Endacy

Member

- Messages

- 278

scarecrow: thanks for the nice comments about my truck! That rope is actually a bridle which I use to link to the two front recovery points, it's ex military. My shackles are just as stupidly big (a few kg each!), always better safe than sorry.

rtbcomp: Yes it would suggest it was UK made but then again everyone outsources so that's probably a red herring.

Alex: yes stainless is nice, but not for this - I understand it work hardens and snaps. How ironic.

TechnicAL: I think your comment about a 'material weaker than required' is probably about right.

malcolm: catastrophic failure is 'usually' something parts are designed to avoid? I like it!

The aftermarket suppliers of Land Rover parts all redesign things on the cheap. For example brake wheel cylinders are often made from steel which when you consider brake fluid is hygroscopic isn't a very bright idea. I will only ever fit genuine Lucas Girling cylinders, all the others fail too quickly. The steel ones are sometimes even marketed as 'stronger' than the alloy ones - what a useful feature, ever smashed a wheel cylinder? No?

Another example is kingpins whose corresponding railko bushes are so undersize I suspect the machining isn't finished. Exhausts made paper thin, a good one should last about 3 years before it begins to fail, a cheap one for me did 9 months before complete and utter disintegration. The list goes on!

Anyway have some more pictures!

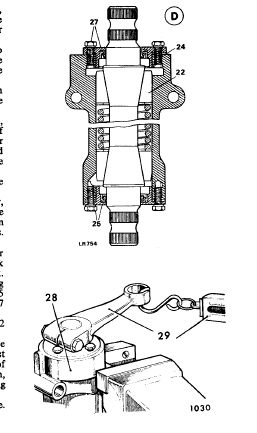

The shaft left in the unit:

The bit that broke off from different angles, it shows what to me is an origin of the failure? Ignore the rust and dirt, this has been on the floor! The joint was all grey before I covered it in cr*p.

Some bits clearly fell off leaving gaps when you place it back where is was:

And for reference here is the end of an (also grubby) halfshaft which I killed, these are a piece of steel machined and turned to create a shaft, the failure is more of a shattering effect when these go. You can often reassmble the bits like a jigsaw. This one was an odd failure, it failed at the outboard (wheel) end, I suspect as it was a pattern part the machining was poor. It was a welcome surprise though, they normally break inside the differential and that requires stripping the axle down

rtbcomp: Yes it would suggest it was UK made but then again everyone outsources so that's probably a red herring.

Alex: yes stainless is nice, but not for this - I understand it work hardens and snaps. How ironic.

TechnicAL: I think your comment about a 'material weaker than required' is probably about right.

malcolm: catastrophic failure is 'usually' something parts are designed to avoid? I like it!

The aftermarket suppliers of Land Rover parts all redesign things on the cheap. For example brake wheel cylinders are often made from steel which when you consider brake fluid is hygroscopic isn't a very bright idea. I will only ever fit genuine Lucas Girling cylinders, all the others fail too quickly. The steel ones are sometimes even marketed as 'stronger' than the alloy ones - what a useful feature, ever smashed a wheel cylinder? No?

Another example is kingpins whose corresponding railko bushes are so undersize I suspect the machining isn't finished. Exhausts made paper thin, a good one should last about 3 years before it begins to fail, a cheap one for me did 9 months before complete and utter disintegration. The list goes on!

Anyway have some more pictures!

The shaft left in the unit:

The bit that broke off from different angles, it shows what to me is an origin of the failure? Ignore the rust and dirt, this has been on the floor! The joint was all grey before I covered it in cr*p.

Some bits clearly fell off leaving gaps when you place it back where is was:

And for reference here is the end of an (also grubby) halfshaft which I killed, these are a piece of steel machined and turned to create a shaft, the failure is more of a shattering effect when these go. You can often reassmble the bits like a jigsaw. This one was an odd failure, it failed at the outboard (wheel) end, I suspect as it was a pattern part the machining was poor. It was a welcome surprise though, they normally break inside the differential and that requires stripping the axle down

someone else bumped it - honest guv

someone else bumped it - honest guv