Rich.C

Member

- Messages

- 142

Hi Fellas,

Would very much appreciate your advice to help me learn how to tackle some car bodywork.

I've got an elderly BMW and among the many jobs needed doing is to cut out and replace the rear outer wheel arches. I bought the repair panels and hope to use as little of them as possible.

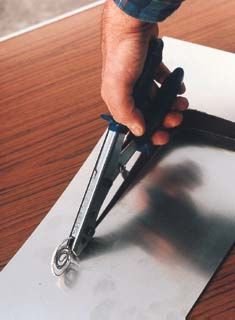

The first question is: what is the best tool/saw for cutting both the new repair panel and the quarter panel of the car without distorting the cut edges or leaving them very rough?

(I have an air compressor)

Would you butt joint this sort of work? If so, what size gap would be needed? and are those Intergrips useful for this sort of stuff?

Do you cut the repair panel to shape and then offer it up to the car and mark around it?

The black paint that repair/replacement panels come covered with, is this suitable to leave on the inside of (e.g. an outer sill) or does it have to be removed and primers etc used?

Finally what is the best technique when welding this sort of thickness (0.8mm)? I've got a Clarke 160en which I'm practising with at the moment on some scrap 0.8 stuff (using 0.6 wire, Argon/CO2 the lowest setting is 30amps.) Am finding tacking it then coming back between the tacks with some longer runs seems ok but can be hard to avoid distortion and am not sure how long the runs should be or how much gap to leave between tacks.

Apologies for the essay but I guess If I don't ask I'll never learn.

but I guess If I don't ask I'll never learn.

Thanks a lot,

Rich.

Would very much appreciate your advice to help me learn how to tackle some car bodywork.

I've got an elderly BMW and among the many jobs needed doing is to cut out and replace the rear outer wheel arches. I bought the repair panels and hope to use as little of them as possible.

The first question is: what is the best tool/saw for cutting both the new repair panel and the quarter panel of the car without distorting the cut edges or leaving them very rough?

(I have an air compressor)

Would you butt joint this sort of work? If so, what size gap would be needed? and are those Intergrips useful for this sort of stuff?

Do you cut the repair panel to shape and then offer it up to the car and mark around it?

The black paint that repair/replacement panels come covered with, is this suitable to leave on the inside of (e.g. an outer sill) or does it have to be removed and primers etc used?

Finally what is the best technique when welding this sort of thickness (0.8mm)? I've got a Clarke 160en which I'm practising with at the moment on some scrap 0.8 stuff (using 0.6 wire, Argon/CO2 the lowest setting is 30amps.) Am finding tacking it then coming back between the tacks with some longer runs seems ok but can be hard to avoid distortion and am not sure how long the runs should be or how much gap to leave between tacks.

Apologies for the essay

but I guess If I don't ask I'll never learn.

but I guess If I don't ask I'll never learn.Thanks a lot,

Rich.

Last edited:

-

-