Sharp Tungsten

Member

- Messages

- 5

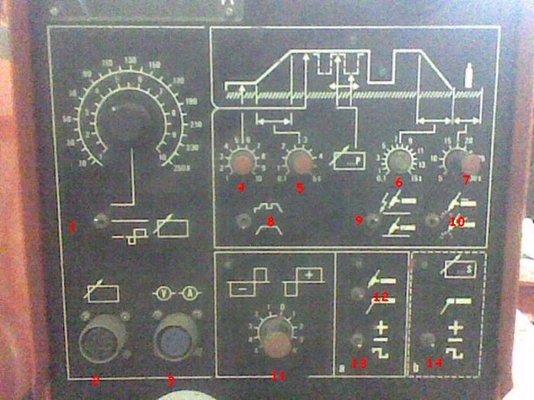

Sorry Archie I forgot to say that my kemppi is identical to the one pictured. That is why i was excited to see it on here and joined the form. I have seen Flange Jockey on several U.S websites and always enjoy looking at his beautiful welds. Thank you for your time Archie

And I have a Lincoln myself so they can't be all bad!

And I have a Lincoln myself so they can't be all bad!

Now I need more scrap and more practise!

Now I need more scrap and more practise!