Lazurus

Member

- Messages

- 1,083

- Location

- Norfolk uk

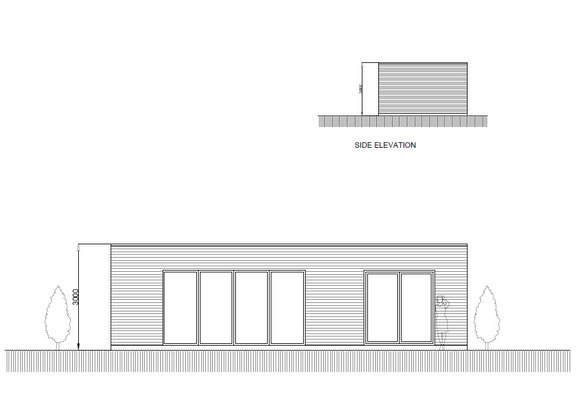

I am in the position of having a purpose-built workshop for the first time in my life, this is just prior to retirement. I am looking at a 10m x 5m workshop in our back garden (subject to planning) It is currently in the design and application process. Initially I was going for a traditional double skin brick construction with insulation in keeping with the garage and bungalow – however I like the idea of a more modern looking dark grey cladding. The attached drawing shows the preliminary design. I am looking for low maintenance and, in the future, when I can no longer use a workshop converting the inside to an annex or sun room. So, I intend to put water and drainage utilities in at the point of build ready for future change of use. Can I ask advice on the best construction method and what is required in structural design to use exterior cladding, and, which type would be best?