- Forums

- Tools, Compressors and Metal Coatings

- Tools, Materials and Techniques

- Home Made Tools and Equipment

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building a CNC Lathe

- Thread starter northwest

- Start date

Dev

8th generation, Weyland type

- Messages

- 1,383

I’m following with great interest, I’d like to do a Clough42 mod as well on a Boxford @Dcal is sorting for me.I hear you loud and clear but the point I was trying to make is that this belt/pulley profile is very much suited to this application and I will be using this HTD profile on my Clough 42 leadscrew conversion on the Harrison, it is a deep profile and High Torque Drive describes it well. What I am saying is it will not slip, under most any circumstance, getting it taut and removing any backlash a given really.

northwest

Searching for the Holy Grail.........

- Messages

- 6,660

- Location

- Manchester UK

Not sure Al, I was really enjoying the journey. It was very good really, I was having good memories of driving up two years ago and collecting George (my Afghan) and seeing @addjunkie s Alpacas so it was a great time remembered. This trip is proving memorable too, I have been welcomed at another forum member's home and his father and I have pretty much fixed the world now.

I am very much looking forward to today and I will get up shortly and find some breakfast and set off.

I am very much looking forward to today and I will get up shortly and find some breakfast and set off.

northwest

Searching for the Holy Grail.........

- Messages

- 6,660

- Location

- Manchester UK

I’m following with great interest, I’d like to do a Clough42 mod as well on a Boxford @Dcal is sorting for me.

Well, expect a new thread very soon beginning Clough42 mod! I bought two of these 2 horse Servos and controllers and I am going to do the conversion on my Harrison, I have had all the bits for a while now. I just needed some advice on the Pulleys and drive belts. The advice on the pulley is 1:1 ratio (I know I would have been in the deep doo doo if I had tried anything else and the profile is HTD. 1:1 for the simple reason I want to use the encoder on the motor and not a separate unit.

addjunkie

Member

- Messages

- 14,289

- Location

- Northumberland. Reet oot in the sticks

You must be getting old, that was more than two years ago…..Not sure Al, I was really enjoying the journey. It was very good really, I was having good memories of driving up two years ago and collecting George (my Afghan) and seeing @addjunkie s Alpacas so it was a great time remembered. This trip is proving memorable too, I have been welcomed at another forum member's home and his father and I have pretty much fixed the world now.

I am very much looking forward to today and I will get up shortly and find some breakfast and set off.

What you doing up there long range bullet bell ringing?

northwest

Searching for the Holy Grail.........

- Messages

- 6,660

- Location

- Manchester UK

IT WORKS, sat for a long while by me it had, but following the ministrations of the incomparable @m_c the dragon breathes fire. Okay, bit OTT that but it spins and whirrs, at high speed too. First I had to fit that bloody pulley, getting on my nerves it was, it was tight too, well it's not going to fall off that's for certain, we are going to need the Tig and a slide hammer if it is:

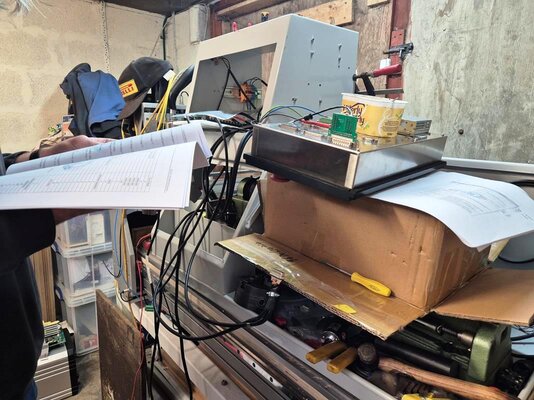

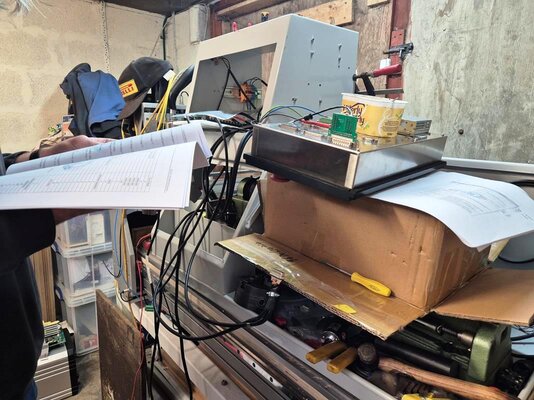

Then the wiring and button pressing began in earnest:

There is a LOT of wire, far more than we needed really.

Then the incantations were recited from the Book_of_Words:

Naturally this awoke the Gods of the dreaded Ladder_Programming (hadn't done this for years and it brought back memories, not all good ones either):

But lo, it whirrs:

Now all I need is an ER 32 collet chuck, a slack handful of ER11 collet chucks and some more D sub breakout boards and I can get rid of my Heath Robinson breakout boards (which must be bad because I was told not to put the pictures up, but it was my contribution and they serve a purpose).

Anyhow tomorrow morning it goes back in the van and It will be taken back to it's place of work, thanks also go to @Hood for coming up with the "default password" which is not in any of the literature! Top man.

Then the wiring and button pressing began in earnest:

There is a LOT of wire, far more than we needed really.

Then the incantations were recited from the Book_of_Words:

Naturally this awoke the Gods of the dreaded Ladder_Programming (hadn't done this for years and it brought back memories, not all good ones either):

But lo, it whirrs:

Now all I need is an ER 32 collet chuck, a slack handful of ER11 collet chucks and some more D sub breakout boards and I can get rid of my Heath Robinson breakout boards (which must be bad because I was told not to put the pictures up, but it was my contribution and they serve a purpose).

Anyhow tomorrow morning it goes back in the van and It will be taken back to it's place of work, thanks also go to @Hood for coming up with the "default password" which is not in any of the literature! Top man.

Breakout boards are the future!

BTW it's a SCSI/MDR connector on the servo, and although I can't find any sensible breakout board for it, you can get this in 36pin form - https://www.aliexpress.com/item/1005007767563983.html which will at least remove the need for soldering!

Getting the spindle servo running was a bit of a challenge, not helped by the first drive either being dead, or due to not having the correct manual for it.

My original plan was to use step/dir control to give the option of using it as a C-axis (the controller also has the option of driving a second spindle, so would give the option of using a sub spindle on the cross slide for doing some fancier stuff), however the parameter instructions given by SZGH support didn't exist in the menu. I'm not sure whether this is due to a firmware change, or whether SZGH sell different levels of this controller with varying functionality.

So more wires were added to run the spindle using 0-10V control, along with a couple wires to select direction.

Everything else was fairly straightforward.

BTW it's a SCSI/MDR connector on the servo, and although I can't find any sensible breakout board for it, you can get this in 36pin form - https://www.aliexpress.com/item/1005007767563983.html which will at least remove the need for soldering!

Getting the spindle servo running was a bit of a challenge, not helped by the first drive either being dead, or due to not having the correct manual for it.

My original plan was to use step/dir control to give the option of using it as a C-axis (the controller also has the option of driving a second spindle, so would give the option of using a sub spindle on the cross slide for doing some fancier stuff), however the parameter instructions given by SZGH support didn't exist in the menu. I'm not sure whether this is due to a firmware change, or whether SZGH sell different levels of this controller with varying functionality.

So more wires were added to run the spindle using 0-10V control, along with a couple wires to select direction.

Everything else was fairly straightforward.

Humbie heading East towards Haddington/Gifford.Trying to think where I’ve seen manicured hedges, near Humbie?

northwest

Searching for the Holy Grail.........

- Messages

- 6,660

- Location

- Manchester UK

Getting the spindle servo running was a bit of a challenge, not helped by the first drive either being dead, or due to not having the correct manual for it.

Mate, I just cannot thank you enough for all of your help, for everyone else: we started at ten in the morning and finished up around seven thirty-ish last night. The plan is to go over this morning and unplug the controller part and dismantle it from the top, put the whole lot in my van and take it home, getting it all back in place and up and running again this week. Then the real work, for me, begins. I will need to learn this controller and is is like giving a chimpanzee an AK47, anything could happen!

I could never have got this working and it was only by sheer luck that I had a spare controller with me, who would have thought to take one with them? I am going to have to get another though as this was earmarked for the Clough42 leadscrew conversion.

northwest

Searching for the Holy Grail.........

- Messages

- 6,660

- Location

- Manchester UK

Well I (we) have now manhandled it back ito place in the "office" part of the workshop. That is quite enough for one day. Tomorrow is another day and you can all look forward to a steady stream of video's/pictures along the lines of "look what I made today" or look what I destroyed today will be more like it! :-)

What I am going to do, in the fullness of time, are a couple of video's on how to set one of these controllers up, I learned more in a brief hour of tutorship by @m_c than I learned in a year if searching out Youtube video's. Absolutely priceless info and now I have a clue as to what it is all about I feel I can progress at pace rather than fighting every inch of the way. Nothing like actually making something, even if it is only half of something for inspiring confidence and keeping enthusiasm alive, the most optimistic person in the world will get discouraged eventually if all you are doing is failing.

What I am going to do, in the fullness of time, are a couple of video's on how to set one of these controllers up, I learned more in a brief hour of tutorship by @m_c than I learned in a year if searching out Youtube video's. Absolutely priceless info and now I have a clue as to what it is all about I feel I can progress at pace rather than fighting every inch of the way. Nothing like actually making something, even if it is only half of something for inspiring confidence and keeping enthusiasm alive, the most optimistic person in the world will get discouraged eventually if all you are doing is failing.

Erie Fred

Member

- Messages

- 6,361

- Location

- Erie, Pa USofA

The belt system he is using is used in several commercial CNC machines in the same application.Any slack in the belt is backlash in the system, which cancels the no-backlash of the ballscrew that it is driving.

You would only notice it if doing a profile operation like a handwheel handle where the cross slide has to go in and out as part of the same cut.

There would be some tolerance in the pulley and (rubber) belt manufacture, so the theoretical centre distance is just that and the manufacturer is doing no-one any favours quoting it to 0.1mm.

northwest

Searching for the Holy Grail.........

- Messages

- 6,660

- Location

- Manchester UK

Today I learned the importance of homing positions. It took me most of the day to "get it" but when I finally did it was a revelation. I couldn't understand what was happening, the machining cycle I was using to practice with wasn't doing today what it was doing yesterday and I just could not understand why. It was only because I sat down and looked at the problem from a different perspective and really looked at it that the penny dropped and I understood what was happening, it was going to where it thought home was first then starting from there instead of where I wanted it to start. This just ain't easy.

northwest

Searching for the Holy Grail.........

- Messages

- 6,660

- Location

- Manchester UK

I need some help guys. I need a 36pin Amphenol SCSI Connector male plug, Don't care where from but I need it here before Monday! Can anyone help me out with a link? I can buy loads from Ali Express but they are taking a minimum of three weeks :-(