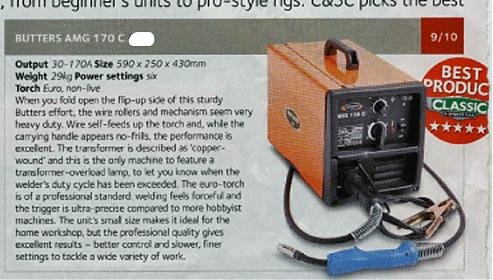

Ok, I've still not seen that article in the Classic Car mag that voted the Butters 170c Mig as Best Buy, but I like to make my own mind up about things anyway, so I bought one to have a play with :-

:-

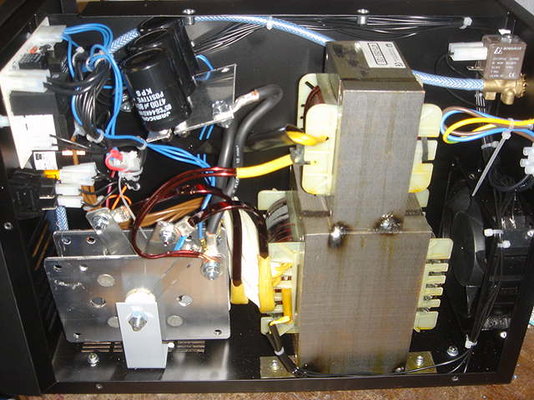

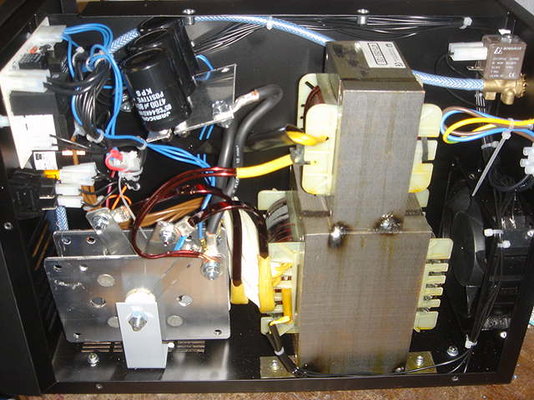

First impressions taking it out of the box was that it was a heavy little sod! so must have plenty of guts. Took the side case off & had a look inside...

Copper wound main transformer, large choke transfomer & 3 smoothing capacitors that should all lead to an excellent arc.

It's supplied with a decent industrial 2 gauge argon gas regulator & 3 metre Parweld euro-torch (cheaper 'Eco' model & not the better 'Ergo' model, but fine all the same).

Decent front panel with nice switches etc.

Then I had a look on the other side...

Oh no! a horrible plastic wire feed. To be honest, you have to spend £4-£500+ in the UK to get a really decent quality wire feed assembly, and the model used is one of the better, more reliable ones; I was hoping for something more substantial though!

Down to the weld tests...

Performed well on low current, with a nice crisp arc condition & smooth results. The minimum setting is 30amps (15.5v) which isn't the lowest on the market, but gave good results.

Moving through the voltage settings, on both 0.6mm & 0.8mm wire, it gave nice smooth results.

When I cranked it up toward the top settings the arc quality seemed to deteriorate quite a bit, with increased spatter, but I think this was just down to the small wire feed motor trying to keep up with the increased feed-rate needed for the extra power, as the end results were fine.

A did just a couple of 6 inch runs on the top setting & it 'cut-out', just stopped No overload warning light on though?

No overload warning light on though?

ME! using a standard 13amp fused plug it had blown the fuse; so, welding on the very top setting it needs to be wired into a 16amp supply (fine on the setting below though).

it had blown the fuse; so, welding on the very top setting it needs to be wired into a 16amp supply (fine on the setting below though).

I'm not sure about the market they are aiming this machine at though? It's sold as an Automotive/DIY machine. It's just about the same physical size & weight of any other 'Hobby' MIG. If it were a similar price to any other higher amperage hobby mig ( a bit more given that it has a euro torch & copper windings etc.) it would be a clear winner. But it's not - it's £350, which put's it way beyond the price bracket of 'Hobby'machines. In that price range you are looking at bigger, wheeled mounted machines which have a large gas cylinder carrier on the rear etc.

The Clarke 175TE is a similar price & is a cracking little set. OK it doesn't have a euro-torch, but internally it has a slightly better spec. (namely an industrial style Contactor unit), has a better Duty Cycle & is wheel mounted so you can stick your gas cylinder on the rear & move it all easily around the workshop.

I reckon this machine is perfect for light duty On-Site work, such as erecting wrought iron gates & railings etc. It has plenty of punch at the top end so would quite easily put gates & railings together, can be used with flux cored gas-less wire, so no need to hump gas cylinders around, & is very compact & portable to chuck in the back of the van.

As an automotive/DIY machine, there is better value for money.

All in my humble opinion of course.

weldequip

First impressions taking it out of the box was that it was a heavy little sod! so must have plenty of guts. Took the side case off & had a look inside...

Copper wound main transformer, large choke transfomer & 3 smoothing capacitors that should all lead to an excellent arc.

It's supplied with a decent industrial 2 gauge argon gas regulator & 3 metre Parweld euro-torch (cheaper 'Eco' model & not the better 'Ergo' model, but fine all the same).

Decent front panel with nice switches etc.

Then I had a look on the other side...

Oh no! a horrible plastic wire feed. To be honest, you have to spend £4-£500+ in the UK to get a really decent quality wire feed assembly, and the model used is one of the better, more reliable ones; I was hoping for something more substantial though!

Down to the weld tests...

Performed well on low current, with a nice crisp arc condition & smooth results. The minimum setting is 30amps (15.5v) which isn't the lowest on the market, but gave good results.

Moving through the voltage settings, on both 0.6mm & 0.8mm wire, it gave nice smooth results.

When I cranked it up toward the top settings the arc quality seemed to deteriorate quite a bit, with increased spatter, but I think this was just down to the small wire feed motor trying to keep up with the increased feed-rate needed for the extra power, as the end results were fine.

A did just a couple of 6 inch runs on the top setting & it 'cut-out', just stopped

No overload warning light on though?

No overload warning light on though?ME! using a standard 13amp fused plug

it had blown the fuse; so, welding on the very top setting it needs to be wired into a 16amp supply (fine on the setting below though).

it had blown the fuse; so, welding on the very top setting it needs to be wired into a 16amp supply (fine on the setting below though).I'm not sure about the market they are aiming this machine at though? It's sold as an Automotive/DIY machine. It's just about the same physical size & weight of any other 'Hobby' MIG. If it were a similar price to any other higher amperage hobby mig ( a bit more given that it has a euro torch & copper windings etc.) it would be a clear winner. But it's not - it's £350, which put's it way beyond the price bracket of 'Hobby'machines. In that price range you are looking at bigger, wheeled mounted machines which have a large gas cylinder carrier on the rear etc.

The Clarke 175TE is a similar price & is a cracking little set. OK it doesn't have a euro-torch, but internally it has a slightly better spec. (namely an industrial style Contactor unit), has a better Duty Cycle & is wheel mounted so you can stick your gas cylinder on the rear & move it all easily around the workshop.

I reckon this machine is perfect for light duty On-Site work, such as erecting wrought iron gates & railings etc. It has plenty of punch at the top end so would quite easily put gates & railings together, can be used with flux cored gas-less wire, so no need to hump gas cylinders around, & is very compact & portable to chuck in the back of the van.

As an automotive/DIY machine, there is better value for money.

All in my humble opinion of course.

weldequip

) - and if you do you should turn the gas on a bit more to avoid the brown mess around your tacks. Can sell you a nice mask if you're having trouble seeing the join to the right of the first photo).

) - and if you do you should turn the gas on a bit more to avoid the brown mess around your tacks. Can sell you a nice mask if you're having trouble seeing the join to the right of the first photo).