You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

bender recomendations

- Thread starter dannyp

- Start date

It'd also be worth having a play with card templates etc next time you're playing with exhaust stuff. If you're currently using hygienic bends they are typically 1.5D or 2D CLR compared with 3 - 3 1/2D minimum for 'straight' rotary draw bends

Sand bending can work but is pretty labour intensive and not necessarily straightforward/easy. My mate had a play with sandbending in his kit and the first experiments didn't end well... hydraulic pressure is one of the main variables with his kit, my thoughts being that he'd need to experiment. He couldn't be bothered and stuck with buying mandrel bends when necessary. As Shox said there are fusible alloys and resins available for use with machine bending but i think typically used with smaller diameter stuff. They should be a bit less labour intensive than sand but then they cost more. This place claims to use sand bending with a Pearson press bender for 'one offs' alongside cnc mandrel bent production work... http://www.quicksilverexhausts.com/technology.asp

Also found this guide showing suggested set ups for different wall factors and CLR which gives an idea of the type of set up commercially available bends are made with... http://pdf.directindustry.com/pdf/addisonmckee/tube-bending-guide-poster/Show/33286-57605.html

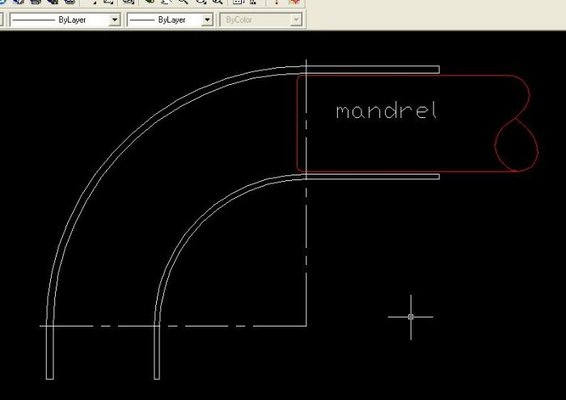

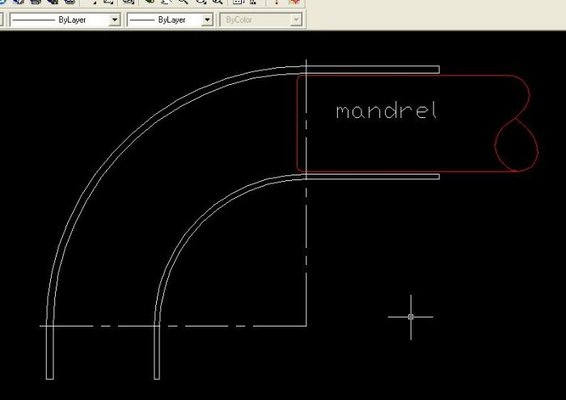

Basic 'plug mandrels' are pretty simple in principle and should extend the capabilities of a rotary draw machine a lttle, probably more so with smaller diameters. How far you could reduce CLR with 2 1/2 - 3" tube is another question and of course there's the availablity/cost of dies. They work on two fronts and their effect depends some on where the mandrel is in relation to the bend tangent...

Note the mandrel is sitting slightly past the bend tangent, probably not far enough in my drawing. The mandrel forces the tube into the pressure die (outside of bend) and bend die (inside of bend) i.e. the tube is made to stretch more at the outer radius of the bend which reduces flattening while the mandrel prevents the inner radius from wrinkling as it enters the bend die. If the mandrel is too far forward you get humps/bumps on the tube at the bend tangents, too far back and you get wrinkles on the ID, the OD may flatten and because the OD isn't stretched enough to maintain it's profile increased springback as the outside of the bend remains in tension

I wouldn't have thought mandrel extraction should be a big issue as small hand powered versions exist. Mandrel remains static on a long adjustable draw bar and is typically aluminium bronze or a nickel Albronze for stainless. Google pic of a 'form' plug mandrel here

Sand bending can work but is pretty labour intensive and not necessarily straightforward/easy. My mate had a play with sandbending in his kit and the first experiments didn't end well... hydraulic pressure is one of the main variables with his kit, my thoughts being that he'd need to experiment. He couldn't be bothered and stuck with buying mandrel bends when necessary. As Shox said there are fusible alloys and resins available for use with machine bending but i think typically used with smaller diameter stuff. They should be a bit less labour intensive than sand but then they cost more. This place claims to use sand bending with a Pearson press bender for 'one offs' alongside cnc mandrel bent production work... http://www.quicksilverexhausts.com/technology.asp

Also found this guide showing suggested set ups for different wall factors and CLR which gives an idea of the type of set up commercially available bends are made with... http://pdf.directindustry.com/pdf/addisonmckee/tube-bending-guide-poster/Show/33286-57605.html

Basic 'plug mandrels' are pretty simple in principle and should extend the capabilities of a rotary draw machine a lttle, probably more so with smaller diameters. How far you could reduce CLR with 2 1/2 - 3" tube is another question and of course there's the availablity/cost of dies. They work on two fronts and their effect depends some on where the mandrel is in relation to the bend tangent...

Note the mandrel is sitting slightly past the bend tangent, probably not far enough in my drawing. The mandrel forces the tube into the pressure die (outside of bend) and bend die (inside of bend) i.e. the tube is made to stretch more at the outer radius of the bend which reduces flattening while the mandrel prevents the inner radius from wrinkling as it enters the bend die. If the mandrel is too far forward you get humps/bumps on the tube at the bend tangents, too far back and you get wrinkles on the ID, the OD may flatten and because the OD isn't stretched enough to maintain it's profile increased springback as the outside of the bend remains in tension

I wouldn't have thought mandrel extraction should be a big issue as small hand powered versions exist. Mandrel remains static on a long adjustable draw bar and is typically aluminium bronze or a nickel Albronze for stainless. Google pic of a 'form' plug mandrel here