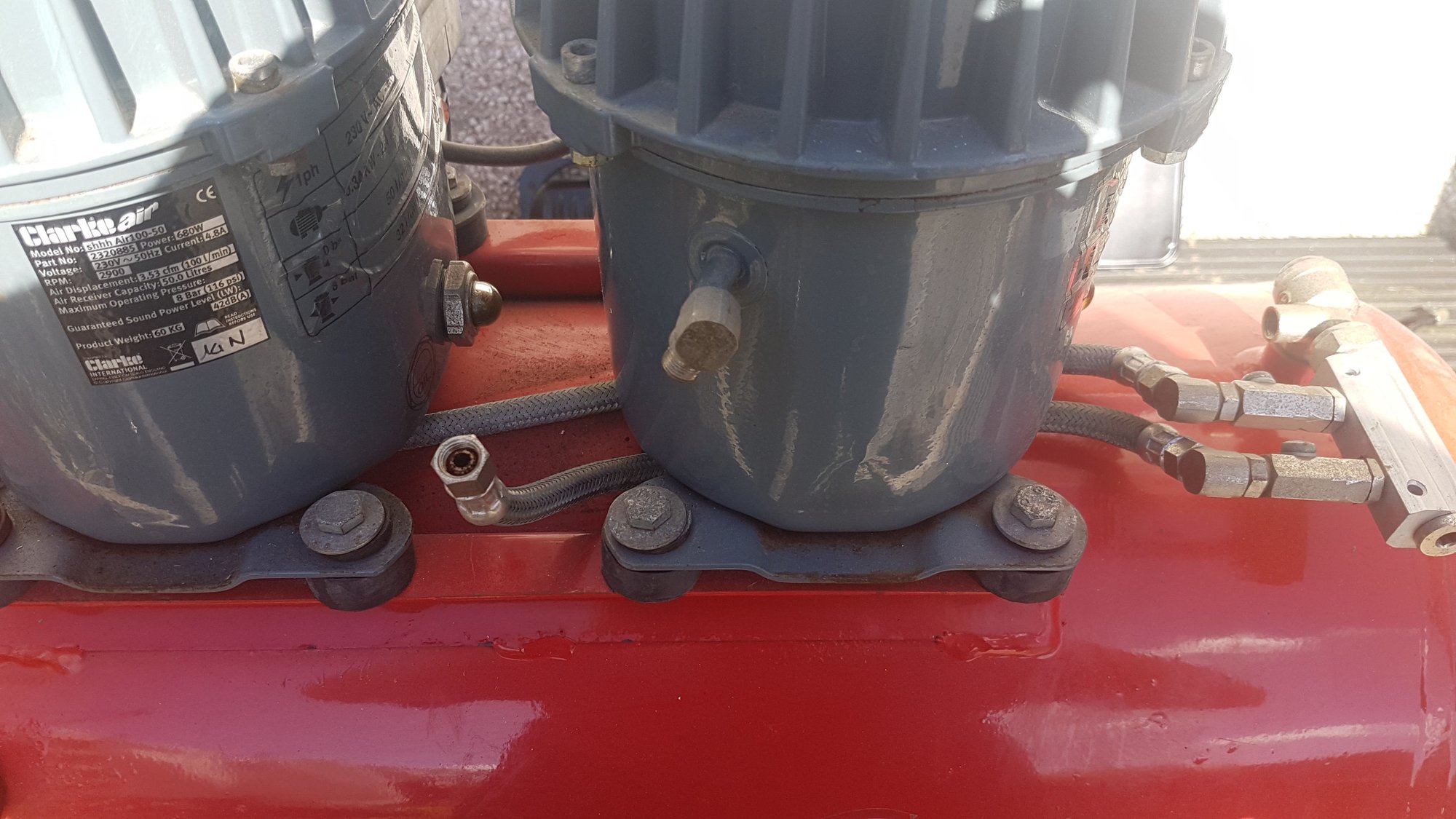

My Compressor has stopped filling the tank, and blowing smoke from the Air intakes.

Ive checked the non return valves and all seem correct and functioning but im at a lose as to why its suddenly stopped filling the tank, gets to about 1psi and thats it. Ive always used clarke Oil and levels seem ok, the other thing is that when i checked the non return valves they were full of oily water!

Any ideas guys?

Any ideas guys?

Ive checked the non return valves and all seem correct and functioning but im at a lose as to why its suddenly stopped filling the tank, gets to about 1psi and thats it. Ive always used clarke Oil and levels seem ok, the other thing is that when i checked the non return valves they were full of oily water!

, but that Member hasn't been on the forum since May, 2018 so I doubt if you'll get a response.

, but that Member hasn't been on the forum since May, 2018 so I doubt if you'll get a response.