Am getting pretty tired of broaching keyways with my manual Chinese press, thinking of making a bracket for a double action hydraulic cylinder which I'll power of the hydraulic pump of my 4 post lift.

I have a 70mm cylinder which will roughly press about 5.6 ton at 200 bar, will this be enough to broach 12mm keyways, I assume it is but am not sure.

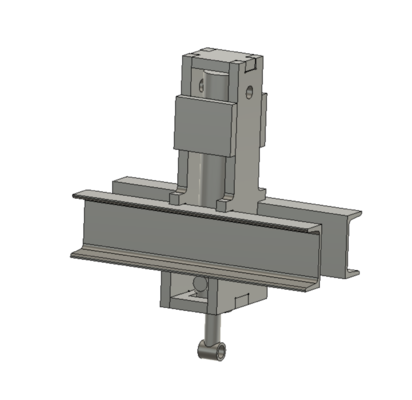

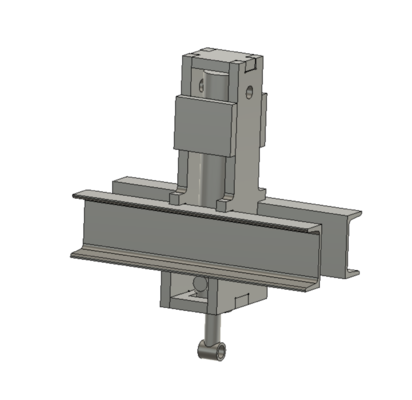

Any remarks about the design below? All made out of 20mm steel plate, it's basically a bracket that holds the piston that hooks onto the 2 existing U channels from the Chinese press.

Thanks Christof.

Type of press:

'Design'

I have a 70mm cylinder which will roughly press about 5.6 ton at 200 bar, will this be enough to broach 12mm keyways, I assume it is but am not sure.

Any remarks about the design below? All made out of 20mm steel plate, it's basically a bracket that holds the piston that hooks onto the 2 existing U channels from the Chinese press.

Thanks Christof.

Type of press:

'Design'

, I'm just a one guy side business 'shop' no budget and room for a dedicated press. So will probably go against advice and try it with the hydraulic piston.

, I'm just a one guy side business 'shop' no budget and room for a dedicated press. So will probably go against advice and try it with the hydraulic piston.