mtt.tr

Member

- Messages

- 8,454

- Location

- Essex/Suffolk border

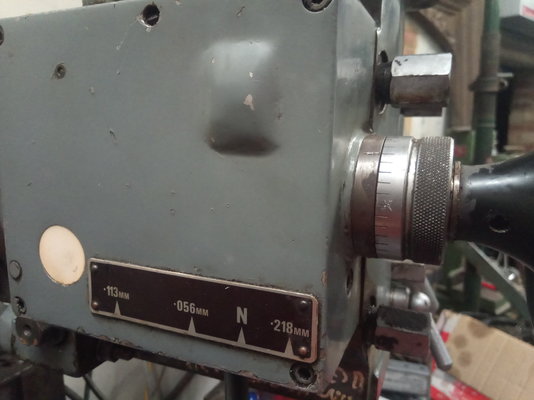

Im making some progress in getting the mill rewired. But something that tickled me Is the fine spindle feed per full rotation drops the spindle 3.8mm

But the dial has 39 segments equating to 0.097mm per segment thought i was losing the plot

So at some point i will make abother feed dial.

But the dial has 39 segments equating to 0.097mm per segment thought i was losing the plot

So at some point i will make abother feed dial.