Feet 'n Inches

Out of the rat-race at last

- Messages

- 544

- Location

- Devon, GB

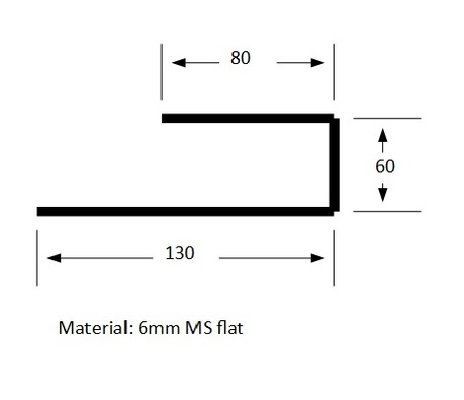

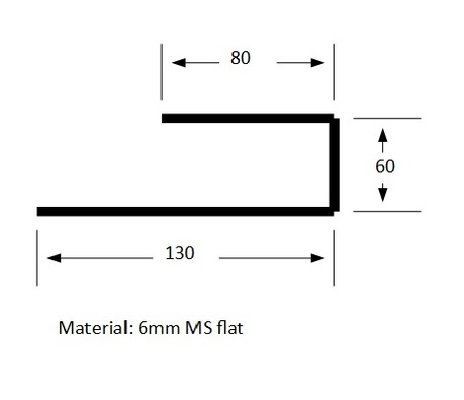

I haven't used a press-brake in years, so I'm no longer sure of their capabilities. I had an idea that involves folding some 6 mm plate into an odd-leg channel around 6" in length. To save time and money, these could be formed in 900 mm lengths and I could then cut them to size. Here's a plan of what I intend.

Could this be done on a standard press-brake? No problem if not because I can always weld the individual pieces of flat together although that would obviously take longer.

Could this be done on a standard press-brake? No problem if not because I can always weld the individual pieces of flat together although that would obviously take longer.