Hi all

Second post & in need of help so soon

The PCB on my ederly Cebora Auto Star 180 ( Model: 838 )Mig welder, looks to be dead

Here's the story so far.

A couple of years back the wire feed became erratic( Feeding wire at full rate ), it was noticed that if the wire speed knob was wiggled a little, the wire feed would work normally for a short while.

It came to the point that unless pressure was held on the knob, I could not controll the wire feed rate ( Flat out once more )

Not being a complete numty when it comes to electronic work, I removed the PCB, de-soldered the board's potentiometer & gave it a good clean with some low pressure compressed air.

I noticed that the pot had started to come appart .... In hind sight, I guess this would have been the ideal time to replace the thing

So much work on at the time I needed it fixed quick as downtime would have been costing me a bundle

Anyway, back to the story.

I re-soldered the potentiometer back on to the board, when I fitted the Red mounting collar I placed a small non conductive washer between the collar & pot.

This made sure a little pressure was exerted on the pot.

The welder worked without fault for almost 2 years untill recently, went to use the set & the old problem had returned .... Wire feeding at full rate, the control knob had no effect.

Cock sure that the potententiomter was faulty a new one of the same value was bought .... Well 2 because I was unable to determine if I needed a linear one or a log one !!??

Fitted the linear pot first .... The welder was still the same, wire feeding at the full rate.

I then fitted the log pot, this gave me some tiny degree of wire controll but only on a tiny part of the pots range .... only a few mm or so.

So at this point, unless I was welding on full current, the mig welder was next to useless to me

After spending many hour's searching the internet, I came uppon a welder PCB repair service & promptly sent the board off for a professional repair.

Best point out at this stage that when the board left me .... On the face of things all was well except the wire feed problem !!??

The board was still swiching both the welders main contactor relay & still switching the shielding gas.

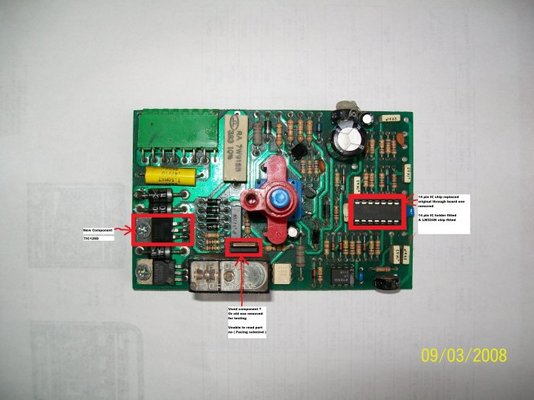

The board was gone from me for a good few weeks & was returned as a fully repaired board, earlier this week, not worried about the repair time as I know how difficult it can be to source parts at times.

Oh deep joy .... At last I can get back to the work on my kit car project

Imagine my dissmay when I fitted the board back in the welder, just to find that it was now completely dead

The board is now not swiching the power, gas or wire, all I get now when I press the trigger on the torch is a click from the relay on the PCB

Checked for loose connections but none found.

Does any kind soul on here have a schematic diagram for this board ?

I know the set is about 20 years old but it has been a good servant to me, simply just don't want to stick it on ebay for spares or repair .... Not in me to do that if it can't be fixed & cant bear to chuck it in the skip

Sorry for the long, long post but I find it best to give the full story at the outset .... Help others to help me & all that

Second post & in need of help so soon

The PCB on my ederly Cebora Auto Star 180 ( Model: 838 )Mig welder, looks to be dead

Here's the story so far.

A couple of years back the wire feed became erratic( Feeding wire at full rate ), it was noticed that if the wire speed knob was wiggled a little, the wire feed would work normally for a short while.

It came to the point that unless pressure was held on the knob, I could not controll the wire feed rate ( Flat out once more )

Not being a complete numty when it comes to electronic work, I removed the PCB, de-soldered the board's potentiometer & gave it a good clean with some low pressure compressed air.

I noticed that the pot had started to come appart .... In hind sight, I guess this would have been the ideal time to replace the thing

So much work on at the time I needed it fixed quick as downtime would have been costing me a bundle

Anyway, back to the story.

I re-soldered the potentiometer back on to the board, when I fitted the Red mounting collar I placed a small non conductive washer between the collar & pot.

This made sure a little pressure was exerted on the pot.

The welder worked without fault for almost 2 years untill recently, went to use the set & the old problem had returned .... Wire feeding at full rate, the control knob had no effect.

Cock sure that the potententiomter was faulty a new one of the same value was bought .... Well 2 because I was unable to determine if I needed a linear one or a log one !!??

Fitted the linear pot first .... The welder was still the same, wire feeding at the full rate.

I then fitted the log pot, this gave me some tiny degree of wire controll but only on a tiny part of the pots range .... only a few mm or so.

So at this point, unless I was welding on full current, the mig welder was next to useless to me

After spending many hour's searching the internet, I came uppon a welder PCB repair service & promptly sent the board off for a professional repair.

Best point out at this stage that when the board left me .... On the face of things all was well except the wire feed problem !!??

The board was still swiching both the welders main contactor relay & still switching the shielding gas.

The board was gone from me for a good few weeks & was returned as a fully repaired board, earlier this week, not worried about the repair time as I know how difficult it can be to source parts at times.

Oh deep joy .... At last I can get back to the work on my kit car project

Imagine my dissmay when I fitted the board back in the welder, just to find that it was now completely dead

The board is now not swiching the power, gas or wire, all I get now when I press the trigger on the torch is a click from the relay on the PCB

Checked for loose connections but none found.

Does any kind soul on here have a schematic diagram for this board ?

I know the set is about 20 years old but it has been a good servant to me, simply just don't want to stick it on ebay for spares or repair .... Not in me to do that if it can't be fixed & cant bear to chuck it in the skip

Sorry for the long, long post but I find it best to give the full story at the outset .... Help others to help me & all that