- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Machining

- Lathes and other Machining Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Commissioning the big CNC mill

- Thread starter MattH

- Start date

slim_boy_fat

Member

- Messages

- 29,363

- Location

- Scottish Highlands

Now I just need to level it and run a airline to it.

Looks right at home there

Pretty closeLevelled out the mill today using a Moore and Wright 18” machinist level.

Got it bang on:

View attachment 158986 View attachment 158987 View attachment 158988

Richard.

Member

- Messages

- 18,335

- Location

- Cambridgeshire

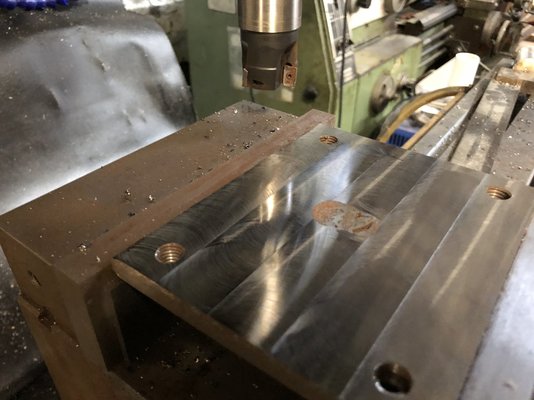

Nice finish Matt.Ran an airline to the mill today and trimmed the head in (not quite perfect yet).

Mounted a vice and faced off an old piece of steel plate that was kicking around.

@Richard. some chips for you.

View attachment 159084 View attachment 159085 View attachment 159086 View attachment 159087 View attachment 159088

Video to follow.

Hood

Member

- Messages

- 17,984

- Location

- Carnoustie, Scotland

I like how you said you connected air up, you didn't tell us it was mouth powered

Looks like quite an easy and comprehensive conversational control that it has

There was a slight pause at the start of the next pass, is that backlash or is it just in exact stop mode or?

Looks like quite an easy and comprehensive conversational control that it has

There was a slight pause at the start of the next pass, is that backlash or is it just in exact stop mode or?

MattH

Member

- Messages

- 4,545

- Location

- Cornwall

Lol, I did put a tee in so I can connect up an airline but didn’t get around to it. The air is for the power drawbar.

There’s no decernable backlash, it has ground ball screws and using the hand wheels and looking at the dro I can’t see any.

With the linear scales the control is fully closed loop.

I presume the way the control creates a facing pass is exact stop. I ran some test pockets and circles the other day and they looked to be CV.

There’s no GCode here though so it’s hard to tell.

There’s no decernable backlash, it has ground ball screws and using the hand wheels and looking at the dro I can’t see any.

With the linear scales the control is fully closed loop.

I presume the way the control creates a facing pass is exact stop. I ran some test pockets and circles the other day and they looked to be CV.

There’s no GCode here though so it’s hard to tell.

MattH

Member

- Messages

- 4,545

- Location

- Cornwall

No, it’s conversational only but you can save the programs.

To be honest it’s a prime candidate for a conversion but the only controller I know of that can close the loop with linear scales is the Kflop which I’m not that keen on (I have one from a few years back).

This machine will probably stay as it is and I will eventually build the small square column mill that I have been planning.

The idea is to finally build my big CNC router after the Xmas rush and use this mill to assist with that.

To be honest it’s a prime candidate for a conversion but the only controller I know of that can close the loop with linear scales is the Kflop which I’m not that keen on (I have one from a few years back).

This machine will probably stay as it is and I will eventually build the small square column mill that I have been planning.

The idea is to finally build my big CNC router after the Xmas rush and use this mill to assist with that.

Hood

Member

- Messages

- 17,984

- Location

- Carnoustie, Scotland

The IP/A should be able to take feedback from scales. They have their own software now but sadly I can't try it out as my IP/A is the previous generation and it needs the FP4, so no idea if it is any good or how they are progressing with it.

There was a slight pause at the start of the next pass, is that backlash or is it just in exact stop mode or?

I presume the way the control creates a facing pass is exact stop. I ran some test pockets and circles the other day and they looked to be CV.

There’s no GCode here though so it’s hard to tell.

Is most likely 'look ahead' with the controller. All controllers have a look ahead where it will try to read the upcoming lines of code to prevent stops in the program while its reading the new information. This is common in a lot of older controllers to see stops like this. It's stopping to read the next lines of information so it knows what to do next.

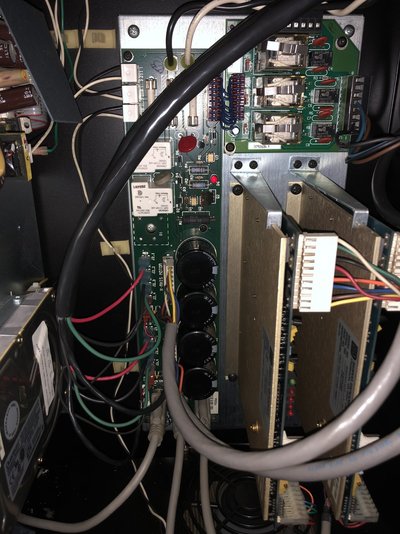

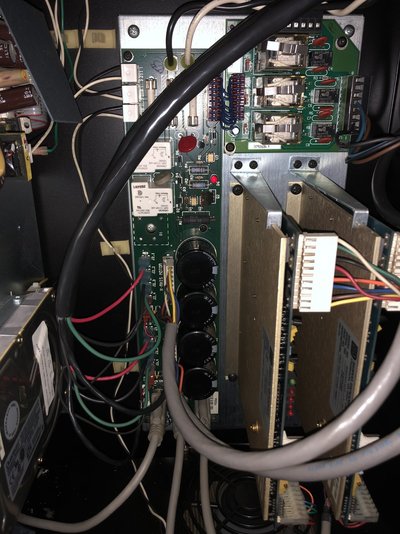

I think i commented on that controller in an old post you made Matt when you got this machine, more specifically aimed the controller. If you find the control box it will have rs 232 port in the box so you can dnc the controller and run Cam. The reason why i commented about the control was, I'm not sure if you were aware they are actually an anilam controller more or less. They derived from anilam and anilam is all but defunked now, re-badged and sold under the acu-rite name. My belief is there was very good reason for this after being one of the poor sods to have a anilam control retrofitted to a machine a lot of cost. Animal was bought Heidenhain ( seimens maybe? cant recall now) i believe to reduce the market and get rid of them out of the market, so there is a extremely high chance acu rite is owned by them also... This is very bad news from a spares point of view.

I would be interested to see onside the control box to see if they are identical to the anilams later versions knows as the Mk range and also to look at the servo drivers/ amplifier. If they are the same or not because the anilams servo drivers made by a company called glentec and are not good news at all.

Check to see if the controller box is rubber mounted, if it isn't, look at a doing so to save yourself a fortune in spares cost. The anilams used a hard drive, if yours is the same look at rubber mounting it or suspending the drive to keep vibrations away. I'm certain this was a ploy by anilam uk when they existed to make sure you pay a lot in spares and engineers costs.. everything was hard mounted and this is a sure way to a quick death of a controller on small machine which does not have the ability to dissipate vibration such as a vmc

I'm not trying to damped your thread, but as im sure you can see i had a lot very hard learnt experience which cos me a fortune i could not afford as a small one man band. After 3 to 4 years (and the machine being out of commission for long periods) i took the machine out of commission totally for these reasons. It was costing more than i could make out of it.

MattH

Member

- Messages

- 4,545

- Location

- Cornwall

The control is a DOS based program that is installed on a hard drive.

I plan to clone the drive to a spare so I can replace it if required. The pc is a standard AT based DX2-66 so would be easy to repair/replace.

I don’t know about the servo drives but the servos are standard DC premenent magnet motors.

There is an RS232 port but this is only so the controller can backup and retrieve files from a PC running the required interface software. You cannot send code to the machine that has been prepped elsewhere.

If anything complex went wrong I would just rip the lot out and replace with a new solution.

At this point I would added a servo driven quill and make it a fully 3 axis capable machine.

My background is in electronic servicing and I have spent the last 20 years working in IT so I’m not too worried.

Appreciate the comments though.

And yes the controller is doing look ahead as there is an option under the run menu to disable it.

I plan to clone the drive to a spare so I can replace it if required. The pc is a standard AT based DX2-66 so would be easy to repair/replace.

I don’t know about the servo drives but the servos are standard DC premenent magnet motors.

There is an RS232 port but this is only so the controller can backup and retrieve files from a PC running the required interface software. You cannot send code to the machine that has been prepped elsewhere.

If anything complex went wrong I would just rip the lot out and replace with a new solution.

At this point I would added a servo driven quill and make it a fully 3 axis capable machine.

My background is in electronic servicing and I have spent the last 20 years working in IT so I’m not too worried.

Appreciate the comments though.

And yes the controller is doing look ahead as there is an option under the run menu to disable it.

MattH

Member

- Messages

- 4,545

- Location

- Cornwall

@scott0031

You called it, no rubber mounting.

As I said, I'm not too concerned as a failure would give me the excuse to do a retrofit with a modern control.

And this isn't (at this time) a business machine for me so I am not reliant on it.

You called it, no rubber mounting.

As I said, I'm not too concerned as a failure would give me the excuse to do a retrofit with a modern control.

And this isn't (at this time) a business machine for me so I am not reliant on it.

Hood

Member

- Messages

- 17,984

- Location

- Carnoustie, Scotland

.....And this isn't (at this time) a business machine for me so I am not reliant on it.

Once you start using it though you will change your tune