citizen kane

Member

- Messages

- 265

I'm reinstating an Aciera F3 and I'm a little confused as to what to use in the vertical head.

Through its production life the design of the standard vertical head seems to have changed.

This seems to be the earliest version. I have managed to track down the manual for this version and its oil filled, you can see the sight glass on the front. The oil is for lubrication of the gears, from what I can tell the lower bearing is greased and the upper oil fed from the nipple.

And this one the latest version. Again,manged to track down the manual and on this version there is no sight glass and the gears and bearings are greased.

At some point there seems to have been a transition between heads, this is what mine looks like. Seems similar to the later one but with an oil sight glass and nipple for the top bearing. Not sure if it should be oil or grease for the gears as I cant find a manual for this head.

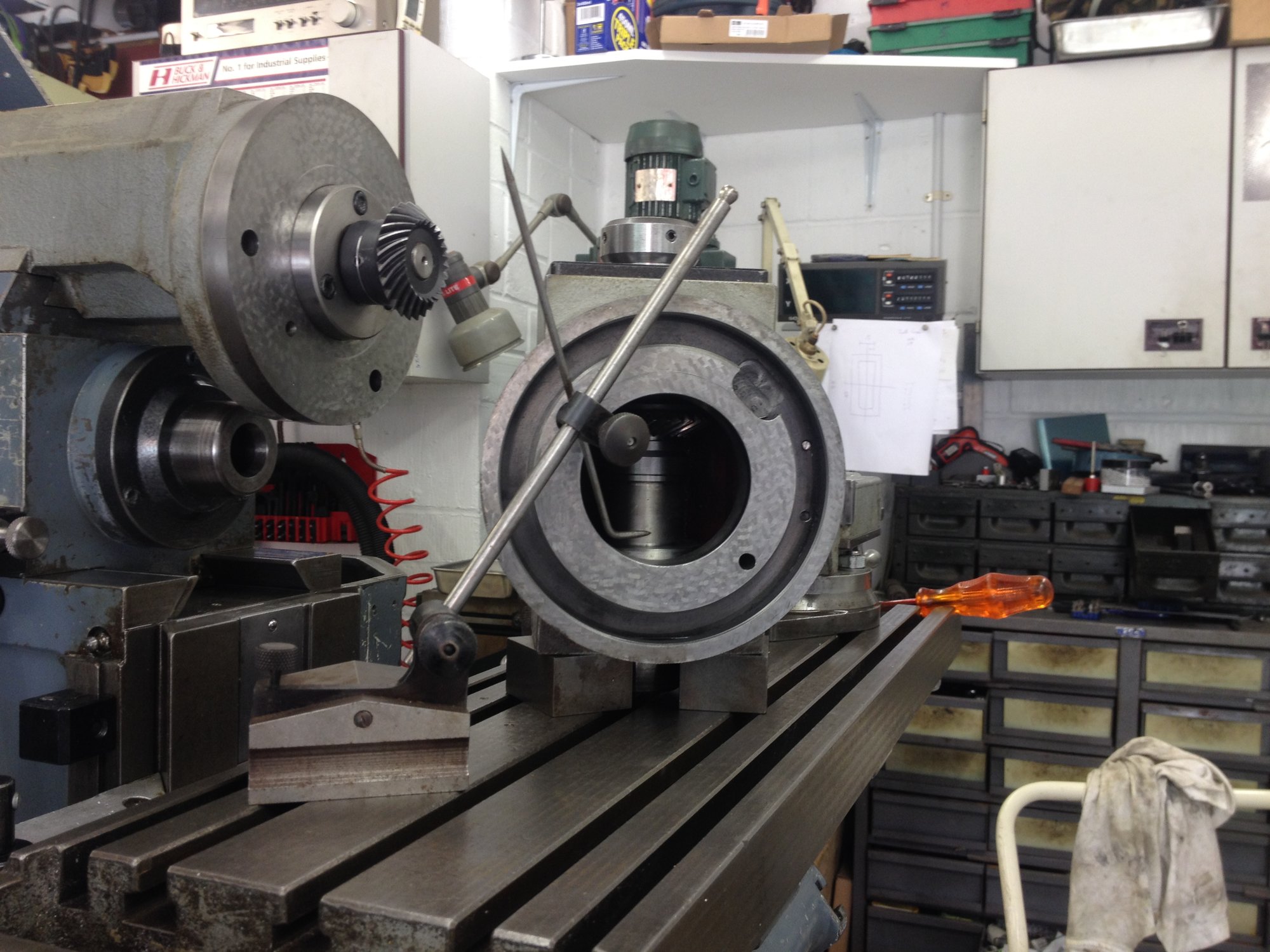

With the scribe block set to the mid fill point on the sight glass this picture shows how far the oil level will be inside the head. The part of the spindle that would be submerged in oil doesn't rotate and the drive gear wouldn't dip into the oil so I cant see how the gears would be lubricated does that mean that despite the oil level sight glass this one probably needs the gears greasing, any body know for sure?

Through its production life the design of the standard vertical head seems to have changed.

This seems to be the earliest version. I have managed to track down the manual for this version and its oil filled, you can see the sight glass on the front. The oil is for lubrication of the gears, from what I can tell the lower bearing is greased and the upper oil fed from the nipple.

And this one the latest version. Again,manged to track down the manual and on this version there is no sight glass and the gears and bearings are greased.

At some point there seems to have been a transition between heads, this is what mine looks like. Seems similar to the later one but with an oil sight glass and nipple for the top bearing. Not sure if it should be oil or grease for the gears as I cant find a manual for this head.

With the scribe block set to the mid fill point on the sight glass this picture shows how far the oil level will be inside the head. The part of the spindle that would be submerged in oil doesn't rotate and the drive gear wouldn't dip into the oil so I cant see how the gears would be lubricated does that mean that despite the oil level sight glass this one probably needs the gears greasing, any body know for sure?