I'm trying to learn to TIG Aluminium but am struggling with most everything. Previous experience was just MIG on steel. In particular, when running a long bead, say 2 inches (50 mm), everything gets really hot such that even when adding filler rod, I can create a trench. I try backing off on the pedal but am not being very successful at keeping things in control. The weld puddle can get really wide and everything starts to happen very fast. Could this be normal or expected? I also wonder if I let the arc gap get larger or possible lean the torch too much but don't know how to gage these. Are there any tricks, guidelines or recommendations? I tried to video with a gopro but it looks like I would need some kind of filter to see what is going on.

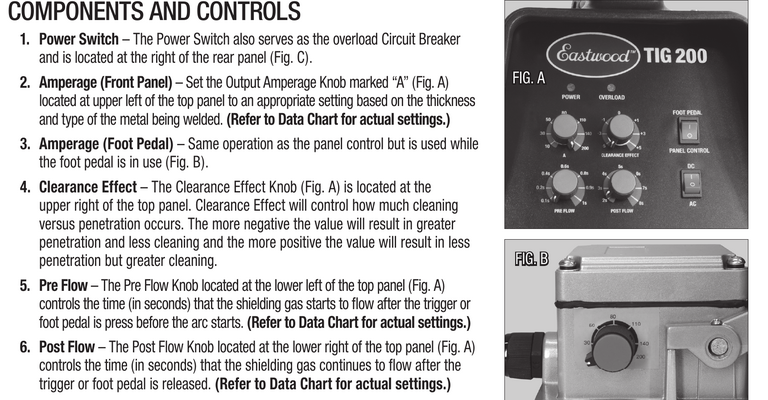

The machine is an Eastwood AC/ DC 200 and besides amps, the only arc adjustment is ballance which is set at -3. Im practicing on 3/16 (4.7 mm) 5052 aluminium using 3/32" (2.4 mm) 4043 rod. I'm using blue 3/32 tungsten set around 180 amps.

The machine is an Eastwood AC/ DC 200 and besides amps, the only arc adjustment is ballance which is set at -3. Im practicing on 3/16 (4.7 mm) 5052 aluminium using 3/32" (2.4 mm) 4043 rod. I'm using blue 3/32 tungsten set around 180 amps.