You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Advice on welding 10t lifting eye

- Thread starter BigDan83

- Start date

Kent

Member

- Messages

- 9,914

- Location

- Bowland, Lanacshire,UK

Heck it's done a fair amount on many jobs on repairs. You are not given an option but to be honest I am done with that stuff now, too old and too many gobby youngsters on these jobs nowOnly you can decide that mate.

Personally if I was welding a lifting eye on something I would want a qualified wps. I couldn’t live with myself if for any reason it failed and killed someone. Chances are unlikely because we have a general idea of what we need to do. You are not allowed to weld an eye on something to take load that has not been tested under Lola regs. That will finish you off behind bars if it goes badly wrong.

Kent

Member

- Messages

- 9,914

- Location

- Bowland, Lanacshire,UK

Oh yes 10t and I would bottle it alsoI've welded a few small ones on site. Two hundred kilos max. Never had a problem. But 200kg is a long way of 10t.

Richard.

Member

- Messages

- 18,043

- Location

- Cambridgeshire

Heck it's done a fair amount on many jobs on repairs.

Yes lots of naughty practice goes on on sites and it’s often addressed with a blind eye to get the job done. A lot of uk sites have this wonderful way of letting things slide until something awful happens then they over react for a couple of weeks and go in completely the other direction and make life unworkable.

I’m surprised it’s something you entertained tbh. Your usually pretty hot on stuff like that and your paper work/ insurance etc I get the impression from your posts is in order.

I can tell you now your public liability insurance will not cover someone getting hurt as a result of welding an tested lifting eye with no wps or in date codes.

It’s always fine till someone gets hurt. Then it’s not fine for a few weeks until the dust settles then it’s fine again.

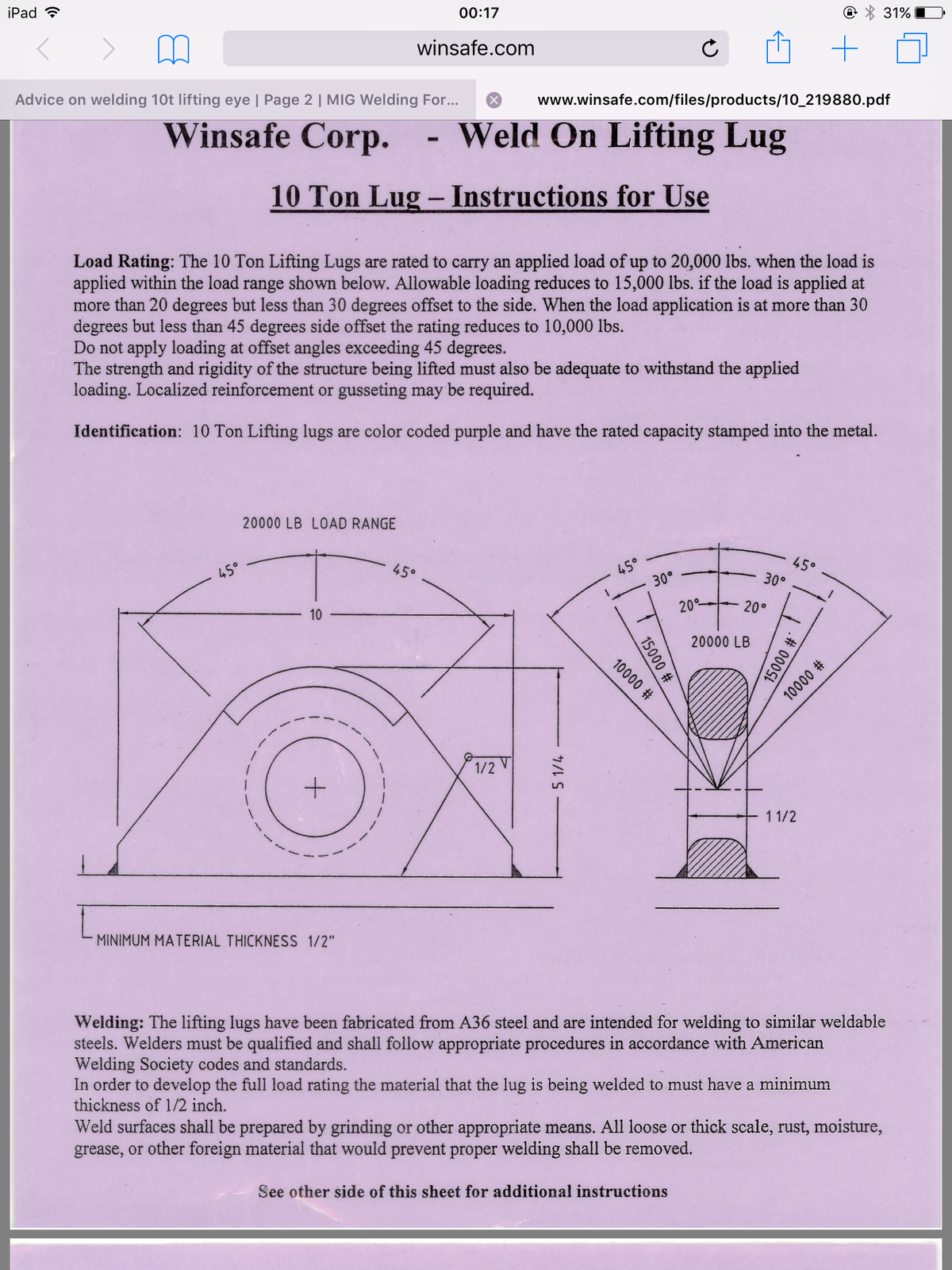

Quick Google shows very similar looking product and data sheet here. 1/2” sheet minimum. Weld required by qualified welder.

http://www.winsafe.com/productdetails/industrial-access-power-generation/weld-on-lifting-lugs.html

Edited as I didn’t make sense with the 1/2” bit.

http://www.winsafe.com/productdetails/industrial-access-power-generation/weld-on-lifting-lugs.html

Edited as I didn’t make sense with the 1/2” bit.

Dutch Welder

Member

- Messages

- 409

- Location

- Oss, The Netherlands

Why not make the actual eye an inverted T shape, and mill out part of the mounting plate to accept the bottom of the T, wit a square hole in the middle to let the leg of the T pass up.

Then you can weld it on both sides, but also have the parts itself in a way they can not come apart

Then you can weld it on both sides, but also have the parts itself in a way they can not come apart

Pete.

Member

- Messages

- 14,967

- Location

- Kent, UK

I'm no expert and could very well be wrong but is a 50mm plate for the eye a bit overkill for just 10tons?

If there is scope to loose some of the width, you will have more room for weld.

Just what I thought. A single 16mm diwydag bar has better than 19 tons capacity why the hell would you want a 50mm plate. That thing looks over-specced and badly thought out.

WorkshopChris

Member

- Messages

- 4,987

- Location

- South East Essex

Just what was going through my mind everything about the parts in the pic look wrong.Just what I thought. A single 16mm diwydag bar has better than 19 tons capacity why the hell would you want a 50mm plate. That thing looks over-specced and badly thought out.

No room for bolts, and a way ott for 10 tons.

- Messages

- 14,781

- Location

- UK

Yeah, it's a lash up

10T lifting eye i'd expect:

Geometry, plate thickness/size, bolt centres, weld sizes etc designed by a structural engineer

Plates cut, material test certs provided

WPS in place

BS qualified welding opp

Pre heat temps checked, weld leg lengths checked

Dye pen check in house as a good measure

100% NDT

Load tested by a qualified testing house

Test certs for fixings

Bolted in place then in situ load test SWL & 25%

This isn't a 'weld this mate' job.

Don't weld it.

10T lifting eye i'd expect:

Geometry, plate thickness/size, bolt centres, weld sizes etc designed by a structural engineer

Plates cut, material test certs provided

WPS in place

BS qualified welding opp

Pre heat temps checked, weld leg lengths checked

Dye pen check in house as a good measure

100% NDT

Load tested by a qualified testing house

Test certs for fixings

Bolted in place then in situ load test SWL & 25%

This isn't a 'weld this mate' job.

Don't weld it.

brightspark

Member

- Messages

- 41,348

- Location

- yarm stockton on tees

would u really want to put your ass on the line if it wasn't your every day job and someone used it

Bill Edwards

Member

- Messages

- 4,935

- Location

- Scarborough, North Yorkshire

I think you could get about 1/4 of the required fillet size before ordinary bolt heads wouldn't fit, never mind with washers fitted. I suppose you might be able to Vee out a lump either side but I certainly wouldn't want to do that.

Even if you can get enough weld metal in place - perhaps if caphead bolts are used - I still wouldn't want to touch it. It's 'mild steel' - but what if it actually isn't and therefor unweldable without special consumables and procedures? It could leave your bench looking just fine but then it breaks through no fault of the man laying beads and we know what can then happen.

Sometimes your only sensible option is to say no, difficult though it might be.

Even if you can get enough weld metal in place - perhaps if caphead bolts are used - I still wouldn't want to touch it. It's 'mild steel' - but what if it actually isn't and therefor unweldable without special consumables and procedures? It could leave your bench looking just fine but then it breaks through no fault of the man laying beads and we know what can then happen.

Sometimes your only sensible option is to say no, difficult though it might be.

thats not a 10T lifting eye, i would say its more like 50T

when i built the recovery tug i profiled out simalar to put shakel pins through for cabels and chains they take a hell of a lot more than 10T they were just nailed on with a big mig ( quite a few runs ) but there again that was only ever for pulling not lifting.

sadly that machene is parked up semi abandoned as it's officaly condemed. as its easy pickings for a clipboard warrior to attack as there is no paperwork at all for it or any of the bits, funny tho it soon becomes officaly uncondemmed when something really big gets really stuck. but a winch with 200T of line pull mounted on tracks with nearly 1000 bhp, hydralic ground anchors ect would take some replaceing, i'd be scared of the job if was asked to build another, how you'd go about such a thing and make it "safe" and covering ones backside, i dread to think what it'd cost to do properly

when i built the recovery tug i profiled out simalar to put shakel pins through for cabels and chains they take a hell of a lot more than 10T they were just nailed on with a big mig ( quite a few runs ) but there again that was only ever for pulling not lifting.

sadly that machene is parked up semi abandoned as it's officaly condemed. as its easy pickings for a clipboard warrior to attack as there is no paperwork at all for it or any of the bits, funny tho it soon becomes officaly uncondemmed when something really big gets really stuck. but a winch with 200T of line pull mounted on tracks with nearly 1000 bhp, hydralic ground anchors ect would take some replaceing, i'd be scared of the job if was asked to build another, how you'd go about such a thing and make it "safe" and covering ones backside, i dread to think what it'd cost to do properly

Parm

Respect The Sound System

- Messages

- 17,874

- Location

- Towcester

Some very good advice offered from competent experienced welders.

Now to look at it a different way as I know nothing about welding.

If it all goes pear shaped your directly in the firing line, your competence etc will all be questioned as part of any investigation and from what I've seen your employer won't be much cop.

Like the others have said, take a wide berth and walk away

Now to look at it a different way as I know nothing about welding.

If it all goes pear shaped your directly in the firing line, your competence etc will all be questioned as part of any investigation and from what I've seen your employer won't be much cop.

Like the others have said, take a wide berth and walk away

BigDan83

Member

- Messages

- 124

- Location

- Manchester England

Thanks for the great response lads, I've not touched these. There's far to much involved in doing these than just telling me to do a 25mm fillet. I would be confident that i could do them, but I ain't taking a chance with such little info off my gaffer. I'll keep you all posted.

Cheers Dan

Cheers Dan

Revs1972

Member

- Messages

- 1,797

- Location

- Torquay, UK

We lifted a 30 ton structure the other week, using 4 No 400 mm long lifting lugs which were fabricated from 20 thick plate and welded 8 fillet weld to another 20 thick plate.

This was then bolted to another 20 thick plate ( sandwiching a 305 deep UB section) using 4No M24 grade 8.8 studs. All designed by the structural engineer.

I was dubious about the 8fw as it just didn't look right, but it all worked just lovely.

this is an off the shelf lifting lug (albeit American market). Your thickness looks about the same but it's only a 12 fw full profile weld shown on that.

What they are asking you to make look like positive lifting brackets. They should be designed by a SE and there should be paperwork to go with them (I.e design calcs telling you what welds to put on )

This was then bolted to another 20 thick plate ( sandwiching a 305 deep UB section) using 4No M24 grade 8.8 studs. All designed by the structural engineer.

I was dubious about the 8fw as it just didn't look right, but it all worked just lovely.

this is an off the shelf lifting lug (albeit American market). Your thickness looks about the same but it's only a 12 fw full profile weld shown on that.

What they are asking you to make look like positive lifting brackets. They should be designed by a SE and there should be paperwork to go with them (I.e design calcs telling you what welds to put on )

winchman

Member

- Messages

- 6,321

- Location

- Merseyside

Thats some excellent advice.Some very good advice offered from competent experienced welders.

Now to look at it a different way as I know nothing about welding.

If it all goes pear shaped your directly in the firing line, your competence etc will all be questioned as part of any investigation and from what I've seen your employer won't be much cop.

Like the others have said, take a wide berth and walk away

This should only be done with a full set of Docs including Material certs, calls drawings etc, basically you should only be welding it exactly as the designer specifies in the docs they supply with the request.

Anything like this I have come across before its used would be fully tested with a load by an independent lifting gear inspector so we then hold a proper test cert.

Kent

Member

- Messages

- 9,914

- Location

- Bowland, Lanacshire,UK

Only under subcontractor same trade hence not my insurance. As I say I am passed all that now thank goodness. The wife thinks otherwise but it ain't happeningYes lots of naughty practice goes on on sites and it’s often addressed with a blind eye to get the job done. A lot of uk sites have this wonderful way of letting things slide until something awful happens then they over react for a couple of weeks and go in completely the other direction and make life unworkable.

I’m surprised it’s something you entertained tbh. Your usually pretty hot on stuff like that and your paper work/ insurance etc I get the impression from your posts is in order.

I can tell you now your public liability insurance will not cover someone getting hurt as a result of welding an tested lifting eye with no wps or in date codes.

It’s always fine till someone gets hurt. Then it’s not fine for a few weeks until the dust settles then it’s fine again.

I'd have that drilled through the bottom plate and some big countersunk bolts through it or modified so the top goes all the way through the bottom plate to weld both sides.

That is what I would do. Looks more like 100 tons not 10!