ryan middleton

New Member

- Messages

- 13

- Location

- Scotland

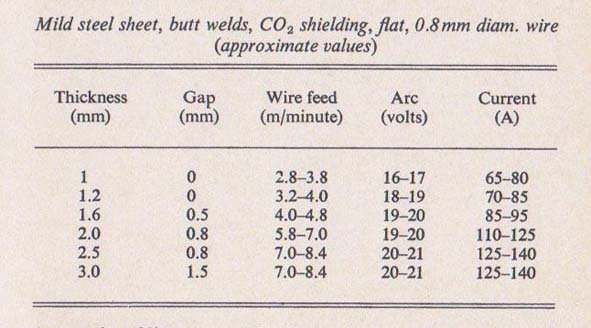

Any one got a easy amp setting guide for different thickness of metal or what to search to find one most ones I come up with are for America’s and are a bit complicated looking. Looking for a clear one that I can print out and stick inside the welder door. Thank