Greetings,

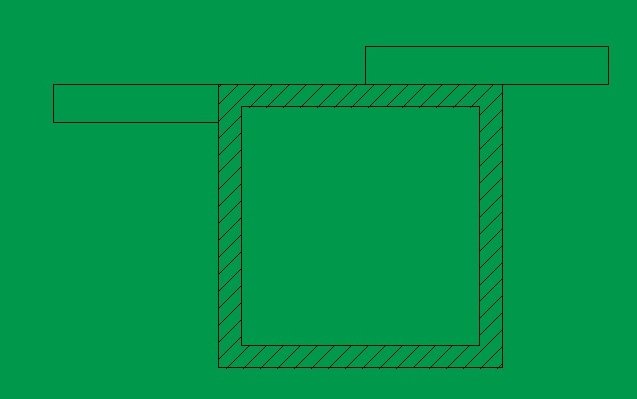

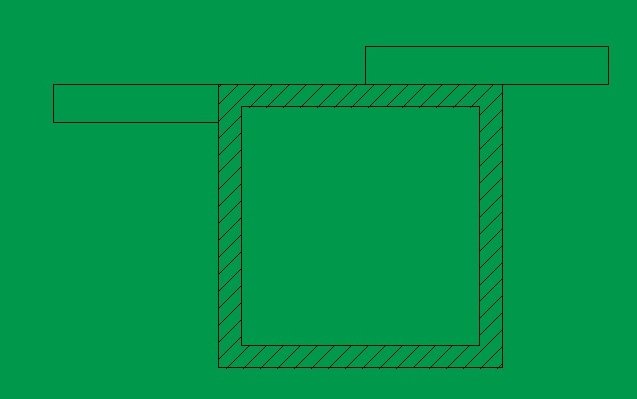

I have never welded before, however I have a project coming up that will require me to weld a frame from 75x75x6 square tube, as well as welding of short lengths of 10 -15 mm thick mild steel plate to the square box in a manner as shown below:

I do not have a welder atm but I feel this is a good opportunity to gain a new skill. Apart from this project my future welding activities will most likely always remain on an infrequent DIY level. I need some advice on what machine I should get that will weld steel of uneven thickness as per the image above. Would fillet joints be the most appropriate? The joints will not carry any structural loads. I would like to have my own welder at home.

I have never welded before, however I have a project coming up that will require me to weld a frame from 75x75x6 square tube, as well as welding of short lengths of 10 -15 mm thick mild steel plate to the square box in a manner as shown below:

I do not have a welder atm but I feel this is a good opportunity to gain a new skill. Apart from this project my future welding activities will most likely always remain on an infrequent DIY level. I need some advice on what machine I should get that will weld steel of uneven thickness as per the image above. Would fillet joints be the most appropriate? The joints will not carry any structural loads. I would like to have my own welder at home.