stanbester

Member

- Messages

- 101

- Location

- United Kingdom West Yorkshire Halifax

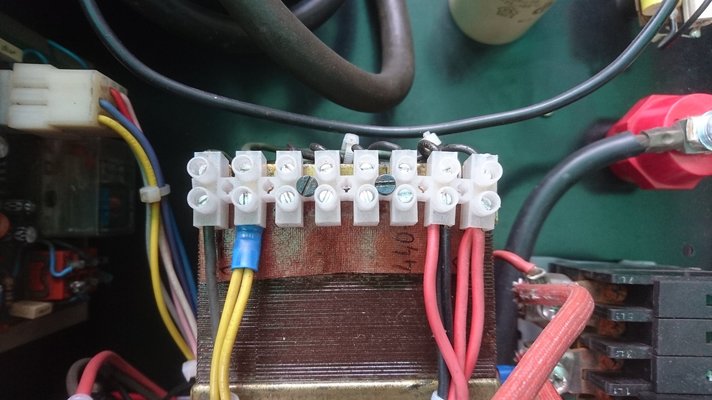

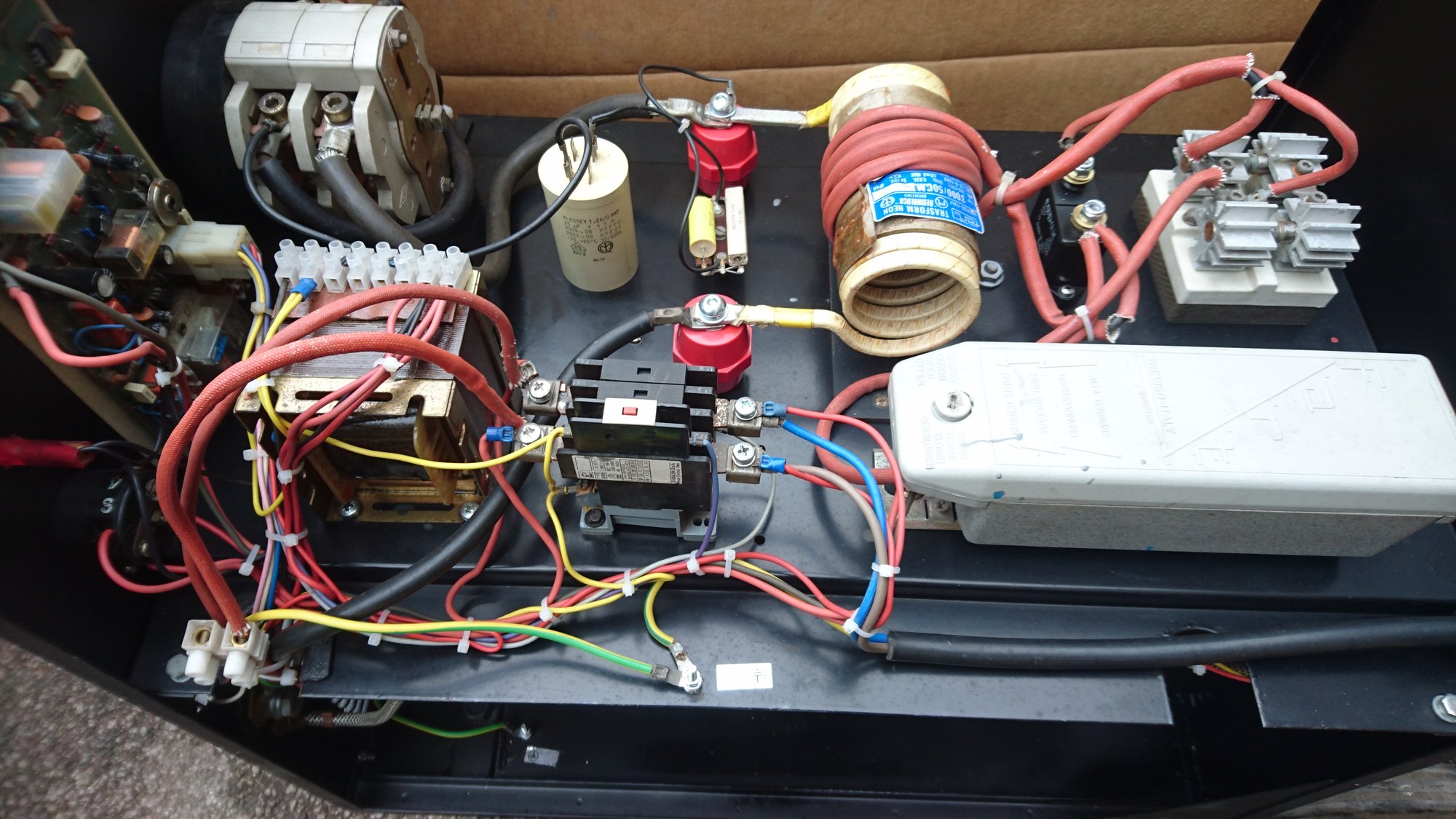

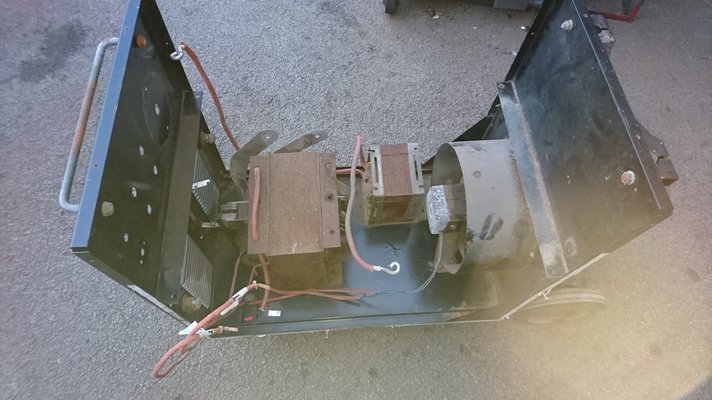

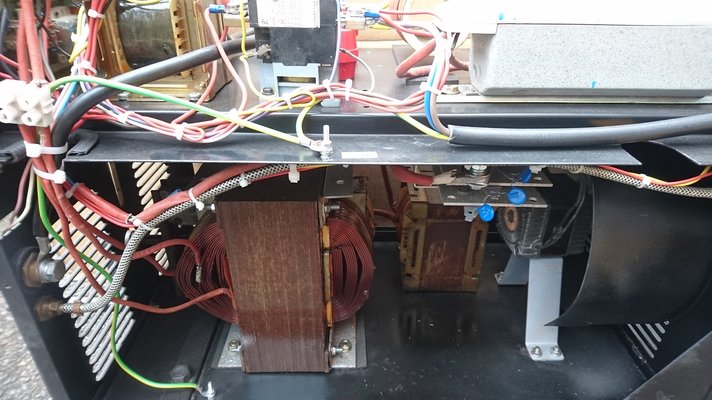

About two years ago I bought Cebora tig welder. Came with side panels and top missing, bit of dirt and rust here and there, no earth or electrode holder leads. It was designed to be powered by two phases 440v so first thing I did was to convert it to 240v as I haven't got three phase power supply and it works perfect. Next step was taking it apart then cleaning, redoing all vital connections. Now everything is back together, meanwhile had new panels made and just waiting for them to be powdercoated.

Here's a few photos

Here's a few photos

or was it migatronic??

or was it migatronic??