Hi,

I have come on this site to try and help my local garage, who are doing some work for me, when I mentioned that my background is electrical/electronic engineering (now retired) and he asked if I might know what was wrong with this welder. Well, it's a bit of a specialized area, but hope someone might have come across the fault.

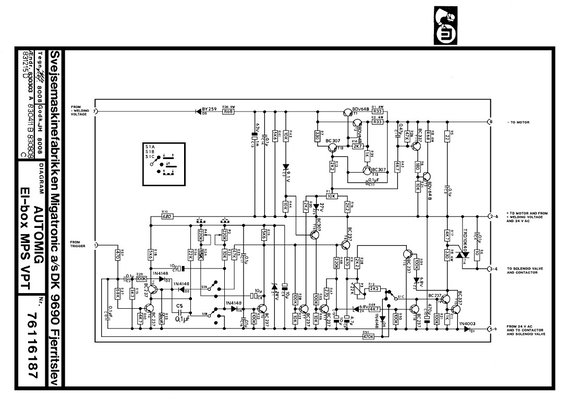

The unit works ok, but he tells me that the gas contactor (relay) suffers from quite bad arcing. I suggested that cleaning the contacts (if this is possible-I've not seen inside the welder) might help. I also see on a circuit for another welder (180 MXE) of the same make (could not find a circuit for the 5000 MX model on line) has a bridge of capacitors, but it looks like these are not to protect the contacts but in fact power factor correction.

Maybe the contactor/relay simply needs replacing?

Any help or advice will be appreciated and passed on.

Many thanks, Rod

I have come on this site to try and help my local garage, who are doing some work for me, when I mentioned that my background is electrical/electronic engineering (now retired) and he asked if I might know what was wrong with this welder. Well, it's a bit of a specialized area, but hope someone might have come across the fault.

The unit works ok, but he tells me that the gas contactor (relay) suffers from quite bad arcing. I suggested that cleaning the contacts (if this is possible-I've not seen inside the welder) might help. I also see on a circuit for another welder (180 MXE) of the same make (could not find a circuit for the 5000 MX model on line) has a bridge of capacitors, but it looks like these are not to protect the contacts but in fact power factor correction.

Maybe the contactor/relay simply needs replacing?

Any help or advice will be appreciated and passed on.

Many thanks, Rod