Hi, i'm new to the forum, and to welding. I just bought a Clark 151TE, for general use mostly working on cars and general littel bits of fabrication.

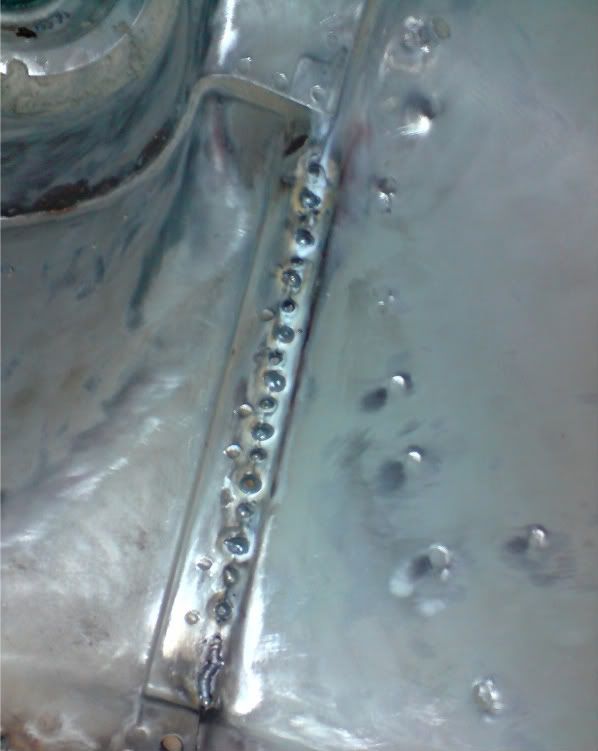

The main reason i picked up a MIG now is that i'm restoring an old audi coupe quattro and wanted to seam weld the chassis for extra torsional strength.

I read the tutorials on here (bvery useful ) and I practiced quite a bit on overlap joints with 0.8mm steel and after a while was getting pretty decent penetration and reasonably tidy welds - this was on lowest power setting and just over 5 (1- 10 scale on the knob) on the wire speed.

) and I practiced quite a bit on overlap joints with 0.8mm steel and after a while was getting pretty decent penetration and reasonably tidy welds - this was on lowest power setting and just over 5 (1- 10 scale on the knob) on the wire speed.

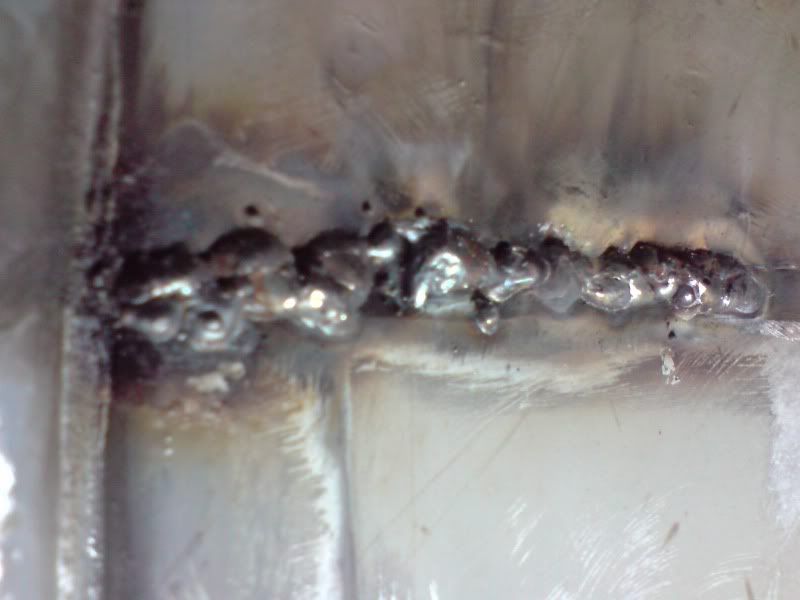

As soon as I went onto the car however, I couldn't get any decent penetration and the weld was building up on the surface and looking very snotty. As I was welding too, it was spitting badly. I know the panels on the car were galvanised from the factory, and I have wire brushed and gently grinded the joints back to bare metal, but it made no real difference - still spitting badly and not gettting decent penetration. I tried to weld slower and make the wled pool bigger but it just built up on the surface.

I went back to the 0.8 steel I was practising on and could weld ok again.

So I tried upping the power onto the second setting from bottom to get better penetration on the car body welds but it just started to blow away the top sheet on the overlap joint.

Have any of you experenced folk got any suggestions?

The main reason i picked up a MIG now is that i'm restoring an old audi coupe quattro and wanted to seam weld the chassis for extra torsional strength.

I read the tutorials on here (bvery useful

) and I practiced quite a bit on overlap joints with 0.8mm steel and after a while was getting pretty decent penetration and reasonably tidy welds - this was on lowest power setting and just over 5 (1- 10 scale on the knob) on the wire speed.

) and I practiced quite a bit on overlap joints with 0.8mm steel and after a while was getting pretty decent penetration and reasonably tidy welds - this was on lowest power setting and just over 5 (1- 10 scale on the knob) on the wire speed. As soon as I went onto the car however, I couldn't get any decent penetration and the weld was building up on the surface and looking very snotty. As I was welding too, it was spitting badly. I know the panels on the car were galvanised from the factory, and I have wire brushed and gently grinded the joints back to bare metal, but it made no real difference - still spitting badly and not gettting decent penetration. I tried to weld slower and make the wled pool bigger but it just built up on the surface.

I went back to the 0.8 steel I was practising on and could weld ok again.

So I tried upping the power onto the second setting from bottom to get better penetration on the car body welds but it just started to blow away the top sheet on the overlap joint.

Have any of you experenced folk got any suggestions?