stretchie_

Member

- Messages

- 53

Hello from Wiltshire

I have a cheapo ARC welder from Aldi or Lidl, can't remember which and I just bought a cheap MIG welder from an auction for £30.

I initially want to be able to 'knock up a bracket' here and there out of box section, angle and be able to make cages/boxes type things for the land rover.

I understand the common rule of "You buy cheap, you buy twice" but I don't have the money to buy a decent welder, perhaps once I have had a go then I can justify saving more money for a better one.

The MIG I got is a Ferm 100, I've done a search for it when I got it home... Not the best eh

Never touched a welder before, I'm still to buy the gear before I have a go, priced up apron, gloves, auto mask and Haynes manual from Halfords as I have a trade card and will get that soonish before I try and have a go.

Here's the welder

After doing some reading on the forum I have taken the gas shroud and wire tip off both came off and went back on fine, checked the wire moved alright which it did. The wire on the reel was old and a bit rusty so I cut it at the reel end and took several layers off the wire real until the rusty wire was gone.

I removed the wire from the liner and handle and fed the clean wire back up it. which all went well and there was no snagging and it went through easily.

I have no idea about the tensioner on the wire feeder, for now I did it up but not tight, my reasoning is that I can always do it up more to get the right tension. I took the wire feed wheel (??) off that has the grooves in for .6 or .8/.9 mm wire and gave it a wipe over to get the grime off it where it's been sat still.

I have a couple of questions that I'm hoping you can help with.

I downloaded a 'manual' for it from the Ferm website, it's basically just an exploded map of the unit with 3 or 4 pages in the middle as instructions, except that the instructions part is in several languages, none of which is English.

On the front it has a dial, which must be wire speed

Then at the bottom it has the on off switch, then it has two switches in the middle, 1/2 and min/max.

I understand that this means there are four settings:

Setting

1 & Min Lowest setting

1 & Max

2 & Min

2 & Max Highest setting

Is this correct?

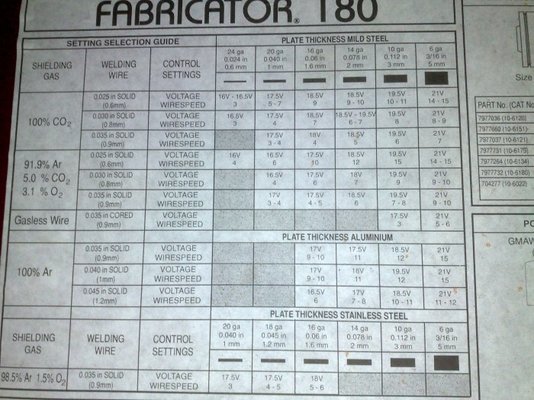

Here is the plate on the welder:

So, duty cyclye wise this means that on 80amp setting I can use it for 1 minute then it needs 9 mins rest to cool down and on 55amp setting I can use it for 2 minutes and it needs 8 minutes to cool down?

If that's right, that's only two settings but what about the four combinations with the min / max and the 1 / 2 buttons?

Last but not least, how can I test that it turns on and feeds wire? Can I plug it in, hold the handle in the air and pull trigger to see if it feeds wire through. It has an old gas bottle on the back but I am guessing that it needs replacing.

Cheers

Stretchie

I have a cheapo ARC welder from Aldi or Lidl, can't remember which and I just bought a cheap MIG welder from an auction for £30.

I initially want to be able to 'knock up a bracket' here and there out of box section, angle and be able to make cages/boxes type things for the land rover.

I understand the common rule of "You buy cheap, you buy twice" but I don't have the money to buy a decent welder, perhaps once I have had a go then I can justify saving more money for a better one.

The MIG I got is a Ferm 100, I've done a search for it when I got it home... Not the best eh

Never touched a welder before, I'm still to buy the gear before I have a go, priced up apron, gloves, auto mask and Haynes manual from Halfords as I have a trade card and will get that soonish before I try and have a go.

Here's the welder

After doing some reading on the forum I have taken the gas shroud and wire tip off both came off and went back on fine, checked the wire moved alright which it did. The wire on the reel was old and a bit rusty so I cut it at the reel end and took several layers off the wire real until the rusty wire was gone.

I removed the wire from the liner and handle and fed the clean wire back up it. which all went well and there was no snagging and it went through easily.

I have no idea about the tensioner on the wire feeder, for now I did it up but not tight, my reasoning is that I can always do it up more to get the right tension. I took the wire feed wheel (??) off that has the grooves in for .6 or .8/.9 mm wire and gave it a wipe over to get the grime off it where it's been sat still.

I have a couple of questions that I'm hoping you can help with.

I downloaded a 'manual' for it from the Ferm website, it's basically just an exploded map of the unit with 3 or 4 pages in the middle as instructions, except that the instructions part is in several languages, none of which is English.

On the front it has a dial, which must be wire speed

Then at the bottom it has the on off switch, then it has two switches in the middle, 1/2 and min/max.

I understand that this means there are four settings:

Setting

1 & Min Lowest setting

1 & Max

2 & Min

2 & Max Highest setting

Is this correct?

Here is the plate on the welder:

So, duty cyclye wise this means that on 80amp setting I can use it for 1 minute then it needs 9 mins rest to cool down and on 55amp setting I can use it for 2 minutes and it needs 8 minutes to cool down?

If that's right, that's only two settings but what about the four combinations with the min / max and the 1 / 2 buttons?

Last but not least, how can I test that it turns on and feeds wire? Can I plug it in, hold the handle in the air and pull trigger to see if it feeds wire through. It has an old gas bottle on the back but I am guessing that it needs replacing.

Cheers

Stretchie

.....Gav

.....Gav