Monkey Harris

Member

- Messages

- 948

- Location

- northampton nn5

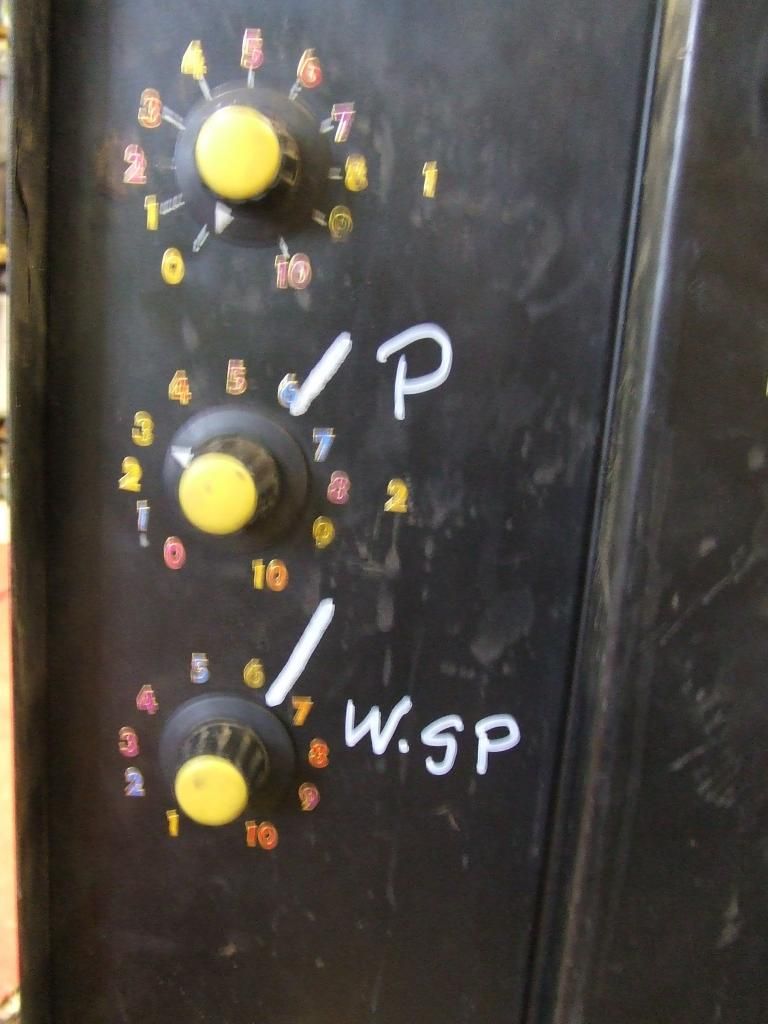

Disconnected it while testing and tidying..

Will mount it in a box if I keep the welder, or fit another to the front..

Will mount it in a box if I keep the welder, or fit another to the front..