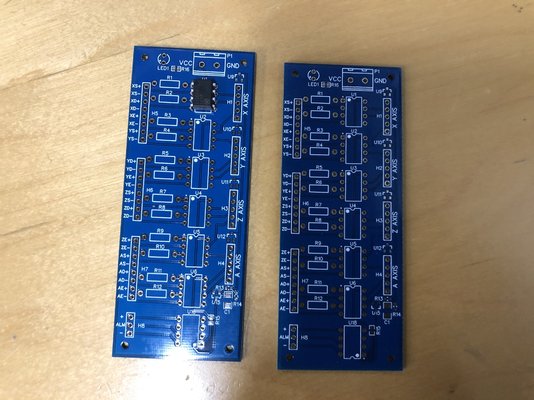

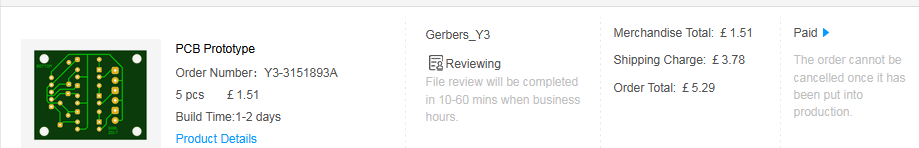

Just a quick question. Whats the cheapest, simplest, quickest, easiest way of producing a circuit board .

I know I can get some done in China but I would rather do it myself if its not too hard. particularly for the speed part.

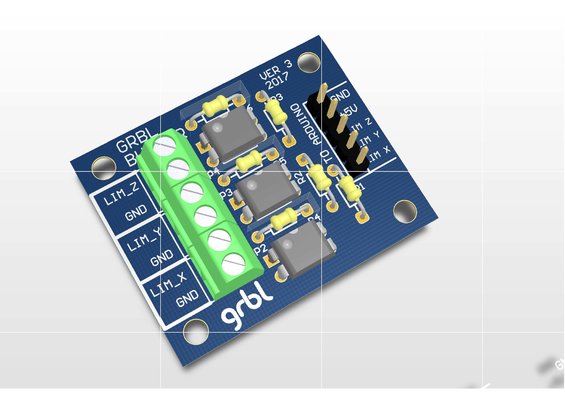

This is what I am trying to create.. https://github.com/gnea/grbl/wiki/Wiring-Limit-Switches and you can see why on that page also.

Quote

Capacitors for noise filtering

Even if you do use NC contacts, you still need those 104 (0.1uF) capacitors, as close to the Arduino as you can place them. You can argue all day that those caps won't make a difference since the caps are shorted out by the switches. The explanation for this phenomenon is quite long but the first power line glitch will convince you otherwise. (Plug in your blender next to the CNC's AC plug and turn it on. Your CNC should still behave normally despite the blender.)

Side benefit: With NC switches, the connection is broken cleanly when you hit home position, therefore no contact bounce occurs. (Contact bounce occurs only during switch closure, NOT during switch opening.) End quote

Seems strange they built the board but still suggest adding capacitors to the arduino but coulld they not add them to the Buffer when designing it instead??

I know I can get some done in China but I would rather do it myself if its not too hard. particularly for the speed part.

This is what I am trying to create.. https://github.com/gnea/grbl/wiki/Wiring-Limit-Switches and you can see why on that page also.

Quote

Capacitors for noise filtering

Even if you do use NC contacts, you still need those 104 (0.1uF) capacitors, as close to the Arduino as you can place them. You can argue all day that those caps won't make a difference since the caps are shorted out by the switches. The explanation for this phenomenon is quite long but the first power line glitch will convince you otherwise. (Plug in your blender next to the CNC's AC plug and turn it on. Your CNC should still behave normally despite the blender.)

Side benefit: With NC switches, the connection is broken cleanly when you hit home position, therefore no contact bounce occurs. (Contact bounce occurs only during switch closure, NOT during switch opening.) End quote

Seems strange they built the board but still suggest adding capacitors to the arduino but coulld they not add them to the Buffer when designing it instead??