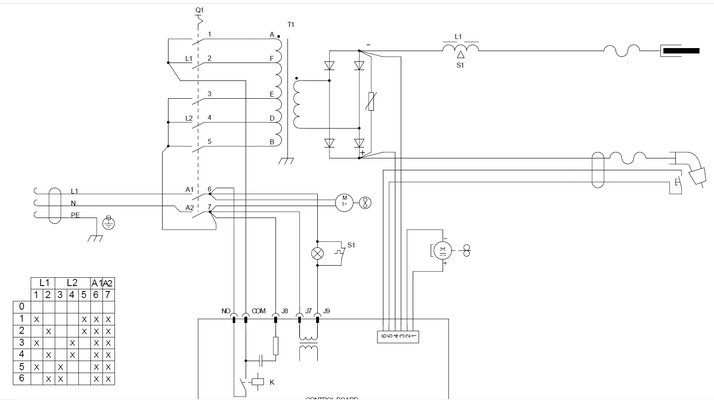

Hello. I just found out that my trusty Telwin 180/2 Turbo needed a new torch. I ordered a Twin 15, which was supposed to fit my machine. The old torch had just one wire. The new had two. One long and one short. The gas line fits, but I can not seem to figure out where to connect the cables. Been trawling the net, with no luck. Hope someone can help. Thanks