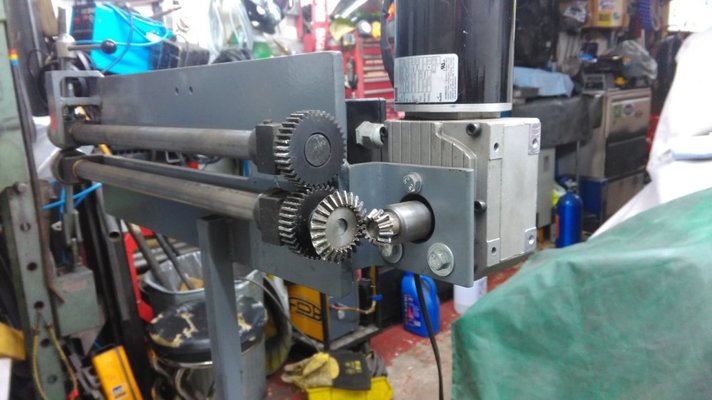

Hi all, as title, planning on converting a niagra hand cranked bead roller to powered for convienience in near future. Small servo or stepper maybe, or a normal small ac motor with a cheap vfd (theyre cheap here for smaller units as tend to be used in domestic heating controls) and reduction box. At the cunning plan formation and aquiring apropriate motor bits stage.

Is it a good idea to make the motor a variable speed for use, or is that overkill with no added gain + a simple on and off motor geared appropriately is just as good? Would soft start add anything to let positions be nudged or something? Reverse a good idea?

What would be a comfortable linear distance traveled per minute by the forming dies to aim for on the gearing?

New to me so no experience to draw on myself, but there's only ever one of me around so I cant get someone to crank it on longer stuff while I feed it in.

Is it a good idea to make the motor a variable speed for use, or is that overkill with no added gain + a simple on and off motor geared appropriately is just as good? Would soft start add anything to let positions be nudged or something? Reverse a good idea?

What would be a comfortable linear distance traveled per minute by the forming dies to aim for on the gearing?

New to me so no experience to draw on myself, but there's only ever one of me around so I cant get someone to crank it on longer stuff while I feed it in.