Hi,

Sorry for yet another "what am I doing wrong" thread, but I'm really stumped.

I bought a clarke 90en off ebay a while back, but have only just been able to try it out properly (i.e. on a clean piece of 1mm sheet, not just bits of random scrap)

When I try to weld, all I get is pop-pop-pop and lots of spatter everywhere, and it just makes a complete mess of the workpiece.

I've set the regulator to 10lpm, but tried it on 20 just in case.

I've made sure that I have a good earth, by clamping some thick wire to the piece as well as the cheapo clamp that comes with the 90en.

I don't know if it's the tip that's knackered, the wire feed, liner, or if maybe my mains wiring isn't up to the job.

The wire feed does seem temperamental. Sometimes it's pushing the torch away from the metal (obviously too fast), and if I turn it down only slightly it leaves a trail of tiny globs on the surface and sounds like a machinegun (too slow?) It also sounds like it cuts out when the arc strikes, but that might just be because the arc is so loud. It's perfectly smooth when i'm not welding though.

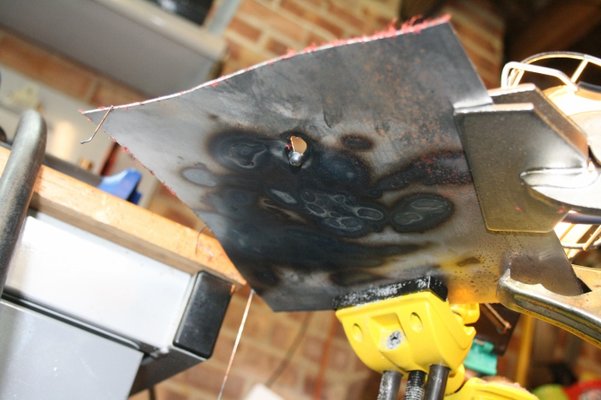

I did manage to get it to arc up properly once, but I could only do it on a high wire speed and maximum power, hence the hole in the metal. <_<

Anyway enough of my rambling, here are some pics of the horrific mess I made

Sorry for yet another "what am I doing wrong" thread, but I'm really stumped.

I bought a clarke 90en off ebay a while back, but have only just been able to try it out properly (i.e. on a clean piece of 1mm sheet, not just bits of random scrap)

When I try to weld, all I get is pop-pop-pop and lots of spatter everywhere, and it just makes a complete mess of the workpiece.

I've set the regulator to 10lpm, but tried it on 20 just in case.

I've made sure that I have a good earth, by clamping some thick wire to the piece as well as the cheapo clamp that comes with the 90en.

I don't know if it's the tip that's knackered, the wire feed, liner, or if maybe my mains wiring isn't up to the job.

The wire feed does seem temperamental. Sometimes it's pushing the torch away from the metal (obviously too fast), and if I turn it down only slightly it leaves a trail of tiny globs on the surface and sounds like a machinegun (too slow?) It also sounds like it cuts out when the arc strikes, but that might just be because the arc is so loud. It's perfectly smooth when i'm not welding though.

I did manage to get it to arc up properly once, but I could only do it on a high wire speed and maximum power, hence the hole in the metal. <_<

Anyway enough of my rambling, here are some pics of the horrific mess I made

at the destruction testing !

at the destruction testing !