conor1n

Member

- Messages

- 556

- Location

- London/Ireland

Evening all,

It took a while..... as part of by new business i've been working on setting up all manner of things, and getting distracted on a few other things.

But in a nutshell, I had to build a space where I can attempt to contain dust, buy and install my screw compressor, modify my chinese special blasting pot, trouble shoot my compressor. Woah, when I say it one sentence like that it seems trivial, but man, doing stuff on your own and running around to get various parts etc (sometimes in another town) really takes a chunk out of your time.

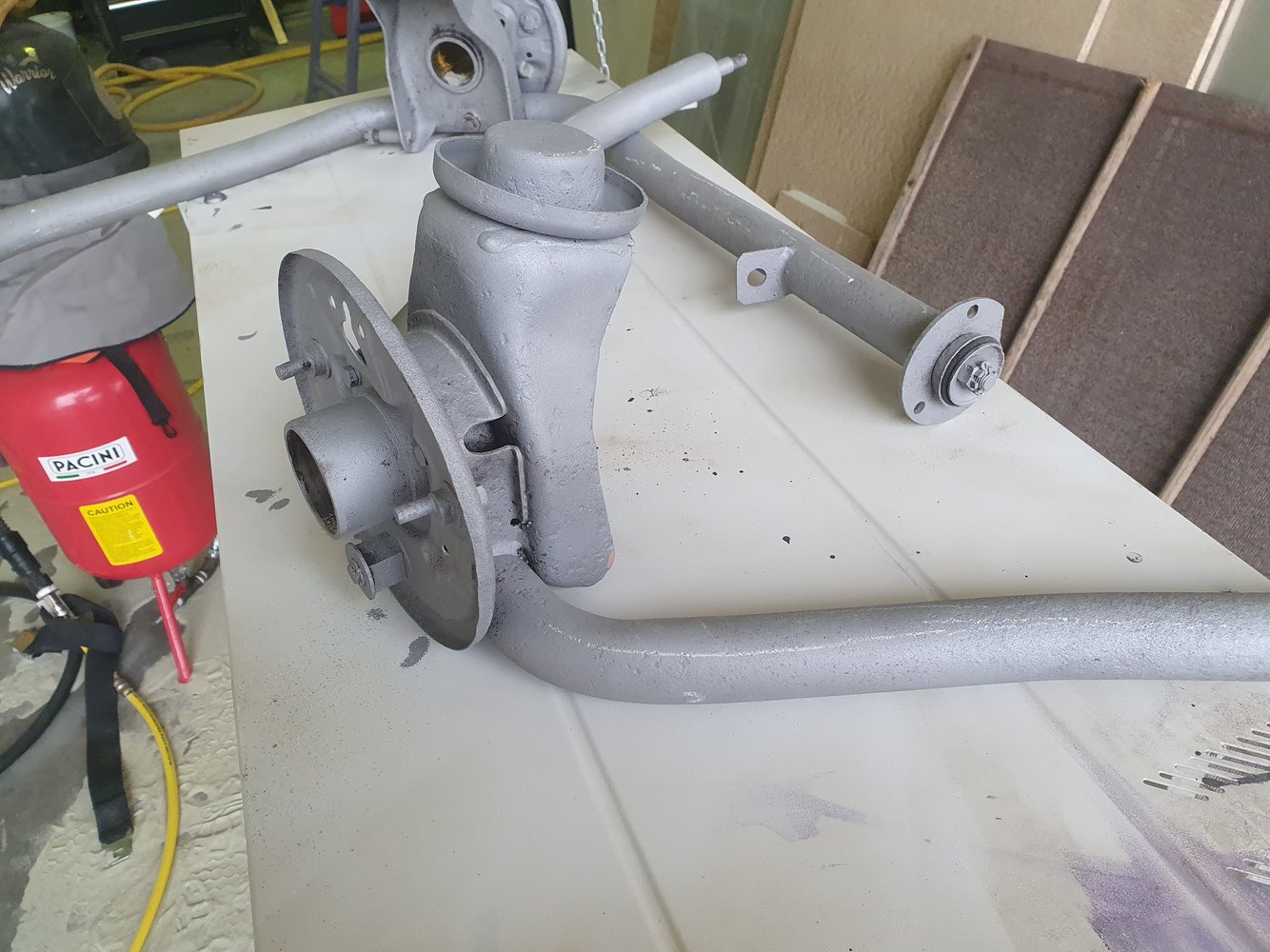

But anyway... here is my first project for somebody who is not me. It's brake shoes and half axles from an old NSU that a guy is contributing work to for the NSU Club in Ireland.

I am very happy with the result... blasting is a major faff, but I can get my process dialled in. I have decided when it comes to parts lile this etc, I am only going to do them once a week. Due to setup and stuff etc. If it makes sense later on, I will get one of those larger blast cabinets that should accommodate much larger parts.

I must admit that I painted the brake shoes in etch primer + base coat, but the axles are done in Rustbuster EM121, which I believe is actually Jotun Jotamastic Smart Pack.

I have one coat down on the axles and will give it a second coat tomorrow. It's good and bad that the overcoat times are long, as are the max times and ready for active use. It means you don't need to rush.. but it does mean that I don't need to stay late into the evening to get a second coat in, like I did with regular paint when doing my car.

Interested to hear what you think. I would call this SA 3 in the vast majority of the axle, but I believe SA 2 is suitable for Jotun products. So going forward I probably won't be as anal on that front.

I'm still building marketing material though and SA3 certainly looks much better on that front, I think.

It took a while..... as part of by new business i've been working on setting up all manner of things, and getting distracted on a few other things.

But in a nutshell, I had to build a space where I can attempt to contain dust, buy and install my screw compressor, modify my chinese special blasting pot, trouble shoot my compressor. Woah, when I say it one sentence like that it seems trivial, but man, doing stuff on your own and running around to get various parts etc (sometimes in another town) really takes a chunk out of your time.

But anyway... here is my first project for somebody who is not me. It's brake shoes and half axles from an old NSU that a guy is contributing work to for the NSU Club in Ireland.

I am very happy with the result... blasting is a major faff, but I can get my process dialled in. I have decided when it comes to parts lile this etc, I am only going to do them once a week. Due to setup and stuff etc. If it makes sense later on, I will get one of those larger blast cabinets that should accommodate much larger parts.

I must admit that I painted the brake shoes in etch primer + base coat, but the axles are done in Rustbuster EM121, which I believe is actually Jotun Jotamastic Smart Pack.

I have one coat down on the axles and will give it a second coat tomorrow. It's good and bad that the overcoat times are long, as are the max times and ready for active use. It means you don't need to rush.. but it does mean that I don't need to stay late into the evening to get a second coat in, like I did with regular paint when doing my car.

Interested to hear what you think. I would call this SA 3 in the vast majority of the axle, but I believe SA 2 is suitable for Jotun products. So going forward I probably won't be as anal on that front.

I'm still building marketing material though and SA3 certainly looks much better on that front, I think.