Pollys13

Member

- Messages

- 377

- Location

- Wiltshire UK

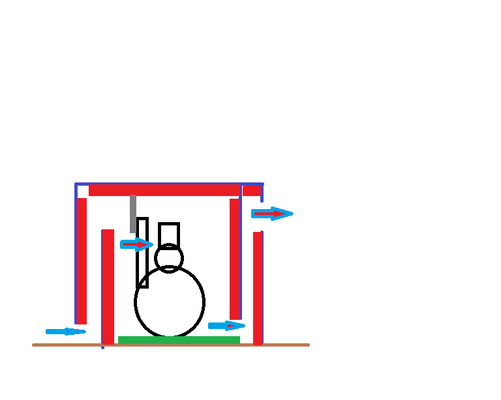

I have a Wolf 90 litre compressor like this one, Ebay item number Bay item number: 372225303961. Even though is belt driven is still quite noisy I'd like to reduce this. I've had a look around but can't really find anything I thought was suitable. I was thinking of say MDF box lined with sound insulating tiles, with PC fan to prevent heat build up no base as could lift up and place over compressor, compressor would be rested on some rubber carpet tiles. This morning I was thinking of an actual enclosed box, on castors, contrive some type of flap so could move compressor into box.

I also have a Cyclone upright DC-1500 Dust Collector, see https://www.cycloneblasters.com/product/blast-cabinet-dust-collector/

This is also quite noisy and I would like to make some type of enclousure for it

I also have a Cyclone upright DC-1500 Dust Collector, see https://www.cycloneblasters.com/product/blast-cabinet-dust-collector/

This is also quite noisy and I would like to make some type of enclousure for it