Brad93

Member

- Messages

- 19,085

- Location

- Essex, United Kingdom

I’m having trouble with another thread.

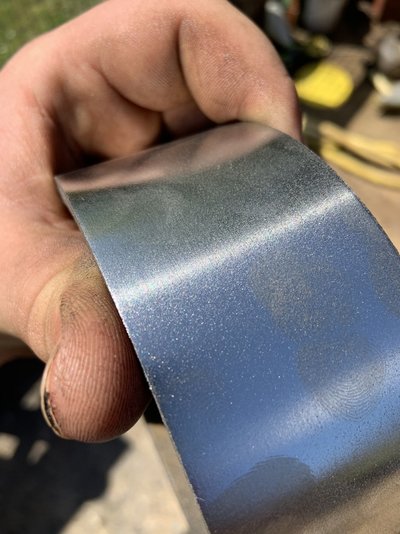

I’ve used a better quality steel, threading at 305rpm now, got a nice thread.

I am trying to thread, M20 x 2.5mm pitch.

My OD started at 20.06.

My OD is now 19.88 and my threads are the full depth of the 2.5mm insert.

I still can’t get a nut on?

Any ideas?

I’ve used a better quality steel, threading at 305rpm now, got a nice thread.

I am trying to thread, M20 x 2.5mm pitch.

My OD started at 20.06.

My OD is now 19.88 and my threads are the full depth of the 2.5mm insert.

I still can’t get a nut on?

Any ideas?