You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Can you gas weld aluminum

- Thread starter Jackel

- Start date

malcolm

& Clementine the Cat

- Messages

- 9,821

- Location

- Bedford UK

My limited understanding is a deoxidising flame is used for aluminium. It's reactive stuff and you need to remove it's own oxide layer, so less oxygen is used in the gas torch in the hope of pulling oxygen out of the hot aluminium.

Mild steel is less reactive so the flame is more optimised for performance rather than worrying about the tiniest bit of oxygen.

That's why the flame colour is different. Not that I've ever tried gas welding aluminium, but a friend has. From his results I would guess it's doable but tricky.

Mild steel is less reactive so the flame is more optimised for performance rather than worrying about the tiniest bit of oxygen.

That's why the flame colour is different. Not that I've ever tried gas welding aluminium, but a friend has. From his results I would guess it's doable but tricky.

Hello Jackel,

the flux gives off a yellow haze, which makes it difficult to see the weld pool with normal green lenses. Blue lenses are recommended but not that easy to find.

I use a neutral flame by the way but fairly soft, 3mm sheet is fairly easy, but gets harder as you go thinner. Like all things if you do it regularly you get better. I saw a body man at Aston Martin doing a butt weld on a wing, no filler just running the torch along the seam.

Alec

the flux gives off a yellow haze, which makes it difficult to see the weld pool with normal green lenses. Blue lenses are recommended but not that easy to find.

I use a neutral flame by the way but fairly soft, 3mm sheet is fairly easy, but gets harder as you go thinner. Like all things if you do it regularly you get better. I saw a body man at Aston Martin doing a butt weld on a wing, no filler just running the torch along the seam.

Alec

Paul.

Moderator

- Messages

- 7,017

- Location

- Northampton. UK

The oxy acetylene flame should be neutral to very slightly carburising, use a pure aluminium or 5% si filler rod, not too much flux, the way to apply flux to the rod is called tufting, warm the end of the rod with the torch, dip in the powdered flux, then hold the rod so that it points upwards and gently warm the flux until it melts and runs down the rod, this will evenly coat it, it looks a bit like varnish if you get it right, as with other welding processes, pre cleaning of the joint is vital, the fluxes used are quite corrosive and must be cleaned off immediately after welding.

There is no colour change with aluminium when it gets hot, so recognising when it melts is what most beginners, (and some that are not beginners) struggle with, we used to say one minute its on the bench, next its in your boots.

There is no colour change with aluminium when it gets hot, so recognising when it melts is what most beginners, (and some that are not beginners) struggle with, we used to say one minute its on the bench, next its in your boots.

Just like to add to what TIG Paul says, only take some aluminium welding flux out of the container to do the job and put the lid back on. Do not return the left overs to the container as it attrarcts moisture from the air like crazy. A couple of hours after you finish welding your left over will be running like water.

Ragnarok

Enthusiast

- Messages

- 697

- Location

- Wales

hey there, I just started doing aluminium welding with oxy acetylene my self the flame goes orange even when not actually welding if even a tiny bit of flux gets on the nozzle, you don't see the orange sodium flare at all if you use GWF (gas welding flux) welding lenses (they are what we have in the uk rather than blue ones like the americans), I've been practising on 2mm aluminium and it seems pretty easy to do though I'm sure 3mm+ would be easier but i just had a few 2mm off cuts from a portable bbq I made in the summer, but it's also pretty easy to burn holes if you're not careful (never try to stop then restart before the metal has cooled completely haha) the only way I've used the flux so far is the way described in a welding book i have, and that is to mix a small amount with methylated spirits then brush it on to the metal this seems to work well and the spirit burns off as soon as you point the torch at it leaving a drycoating of flux on the metal, and warm the rod and dip it in to the dry flux then warm it till the flux runs all the way down the rod (gotta be careful not to melt the rod though)

anyway works well and the welds are strong (as strong as the base you can try to break it all you like you just end up with a very twisted piece of aluminium) and not BAD looking either, I'm sure i will get them to look really nice with a bit more practice though.

anyway that's me experience of it (only had the flux and rods for a couple of days though)

anyway works well and the welds are strong (as strong as the base you can try to break it all you like you just end up with a very twisted piece of aluminium) and not BAD looking either, I'm sure i will get them to look really nice with a bit more practice though.

anyway that's me experience of it (only had the flux and rods for a couple of days though)

metalmicky

Member

- Messages

- 5

Keep practicing, gassing ally is great fun and very quick, still do the odd body, when the metal drops to the floor remember who is holding the heat! and speed up your reactions, in time you should be able to weld with torch in wrong hand, arms crossed and go backwards,well party tricks but >>>>>>

seriously though keep at it as it is so much more satisfying than migging especially on a cold day, have fun Mike

seriously though keep at it as it is so much more satisfying than migging especially on a cold day, have fun Mike

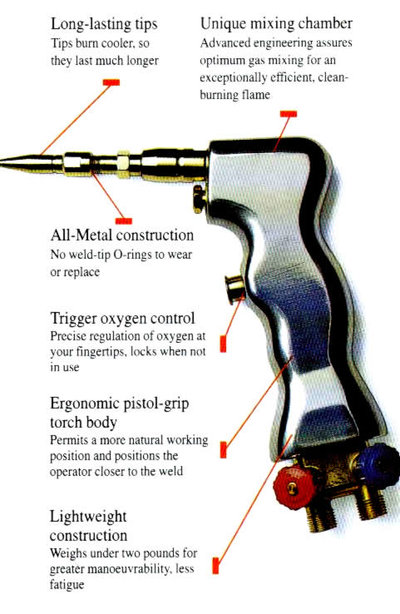

Yes you can most definetly weld alluminium with gas Use the DCH2000

watch the video on http://amweld.com.au and you can got to Youtube and see many more videos of it in use Just use the search bar on youtube like you do for google and type in DCH2000 or Henrob. The other gentalman was correct about a d-oxidised flame.

I own one and use one because ive never been a good welder now ive welded a chopper chassis with it, it burns on 4 psi oxy-accet and you turn it up to 20psi for cutting it will weld mild steel to stainless wich i have done putting stainless steel nuts behind the mild steel forward control mounts on my chassis for one.

It dose take time to learn everything it dose there is no question about that.

Ive not even tried everything yet and ive owned it for over 1-1/2 years ive had no need to. ive welded car pannel with minimal distortion.(new type car pannel).

I have a bit of trouble welding two thicknesses of steel i admit but only because ive not practiced much with that there has to be techneque to it.

most mild steel it with a neutral flame JOF.

stainless to mild the same.

d-oxidised for alluminium.Ive tried with mabe the wrong rod or some tweeking on my techneque requiered.

the hire of bottles is an issue as they last much longer.

i can weld in the wind and rain and do not need a power source. so ideal for a farmer or the like.

it will weld rusty metal to rusty metal and is strong.

the welds are not as brittle as tig.

minimal personal protective equipment requiered, Only dark glasses and short gloves.

minnimal or no splatter and very little clean up the fall back or underlay of the weld fully penertrated sits perfectly flush with the metal.

Fusion welding is great with this welder.

very local heat only in the direct weld area.

you can get nossels to do fine jewlery so good for an artist or sculpturer.

and will cut through thick mild steel like a plasma.

ive heard you can weld a coke can with it but i dont have the fine nossel.

It was a Aussie invention and NASSA use it on there rockets due to local heat and minimal distortion.

Please ive written all this to prevent questions as if your interested you can do what id did check it out on the links ive given you.

I can only say that they are not fudged they are real.(you have my word).

One more thing the angle of the tip must be 15 deg - 20 deg.

I don't know what happened there i lost my other post and ended up on the previous post dam oh well im leaving it here now sorry about that.

http//www.amweld.com.au. you can see this welder on Youtube if you do a search for DCH 2000 or Henrob.

watch the video on http://amweld.com.au and you can got to Youtube and see many more videos of it in use Just use the search bar on youtube like you do for google and type in DCH2000 or Henrob. The other gentalman was correct about a d-oxidised flame.

I own one and use one because ive never been a good welder now ive welded a chopper chassis with it, it burns on 4 psi oxy-accet and you turn it up to 20psi for cutting it will weld mild steel to stainless wich i have done putting stainless steel nuts behind the mild steel forward control mounts on my chassis for one.

It dose take time to learn everything it dose there is no question about that.

Ive not even tried everything yet and ive owned it for over 1-1/2 years ive had no need to. ive welded car pannel with minimal distortion.(new type car pannel).

I have a bit of trouble welding two thicknesses of steel i admit but only because ive not practiced much with that there has to be techneque to it.

most mild steel it with a neutral flame JOF.

stainless to mild the same.

d-oxidised for alluminium.Ive tried with mabe the wrong rod or some tweeking on my techneque requiered.

the hire of bottles is an issue as they last much longer.

i can weld in the wind and rain and do not need a power source. so ideal for a farmer or the like.

it will weld rusty metal to rusty metal and is strong.

the welds are not as brittle as tig.

minimal personal protective equipment requiered, Only dark glasses and short gloves.

minnimal or no splatter and very little clean up the fall back or underlay of the weld fully penertrated sits perfectly flush with the metal.

Fusion welding is great with this welder.

very local heat only in the direct weld area.

you can get nossels to do fine jewlery so good for an artist or sculpturer.

and will cut through thick mild steel like a plasma.

ive heard you can weld a coke can with it but i dont have the fine nossel.

It was a Aussie invention and NASSA use it on there rockets due to local heat and minimal distortion.

Please ive written all this to prevent questions as if your interested you can do what id did check it out on the links ive given you.

I can only say that they are not fudged they are real.(you have my word).

One more thing the angle of the tip must be 15 deg - 20 deg.

I don't know what happened there i lost my other post and ended up on the previous post dam oh well im leaving it here now sorry about that.

http//www.amweld.com.au. you can see this welder on Youtube if you do a search for DCH 2000 or Henrob.

Last edited by a moderator:

pidgeon chit welder

sticking metal since 1962

- Messages

- 961

Just watched one of the biker build offs on sky and the guy was making an tank from aluminum but was gas welding it with a very orange looking flame

When I did some gas welding at college it was a blue flame so any ideas how,why,what the set up was

Orange flame has more fuel in the ration so burns yellowish it is just a smidgeom on past neutral flame and well before a smoking carburizing one , use green palm olive soap 1/2 inch away from weld , heat till it goes very dark for preheating area to start ..you can now weld using borax or a sif flux