Hi all

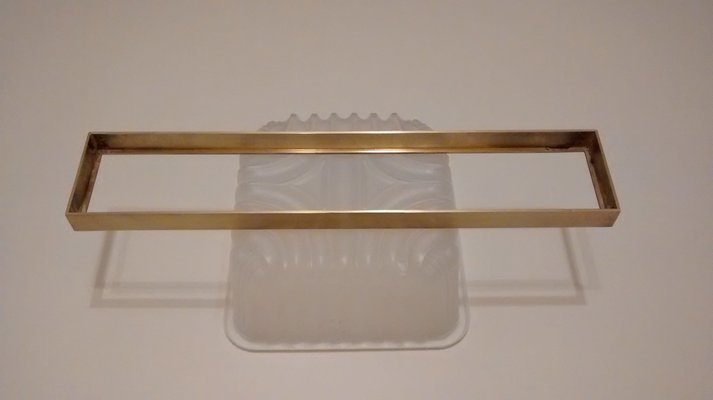

I'm working for a shop fitting company. every now and then we get Some 25x25x2 angle brass frames. Some of them are over 1.5m squared they can be really flimsy, i've had a couple of them come back from the polishers cracked.

I'm also having problems with porosity, i end up wasting too much time grinding and filling pin holes.

The way we are expected to do it is to tig weld it with regular brass filler, but the second i get a pool the zinc starts burning out of the metal,I get white soot over everything and spatter all over my tungsten. there must be a better way to do it.

I have thought about using silicon bronze filler and brazing it, but will it be strong enough? and will it show when mirror polished?

Any advice is appreciated

I'm working for a shop fitting company. every now and then we get Some 25x25x2 angle brass frames. Some of them are over 1.5m squared they can be really flimsy, i've had a couple of them come back from the polishers cracked.

I'm also having problems with porosity, i end up wasting too much time grinding and filling pin holes.

The way we are expected to do it is to tig weld it with regular brass filler, but the second i get a pool the zinc starts burning out of the metal,I get white soot over everything and spatter all over my tungsten. there must be a better way to do it.

I have thought about using silicon bronze filler and brazing it, but will it be strong enough? and will it show when mirror polished?

Any advice is appreciated