Barlidge

Member

- Messages

- 1,064

- Location

- Langford, Bedfordshire, UK

So have finally got round to looking at the damp corner of my caravan, know about it for a while and it was coming in from the awning rail which I temporarily sealed a while back and hoped it would dry out - nope!

Have started stripping back some of the interior to let it start drying while I look at resealing the awning rail and some other external bits. Most of the timber is not too bad and am hoping it will dry but the corner plywood piece is too far gone I think and while I dont think is is integral to the strength of the box it does have the awning rail screwed into it which is under tension when fitted and it also serves to bond the GRP/side panel joint.

So my current thought process is to make some surgical cuts as shown in the picture below with the yellow dashed lines - these should hopefully give me enough access to replace that piece while being able to hide most of the joins either behind the top of the wall unit or behind the corner shelf. The two areas that will be visible can be blended in with matching tape as the original panel joint in the red dashed lines.

All thoughts and opinions welcome.

Damp area

Delaminated Plywood Corner Piece

Inside Rear GRP - Only the Ply seems to have suffered

Roof Composition - Outer plastic covering, 3mm ply bonded to polystyrene bonded to 3mm ply.

Above PLY Diagonal Piece

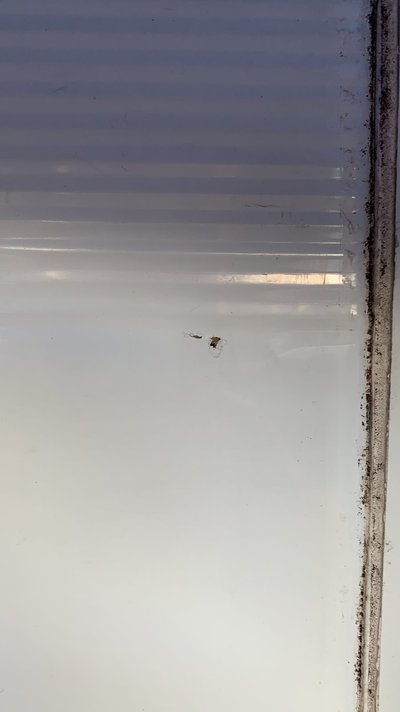

Behind Awning Rail

Proposed Cuts

Have started stripping back some of the interior to let it start drying while I look at resealing the awning rail and some other external bits. Most of the timber is not too bad and am hoping it will dry but the corner plywood piece is too far gone I think and while I dont think is is integral to the strength of the box it does have the awning rail screwed into it which is under tension when fitted and it also serves to bond the GRP/side panel joint.

So my current thought process is to make some surgical cuts as shown in the picture below with the yellow dashed lines - these should hopefully give me enough access to replace that piece while being able to hide most of the joins either behind the top of the wall unit or behind the corner shelf. The two areas that will be visible can be blended in with matching tape as the original panel joint in the red dashed lines.

All thoughts and opinions welcome.

Damp area

Delaminated Plywood Corner Piece

Inside Rear GRP - Only the Ply seems to have suffered

Roof Composition - Outer plastic covering, 3mm ply bonded to polystyrene bonded to 3mm ply.

Above PLY Diagonal Piece

Behind Awning Rail

Proposed Cuts

I am thinking a small piece of aluminium patch sika'd on from the inside then clean the outside up and JB weld over it and paint.

I am thinking a small piece of aluminium patch sika'd on from the inside then clean the outside up and JB weld over it and paint.