Paul, get yourself a good length of hexagonal stock bar, a decent sized hammer lump / sledge, heat the axle tube around the bearing track area and Robert's your mothers brother, or alternatively a length of tube, eg. scaffold or round solid stock that is slightly smaller in diameter than the id of the axle tube so that it slides inside and use the same method, the beauty of using the tube method is you have a full 360% bearing on the backside of the track and therefore will be knocking it out square as opposed to at an angle. simples....

Do you mean heat the outside of the axle and then tap it to loosen if off inside ? If so where does the hexagonal bar come into play ?

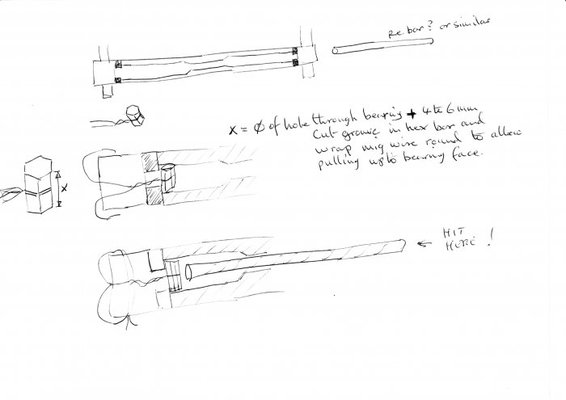

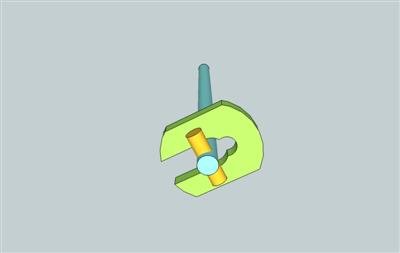

This is what im trying to get out :