BarrieJ

Member

- Messages

- 884

- Location

- Milton Keynes, Bucks, United Kingdom

I recently saved this bench drill from the scrap yard, it’s in a bit of a state and following the recent death of my wife, the distraction of a project is very welcome.

So, I’d like to restore it to a serviceable condition.

When found, the motor had been dumped separately and was only temporarily reattached for the photographs, hence it appearing a little out of the vertical.

With the motor in position, the whole is physically too heavy for me to lift.

The capacitor housing has taken a bump; I suspect when the motor was dumped into the skip, despite this, it still starts and runs.

The drill is obviously of an industrial nature, it’s incredibly heavy, heavier than my old Fobco Star, which I could lift. The 3” dia column is solid steel and the rest cast iron, including the belt cover.

I doubt the Brooks’ 240 volt, 1 h.p. motor is original but the motor starter switch appears to be of a similar vintage to the drill.

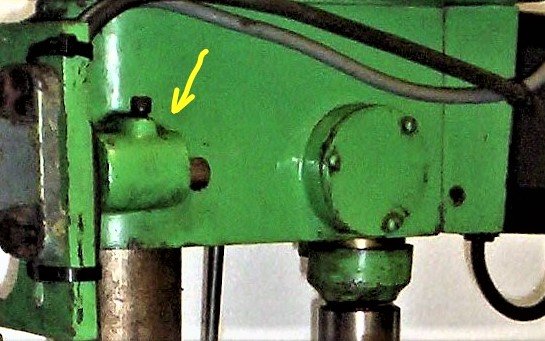

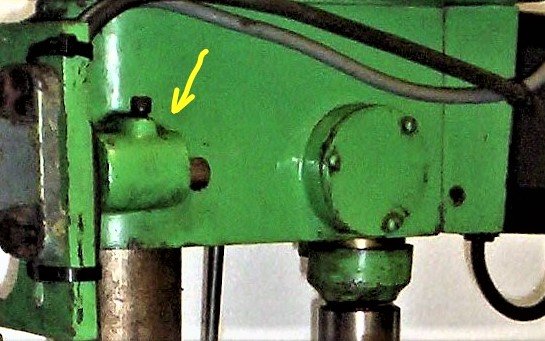

There was play in the quill but I have adjusted that, courtesy of a pinch bolt in the head, (a rare feature absent in cheap imported drills) there didn’t appear to be much play in the spindle; odd because much of the rest of the drill is quite worn. If there turns out to be, then I suspect a change of bearings will be required.

What I’m struggling with is identifying the maker. Nowhere can I find any clue, there’s no casting marks, nothing under the base or under the belt cover. The drill has several features shared with other manufacturers but together in one drill seem to be almost unique. All fastenings are imperial.

The locking motor mounting bolts at the rear of the head; allowing for belt adjustment. These are normally tapped horizontally into a drill’s head casting, facing the operator. Here, they’re vertical bearing down on the motor mount pins. The drive belt cover is cast iron; it doesn't hinge or pop up, you have to lift it off to change speeds.

The drilling table is unusually small for a machine of this size, The tables on my old Pollard 12AX and my current Fobco 7/Eights were and are almost double the size. It also has a trough or gutter running around the perimeter which in an industrial setting often have a plumbed outlet allowing waste coolant to be recycled back into a reservoir. Here there’s no outlet, coolant and swarf collect in the trough.

There’s an original fitted rack and pinion which is so worn as to be barely functional. Predictably it’s the pinion and associated bevel gear that has suffered the most. This might be a bit of a challenge to replace but we’ll see.

The column at 3” diameter is larger than modern imported versions, so no chance of swapping the rack and pinion with one from a Sealey/Clarke/Naerok/Rexon/etc., clone.

Similarly the quill feed handle socket is either badly worn or off another machine and will need to be slightly overbored and a bush turned and pressed into it. Fortunately, quite straightforward.

Most unique of all; albeit in my limited experience, is the base which has no bolt holes allowing it to be fastened to a bench top or machine stand, instead, two machined ‘T’ slots, running laterally, one front and one rear. I have never come across that before on a drill.

The drill itself is quite top heavy and in use I'd definitely want to utilise 'T' bolts to secure it.

I’ve checked as many online sources as I can (Google constantly wanting to sell me drills is an irritation) but I can’t find any drill that comes close; some have similar rack and pinions, some have small square tables but none have bases featuring 'T' slots.

I don't think not knowing will prevent me bringing this back to life but for the sake of curiosity it would be nice to know who made it.

Any help from the communal hive of expertise would be much appreciated.

So, I’d like to restore it to a serviceable condition.

When found, the motor had been dumped separately and was only temporarily reattached for the photographs, hence it appearing a little out of the vertical.

With the motor in position, the whole is physically too heavy for me to lift.

The capacitor housing has taken a bump; I suspect when the motor was dumped into the skip, despite this, it still starts and runs.

The drill is obviously of an industrial nature, it’s incredibly heavy, heavier than my old Fobco Star, which I could lift. The 3” dia column is solid steel and the rest cast iron, including the belt cover.

I doubt the Brooks’ 240 volt, 1 h.p. motor is original but the motor starter switch appears to be of a similar vintage to the drill.

There was play in the quill but I have adjusted that, courtesy of a pinch bolt in the head, (a rare feature absent in cheap imported drills) there didn’t appear to be much play in the spindle; odd because much of the rest of the drill is quite worn. If there turns out to be, then I suspect a change of bearings will be required.

What I’m struggling with is identifying the maker. Nowhere can I find any clue, there’s no casting marks, nothing under the base or under the belt cover. The drill has several features shared with other manufacturers but together in one drill seem to be almost unique. All fastenings are imperial.

The locking motor mounting bolts at the rear of the head; allowing for belt adjustment. These are normally tapped horizontally into a drill’s head casting, facing the operator. Here, they’re vertical bearing down on the motor mount pins. The drive belt cover is cast iron; it doesn't hinge or pop up, you have to lift it off to change speeds.

The drilling table is unusually small for a machine of this size, The tables on my old Pollard 12AX and my current Fobco 7/Eights were and are almost double the size. It also has a trough or gutter running around the perimeter which in an industrial setting often have a plumbed outlet allowing waste coolant to be recycled back into a reservoir. Here there’s no outlet, coolant and swarf collect in the trough.

There’s an original fitted rack and pinion which is so worn as to be barely functional. Predictably it’s the pinion and associated bevel gear that has suffered the most. This might be a bit of a challenge to replace but we’ll see.

The column at 3” diameter is larger than modern imported versions, so no chance of swapping the rack and pinion with one from a Sealey/Clarke/Naerok/Rexon/etc., clone.

Similarly the quill feed handle socket is either badly worn or off another machine and will need to be slightly overbored and a bush turned and pressed into it. Fortunately, quite straightforward.

Most unique of all; albeit in my limited experience, is the base which has no bolt holes allowing it to be fastened to a bench top or machine stand, instead, two machined ‘T’ slots, running laterally, one front and one rear. I have never come across that before on a drill.

The drill itself is quite top heavy and in use I'd definitely want to utilise 'T' bolts to secure it.

I’ve checked as many online sources as I can (Google constantly wanting to sell me drills is an irritation) but I can’t find any drill that comes close; some have similar rack and pinions, some have small square tables but none have bases featuring 'T' slots.

I don't think not knowing will prevent me bringing this back to life but for the sake of curiosity it would be nice to know who made it.

Any help from the communal hive of expertise would be much appreciated.