You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

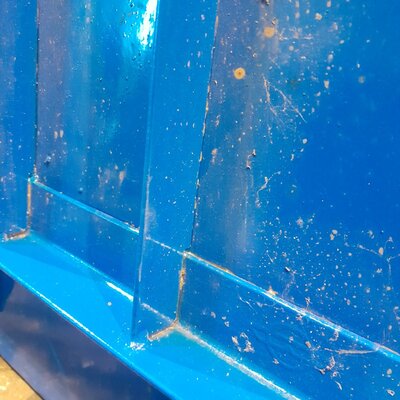

Chinese motorcycle ramp

- Thread starter Bornfree

- Start date

addjunkie

Member

- Messages

- 14,372

- Location

- Northumberland. Reet oot in the sticks

They say 1/2” of weld will hold half a ton.two ways of thinking ,,

1 , its done ok up to now

2 best stick a bit extra on it because you can

id be second school of thought , then again I ride BMWs now not Ducati as I used to.

It'll be fine for a Hardly Davidson!

Not everything needs fully welding to death - although seeing some of my colleagues drawings, you might think so. Instructed a few in the meaning of welding symbols to inidcated number of welds, length of welds, spacing of welds. No whether the supplier's welder knows them too is another matter! Quite often they don't.

I've also had to put specific instructions on drawings not to drag an abrasive disc or flap wheel all over the finished article, making it look terrible when painting highlights all the gouges, when I know it might go to one particular guy at one supplier!

What is the lift rated for?

I've also had to put specific instructions on drawings not to drag an abrasive disc or flap wheel all over the finished article, making it look terrible when painting highlights all the gouges, when I know it might go to one particular guy at one supplier!

What is the lift rated for?

mig it ,. just wheres handy and stress bearingAlthough I’m not a qualified engineer, that doesn’t look good to me. I tend to over engineer things and in this case I’d happily be reinforcing it with the stick welding facility of my R-tech 180 mig.

450kgNot everything needs fully welding to death - although seeing some of my colleagues drawings, you might think so. Instructed a few in the meaning of welding symbols to inidcated number of welds, length of welds, spacing of welds. No whether the supplier's welder knows them too is another matter! Quite often they don't.

I've also had to put specific instructions on drawings not to drag an abrasive disc or flap wheel all over the finished article, making it look terrible when painting highlights all the gouges, when I know it might go to one particular guy at one supplier!

What is the lift rated for?

Ive got one that has welds that look like that factory, its 15+ years old, was originally for 125/250 sized bikes after I bought it thinking the harley in the auction photo was a full sized dresser not a 125 faked up to look like one, and its been extended to make it longer with bars to support the onramp so it doesnt droop with the weight of a bike on it during a lift and has since had my gpz1100b2 twinshock and other lardy 80's heavyweights on it. Its narrow too but that suited my ultra narrow workshop back then so a happy mistake.

At one point I moved a harrison L5 lathe and cabinet using it as the platform to get the lump up to trailer height for loading after taking the wheel clamp and loading ramp off so it was basically flat.

Still going strong today, the original style front wheel clamp is a disaster though, one of those over centre flopping ones is a good upgrade.

I torched hook holes in it too so I could secure things on it better. I take the front wheel clamp off and use it as a loading platform for the front bench, just roll the bike off it onto the next one with a plate of steel as a bridge...

At one point I moved a harrison L5 lathe and cabinet using it as the platform to get the lump up to trailer height for loading after taking the wheel clamp and loading ramp off so it was basically flat.

Still going strong today, the original style front wheel clamp is a disaster though, one of those over centre flopping ones is a good upgrade.

I torched hook holes in it too so I could secure things on it better. I take the front wheel clamp off and use it as a loading platform for the front bench, just roll the bike off it onto the next one with a plate of steel as a bridge...

Actually the bottom part that contains the hydraulic ram is absolutely fine.What are the welds like for the heaviest loaded parts? Around the ram, pivot points, scissor mechanism or whatever it has.

then never worryActually the bottom part that contains the hydraulic ram is absolutely fine.