I think i may have goosed my compressor.

Sorting the place out before starting to strip my bandsaw down for restoration I decided to check the compressor as i noticed it was sounding slightly different. I have it up in the loft out the way, its a 4 year old SGS 14cmf unit with not much use.

When i went up it was covered in oil as was all the roof above it and most of the surround stuff. Now, i think i know what's caused this - me I lost the plastic oil bung so just wedged a bit of aluminium in that happened to fit, this is still firmly wedged in place the oil seems to be coming from under the air intakes somewhere.

I lost the plastic oil bung so just wedged a bit of aluminium in that happened to fit, this is still firmly wedged in place the oil seems to be coming from under the air intakes somewhere.

I know the oil bung is supposed to have a vent to relieve pressure and I'm thinking this pressure has caused the issue.

here's my sticking plaster that i think has caused this !

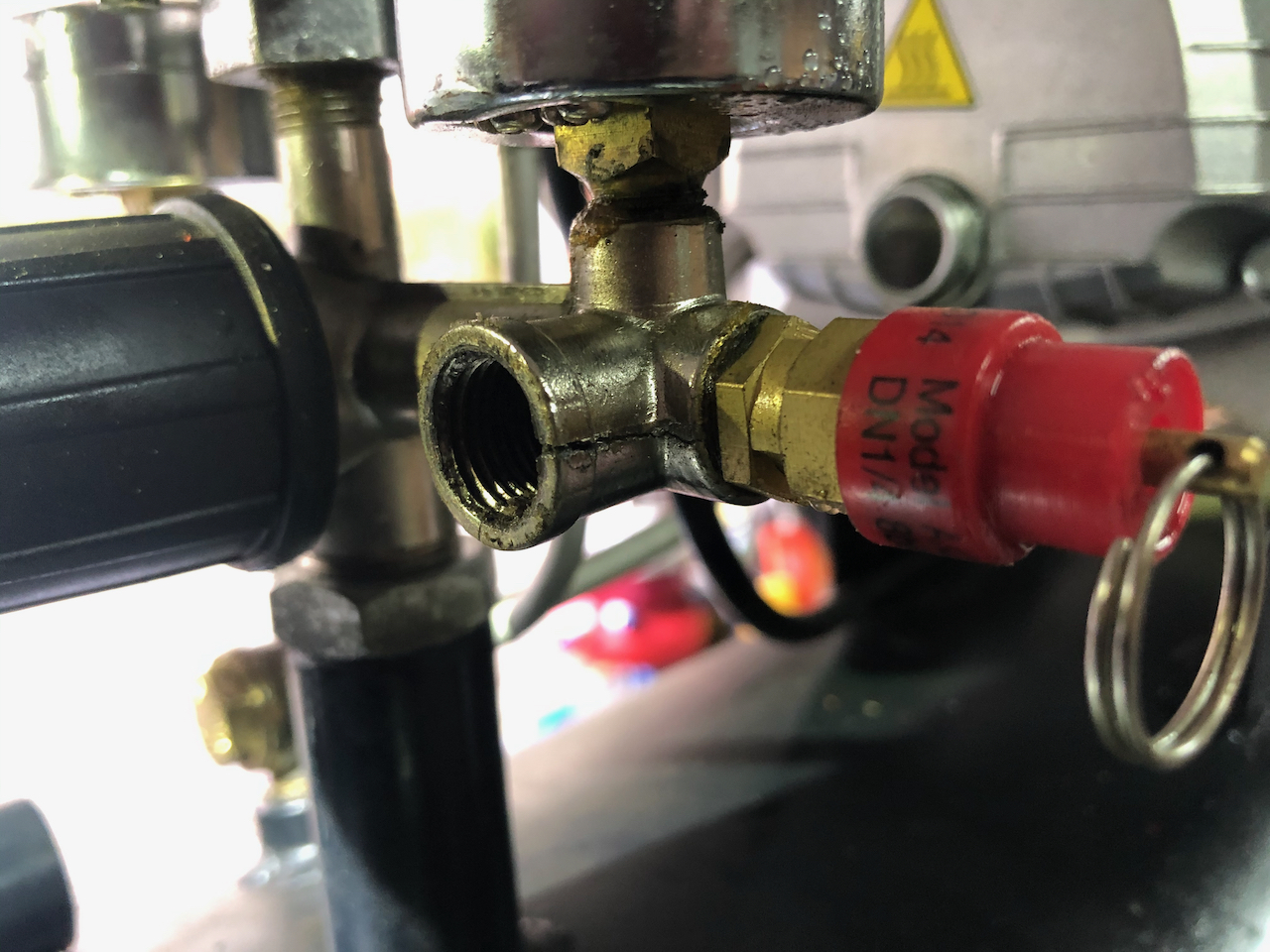

Also noticed another few problems (really not impressed with the quality of this machine) the regulators made of cheese it seems

and connecting pipe flanges are in bits

So before i start replacing the regulator any ideas or thoughts on what damage i have caused internally?

thanks in advance

Sorting the place out before starting to strip my bandsaw down for restoration I decided to check the compressor as i noticed it was sounding slightly different. I have it up in the loft out the way, its a 4 year old SGS 14cmf unit with not much use.

When i went up it was covered in oil as was all the roof above it and most of the surround stuff. Now, i think i know what's caused this - me

I lost the plastic oil bung so just wedged a bit of aluminium in that happened to fit, this is still firmly wedged in place the oil seems to be coming from under the air intakes somewhere.

I lost the plastic oil bung so just wedged a bit of aluminium in that happened to fit, this is still firmly wedged in place the oil seems to be coming from under the air intakes somewhere.I know the oil bung is supposed to have a vent to relieve pressure and I'm thinking this pressure has caused the issue.

here's my sticking plaster that i think has caused this !

Also noticed another few problems (really not impressed with the quality of this machine) the regulators made of cheese it seems

and connecting pipe flanges are in bits

So before i start replacing the regulator any ideas or thoughts on what damage i have caused internally?

thanks in advance